Technical data

170 Manual m600 basic 2.6_01

14

Slippage on the pulse generator wheel on the pulse generator

If the pulse generator is not pressed onto the conveyor belt with enough

pressure or is in contact with a very smooth surface (e. g. belt driving roll-

er), the pulse generator may occasionally slip and the m600 basic will then

receive incorrect speed information. In the print image this is apparent in

stretching in the print direction and an offset at the print head transition

points. Another problem occurs whenever heavy products are on the belt,

causing the pulse generator to jump off. In the print image this is appar-

ent in drop-outs and offsetting. If the pressing pressure on the belt is ex-

cessive, however, this may destroy the pulse generator bearing.

Pulse generator

socket

Insufficient number of pulses per revolution (less than 500)

If you print with a low belt speed or the belt is accelerated or slowed down

during printing, it is possible that the automatic adjustment of the printing

speed may not be fast enough. This will result in an imprecise print image

(stretching, compression, offsetting at the transition points between the

print heads if several print heads are used). If the speed of the belt is too

slow the m600 basic interprets this as a stop. For very slow belt speeds it

is therefore advisable to use a pulse generator with a large pulse/revolu-

tion ratio.

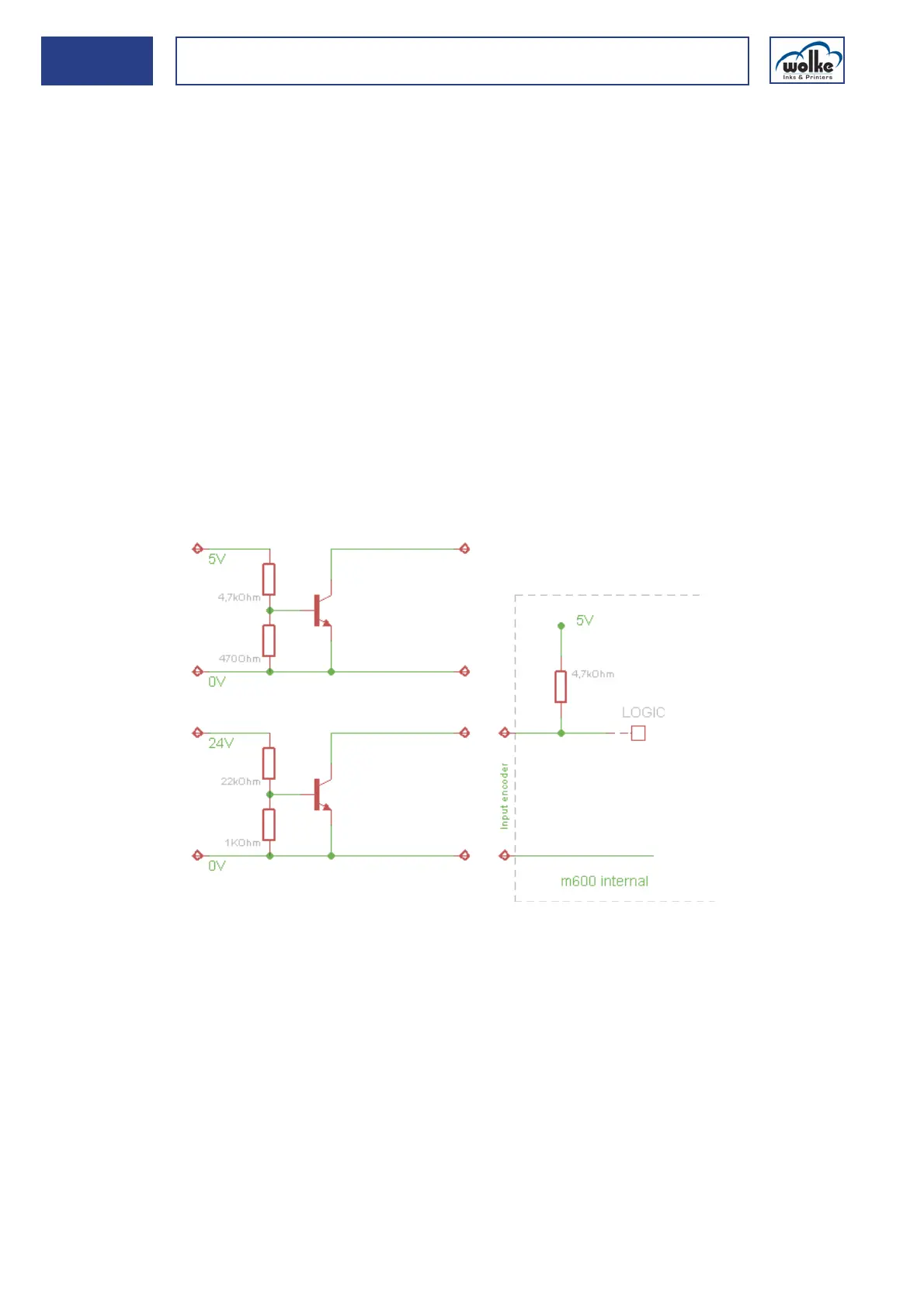

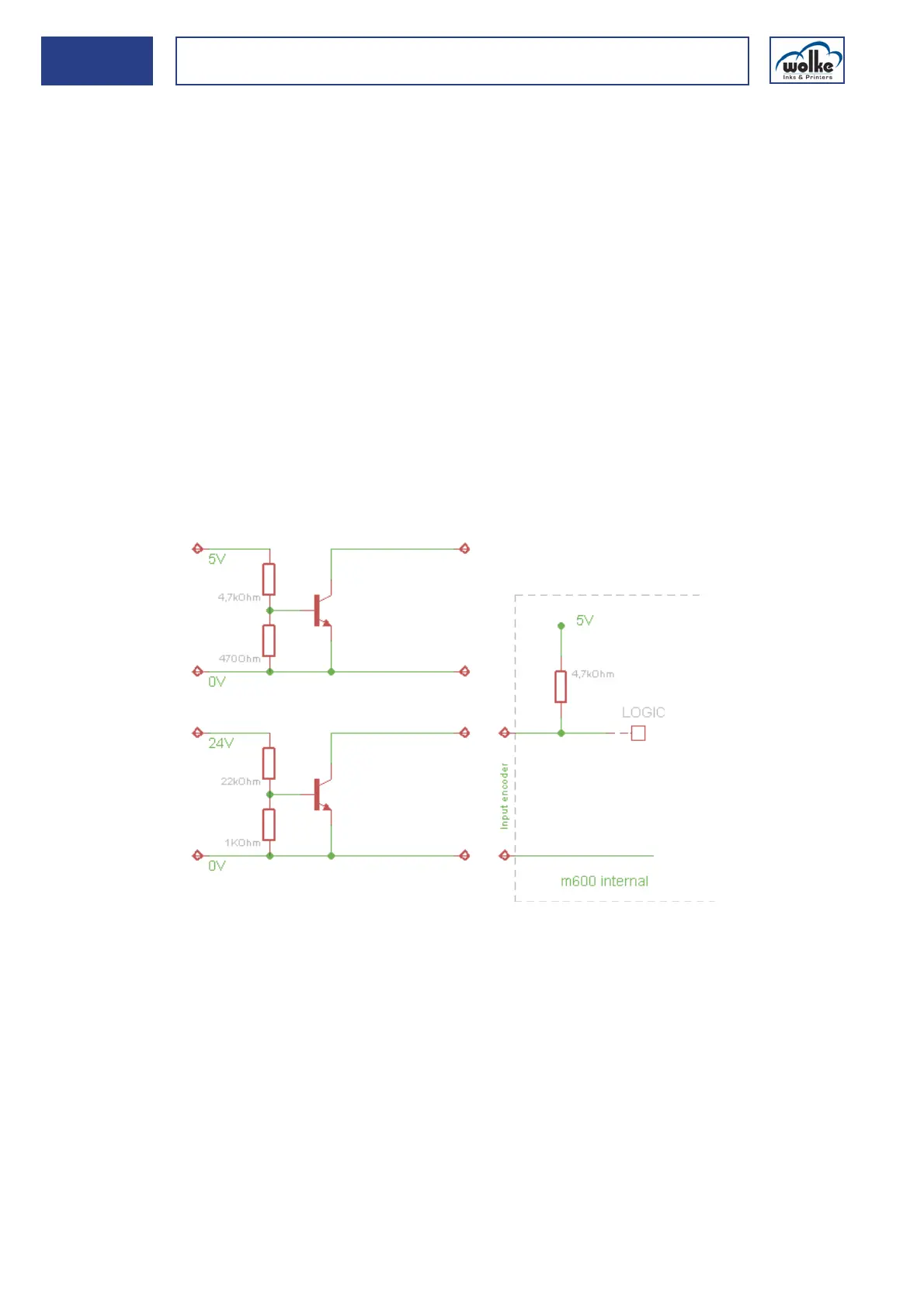

Fig. 14_244: External circuitry for shaft encoder of other manufacturers with

deviating voltage ratings

Loading...

Loading...