6A-34 ENGINE REPAIR

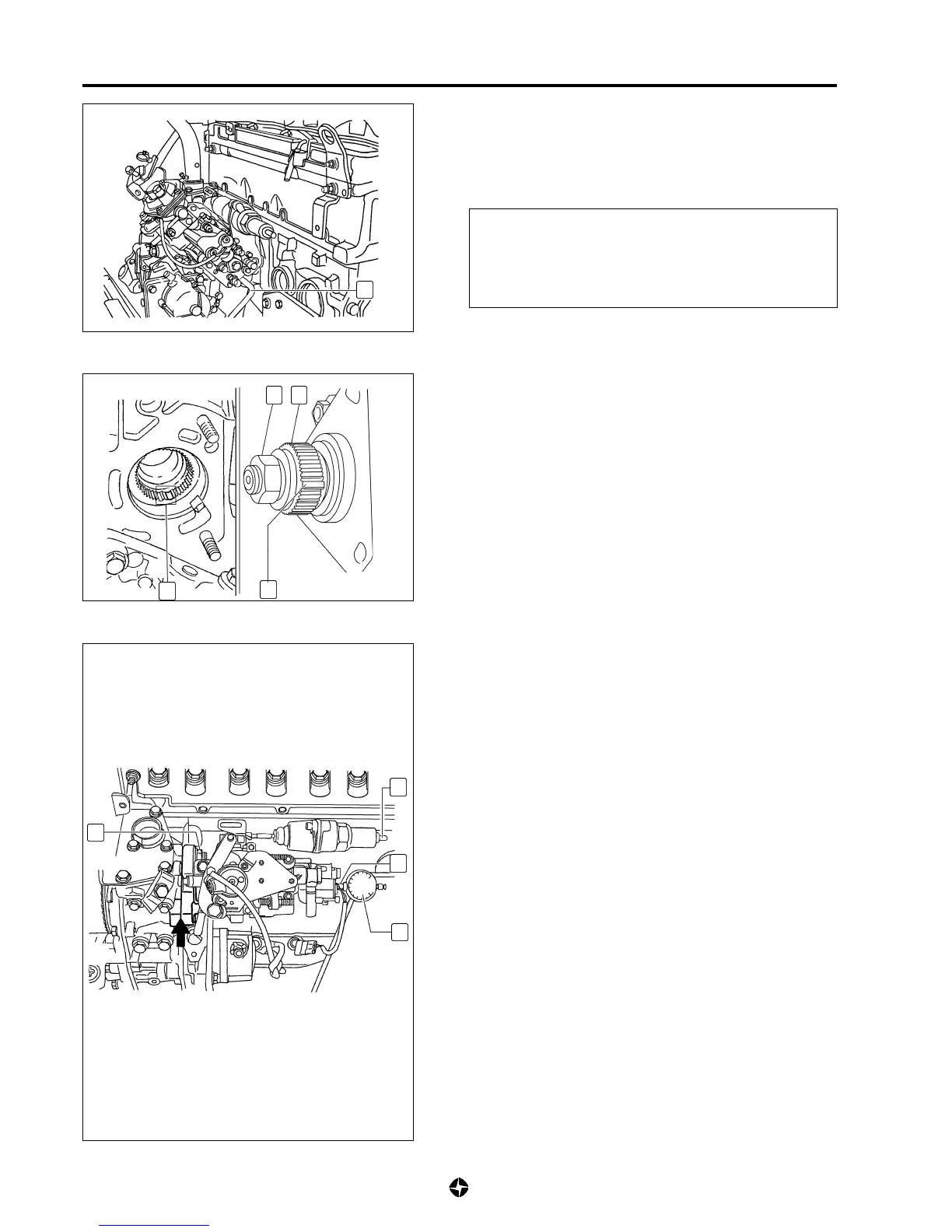

6) Remove nuts fixing injecting pump and take it away.

NOTE:

The lower nut place near the block is removed with

key (F) ref. 790997.

CAUTION:

Plug with appropriate caps the conductions which

have been opened. Entry of some alien body in this

conductions could seriously damage the injection

system.

Installation and setting of injecting pump

1) Install injection pump in the appropriate place of auxiliary

organs group as follows:

• Check correct setting of timing (see operation 5

th

of removal).

• Put front to front channelling (14) from drive shaft and the

guiding tooth (15) from hub (16) and install the pump.

NOTE:

If it is deemed to substitute pump hub (16), use tool ref.

790992 to keep in place the hub during removal or

installation of nut (17), and tool ref. 790991 to extract

hub.

Tightening torque for nut (17) of injecting pump grooved

hub: 8 Kg-m (80 Nm)

• Align marks ( ) to be found in the housing sump and in

the auxiliary organs group housing (if you are fitting the

same pump).

