19 Troubleshooting

19.1 Troubleshooting

312

GC-2010 Plus

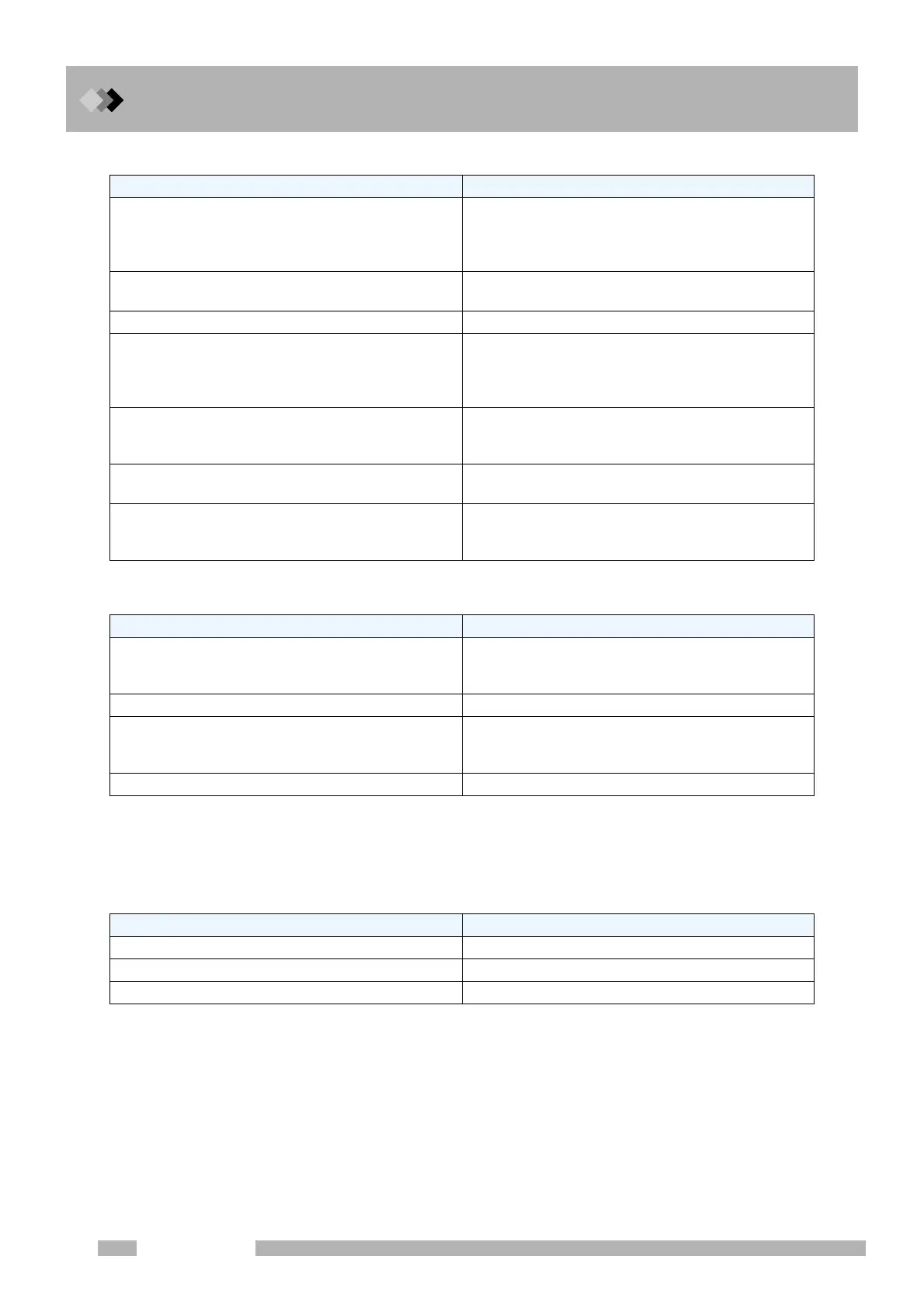

2. The FID baseline is fluctuating

3. Baseline noise is high

If the jet is damaged, replace it. If the collector is coated with white powder, contact your

shimadzu representative for replacement.

