Troubleshooting

7

7.4 Faults

SIEPCYEUOQ2V01A Q2V Technical Manual 225

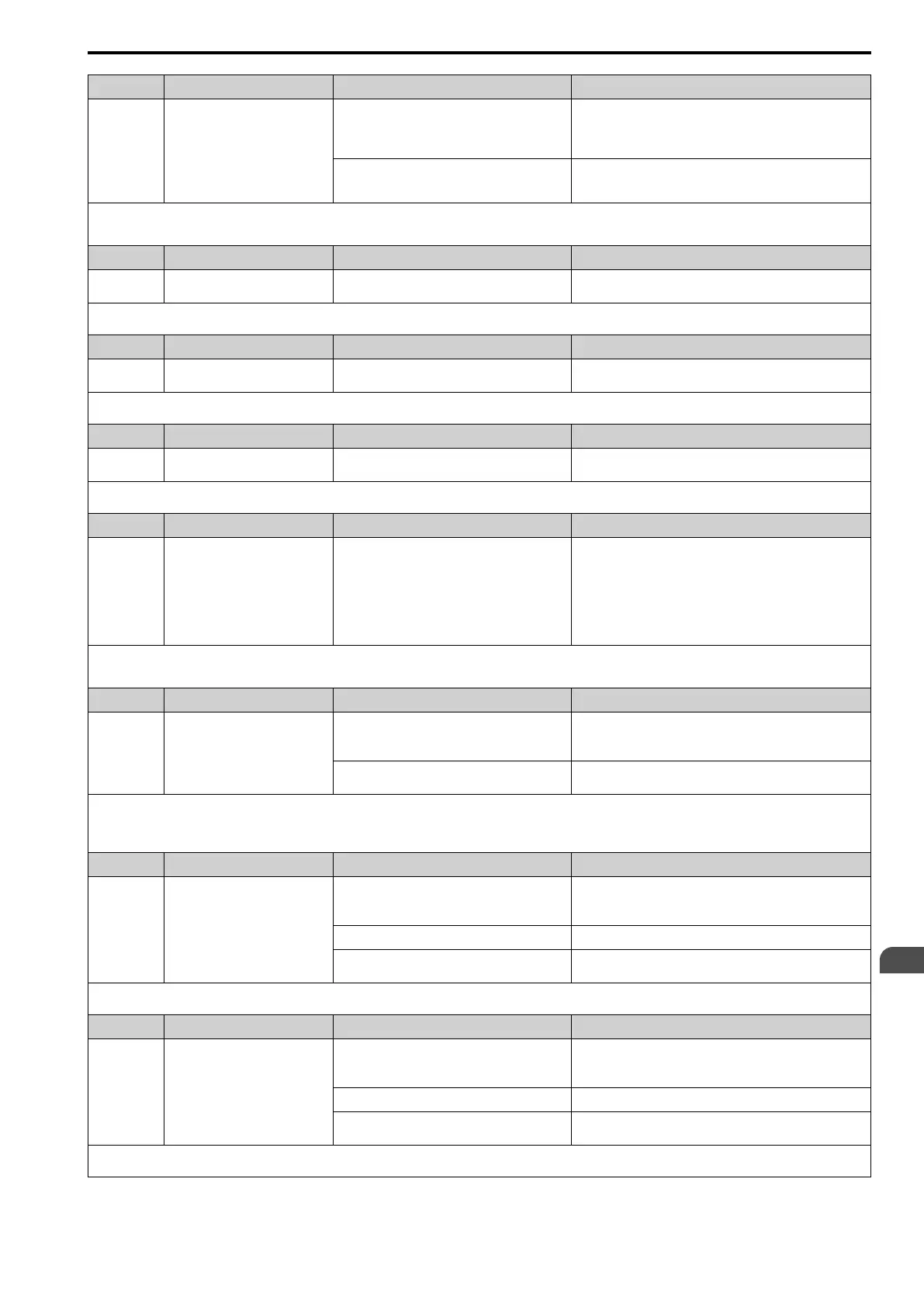

Code Name Causes Possible Solutions

qFL1

EEPROM Memory Q2pack Data

Error

There is an error in the EEPROM peripheral circuit. • Re-energize the drive.

• If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact the

manufacturer or your nearest sales representative.

There is a problem with the EEPROM data. Set A1-03 = 2220, 3330 [Init Parameters = 2-Wire Initialization,

3-Wire Initialization] to initialize the drive, then upload the

Q2pack project to the drive again.

Note:

• The drive detects this error if there is an error in the Q2pack program that was saved to EEPROM.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL2 Q2pack Fault 2

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL3 Q2pack Fault 3

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

qFL Q2pack Fault

There was a fault in the Q2pack program. Examine the Q2pack program and remove the cause of the fault.

This is not a drive fault.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

E5

MECHATROLINK Watchdog

Timer Err

The drive detected a watchdog circuit exception

while it received data from the controller.

Examine the MECHATROLINK cable connection. If this error

occurs frequently, examine the wiring and decrease the effects of

electrical interference as specified by these manuals:

• MECHATROLINK-II Installation Guide (MECHATROLINK

Members Association, manual number MMATDEP011)

• MECHATROLINK-III Installation Manual

(MECHATROLINK Members Association, publication

number MMATDEP018)

Note:

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the stop method set in F6-25 [MLII Watchdog Error Sel].