• Install nuts (18) fixing injecting pump without tighten too

much.

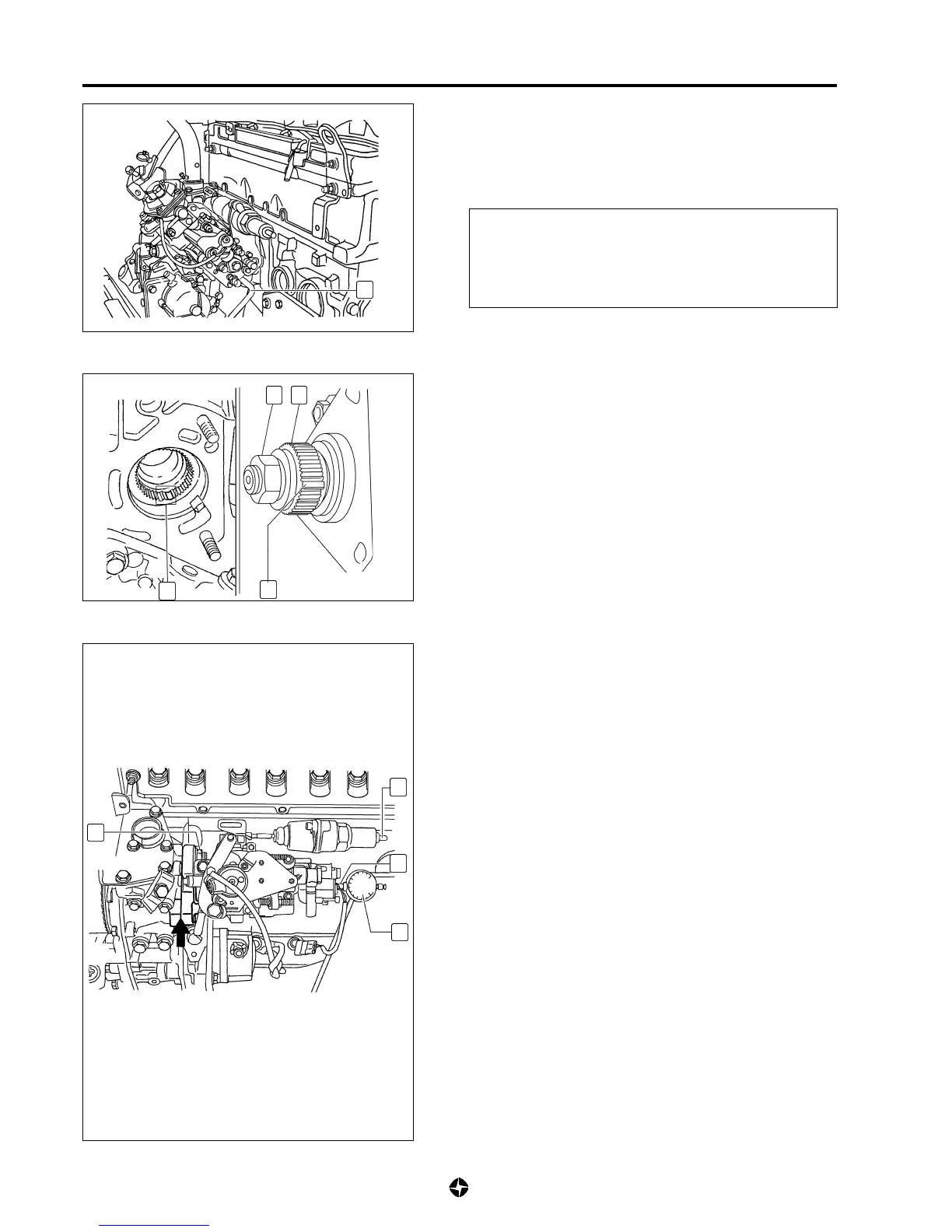

2) Inactivate K.S.B. device (9) supplying tension from the vehicle

during the setting up of pump.

NOTE:

The K.S.B. device is inactivated when the advancing

lever is not under loading.

3) Take away cap located in the pump closing screw and fit

adapter (C) ref. 790966; be sure that the tip is in contact

with the distributing piston. Install dial gauge (D) ref. 790967

in such a way that the measuring tip advances previously

some 3-mm.

4) Withdraw tool ref. 790965 which fixes the driving gear (12)

position of auxiliary organs group.

5) Turn slowly crankshaft in the opposite direction to rotation

till dial gauge (D) shows the L.D.C. of distributor piston;

then put into zero reading the dial gauge.

F

17

16

15

14

18

9

C

D

¨

Loading...

Loading...