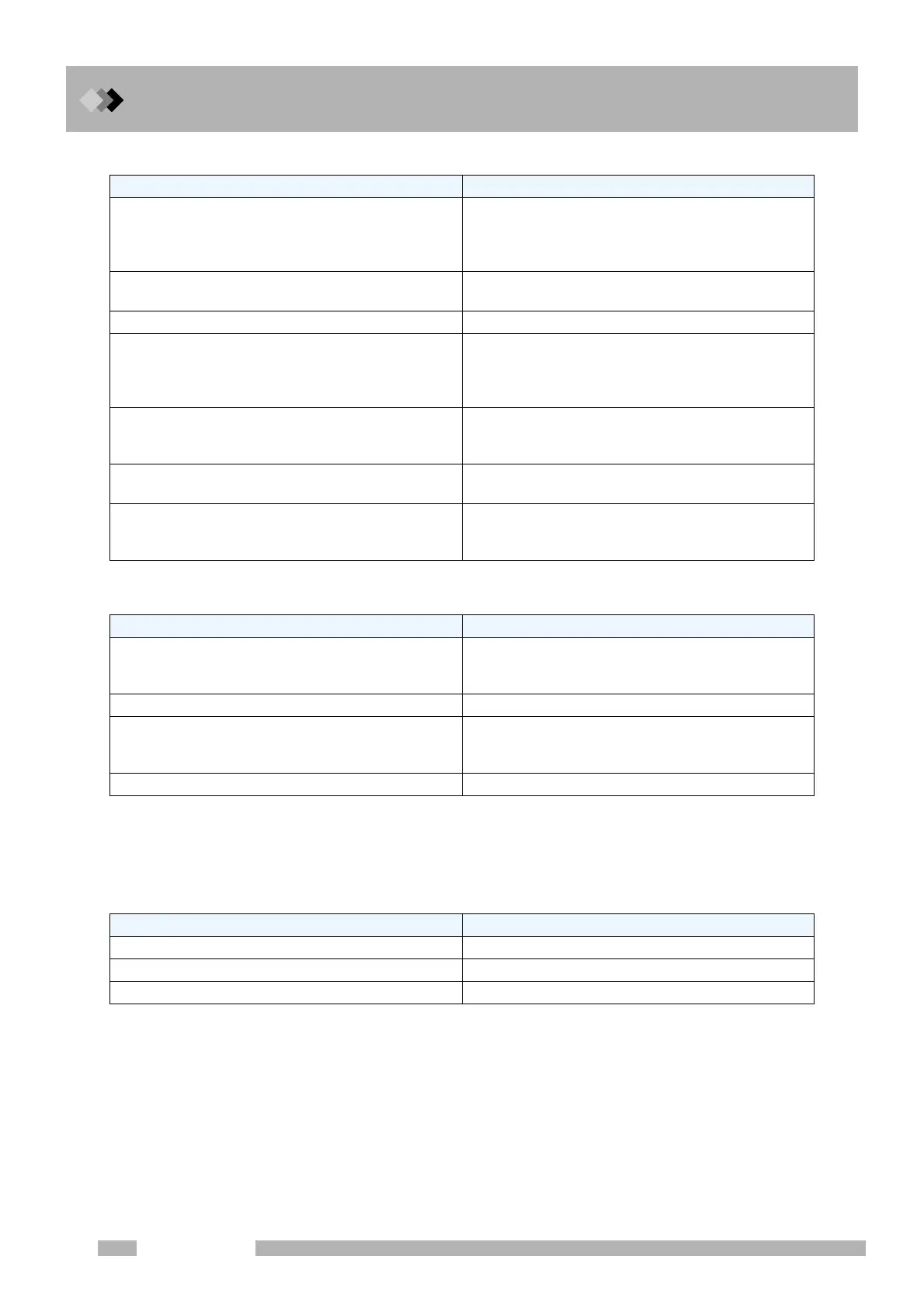

19.1.3.2 TCD

1. The detector cannot be zeroed

Turning on the TCD current when oxygen is present in the cell can oxidize or blow out

the filament, making it impossible to zero the detestor. If the filament blows out, the cell

must be replaced; contact your Shimadzu reprensentative.

Possible Cause Solution

Carrier gas leaks.

Tighten leaking connections.

Replace tubing or septum.

(Refer to “2.6 Gas supply plumbing” in Instruction

Manual.)

Carrier gas or make up gas quality is poor.

Replace gas with higher purity gas.

Provide a molecular sieve filter in the gas flow line.

Molecular sieve filter is saturated. Recondition the molecular sieve filter.

Injection port is contaminated.

Inspect the glass insert. Clean or replace the glass

insert.

(Refer to “18.5 Inspection and Maintenance: Glass

Insert” in Instruction Manual.)

Compressed air is contaminated (the baseline

fluctuates according to the compressor pressure).

Install a silica gel trap on either end of the pressure

regulator.

Use air from a gas cylinder instead (with the FID on).

Hydrogen gas has not been flowing long enough to

replace the air in the tubing.

Wait for 30 to 60 minutes to allow the air to be

completely replaced with hydrogen.

Room temperature is not within the recommended

range and/or is fluctuating considerably.

Keep the room temperature within the recommended

range and move the system away from heat or A/C

vents, etc.

Possible Cause Solution

Carrier gas quality is poor.

Replace carrier gas with higher purity gas.

Provide a molecular sieve filter in the carrier gas flow

line.

Hydrogen gas quality is poor. Replace hydrogen gas with higher purity gas.

Gas leaks

Check the leak in injection port and column

connection area.

Tighten leaking connectors.

The quartz jet is dirty. Inspect, clean, or replace the jet.

Possible Cause Solution

Data processing unit is not connected properly. Connect them properly.

Current is “Off” Turn the current on.

Current value is too high. Set current to a lower value.

Loading...

Loading...