ENGINE REPAIR 6A-41

NOTE:

• Before using again the screws of engine flywheel,

measure with a micrometer the diameter on threading.

Never the diameter should be below 10.8 mm; otherwise,

replace them.

• Because the play between flywheel bolts and their pass

holes, the relative position of flywheel from crankshaft

must be determined before retighten flywheel

permanently.

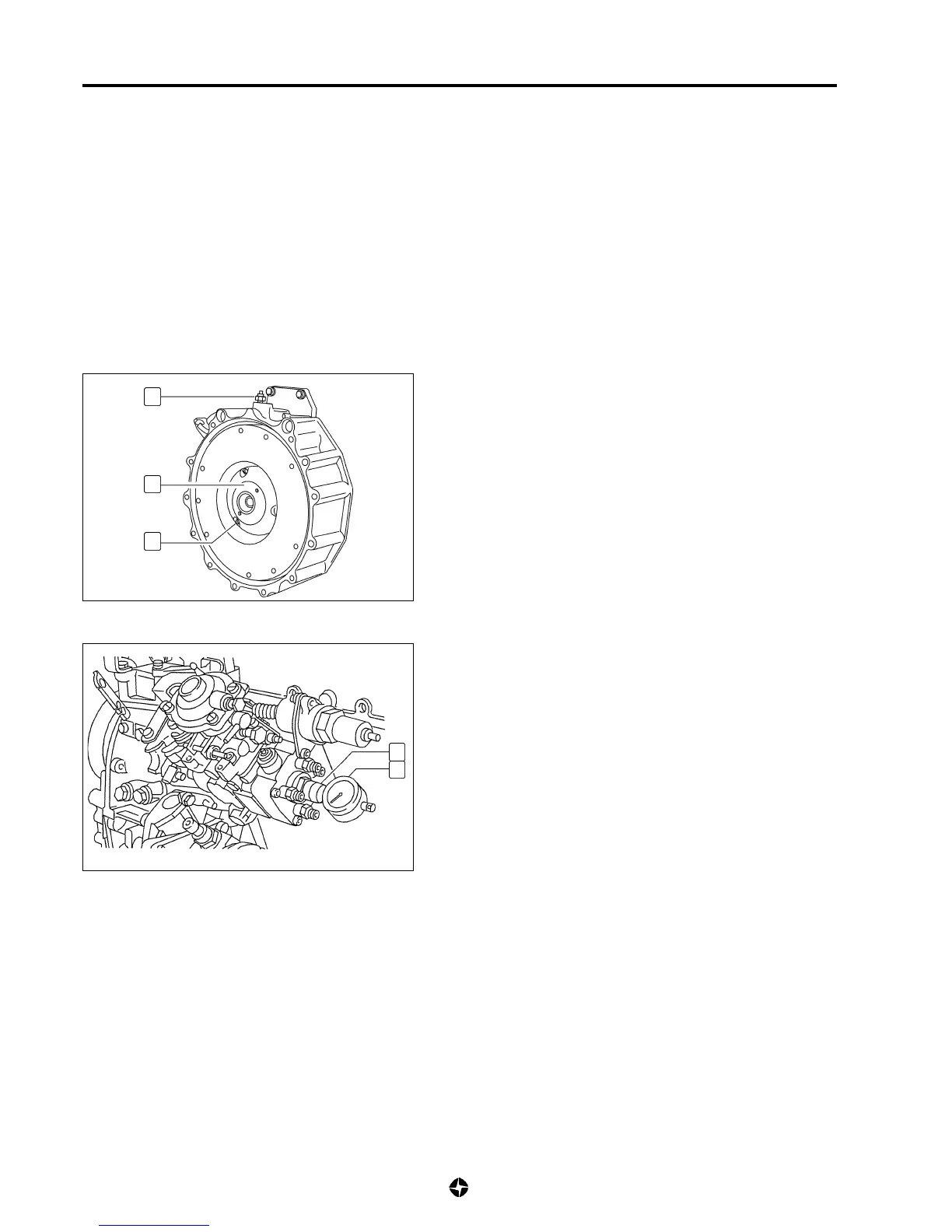

3) Assemble the plate for bearing support (5) using screws (6)

and tighten them to the specified tightening torque.