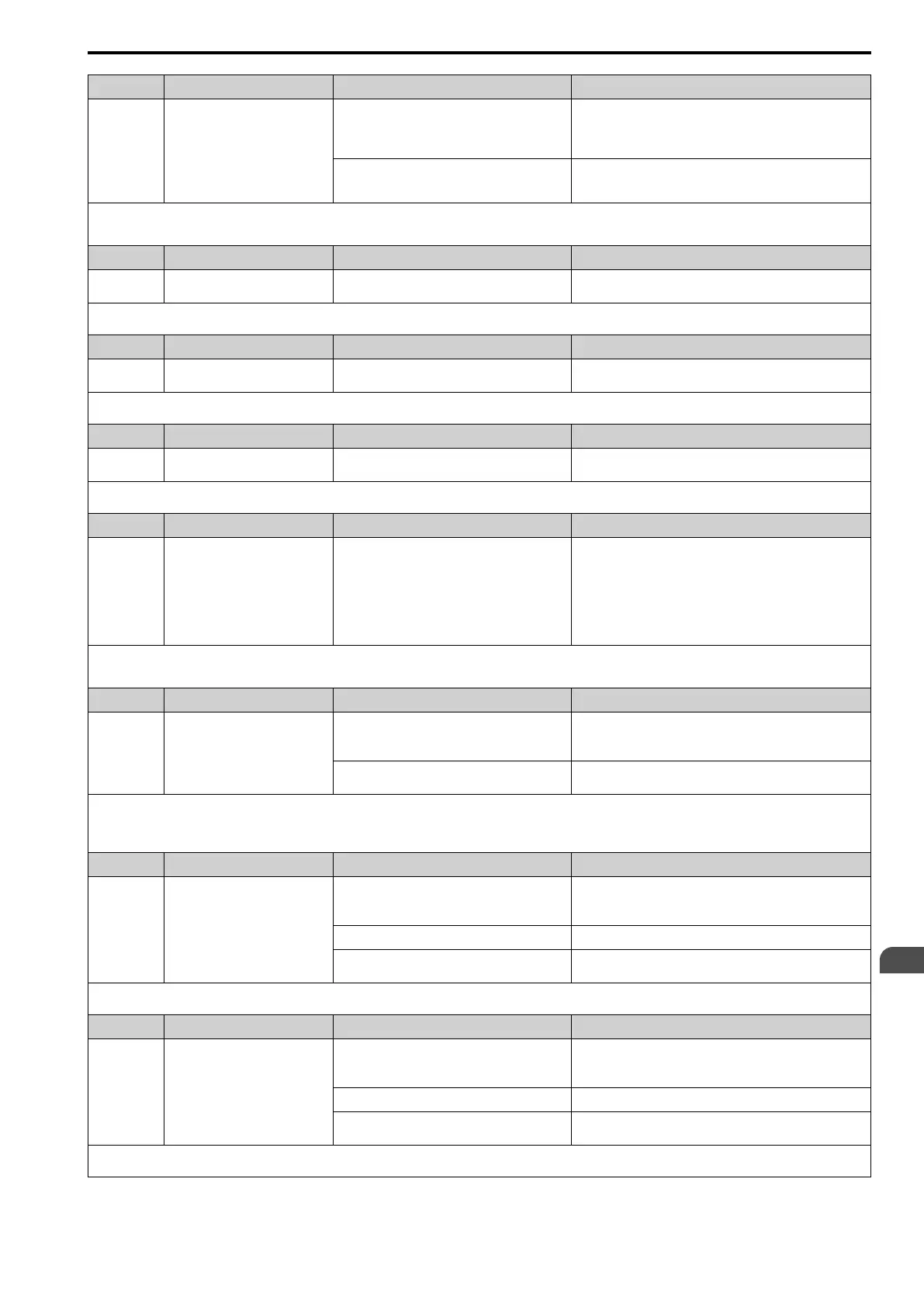

Code Name Causes Possible Solutions

EF0 Option Card External Fault

The communication option received an external

fault from the controller.

1. Find the device that caused the external fault and remove the

cause.

2. Clear the external fault input from the controller.

A programming error occurred on the controller

side.

Examine the operation of the controller program.

Note:

• The drive detects this fault if the alarm function on the external device side is operating.

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the stop method set in F6-03 [Comm Ext Flt Select (EF0)].

Code Name Causes Possible Solutions

EF1 External Fault (Terminal DI1)

MFDI terminal DI1 caused an external fault through

an external device.

1. Find the device that caused the external fault and remove the

cause.

2. Clear the external fault input in the MFDI.

The wiring is incorrect. Correctly connect the signal line to MFDI terminal DI1.

External Fault [H1-01 = 20 to 2B] is set to MFDI

terminal DI1, but the terminal is not in use.

Correctly set the MFDI.

Note:

Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

EF2 External Fault (Terminal DI2)

MFDI terminal DI2 caused an external fault through

an external device.

1. Find the device that caused the external fault and remove the

cause.

2. Clear the external fault input in the MFDI.

The wiring is incorrect. Correctly connect the signal line to MFDI terminal DI2.

External Fault [H1-02 = 20 to 2B] is set to MFDI

terminal DI2, but the terminal is not in use.

Correctly set the MFDI.

Note:

Do a Fault Reset to clear the fault.

Loading...

Loading...