Tightening torque for screws on plate for bearing

support:

1,8 ÷ 2,8 Kg-m (18 ÷ 28 Nm)

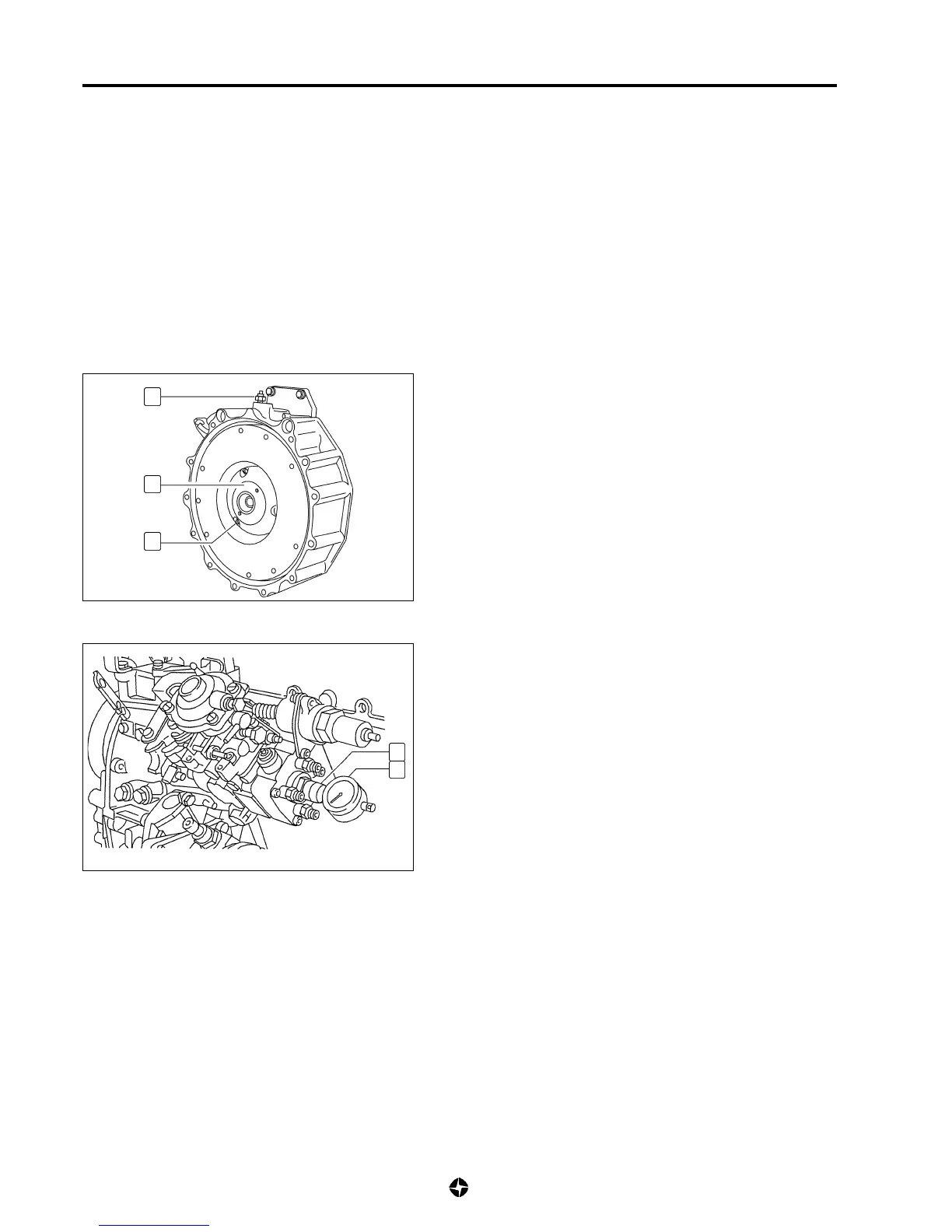

4) Install the r.p.m. Sensor (8), adjusting it as specified in 6C-55

FUEL SUPPLY SYSTEM AND EXHAUST CONTROL.

5) Withdraw tool blocking the flywheel and centring tool ©.

Dismantle adapter tool (D) and compactor (E). Assemble

cover on register of injection pump tightening it moderately.

6) Proceed to assembly reversing the dismantling order. Apply

the specified tightening torque's and those specified in the

complementary tasks.

Tightening torque of nuts at sound proofing cover:

0,5 Kg-m (5 Nm)

D

E

5

6

8

Loading...

Loading...