6A-98 ENGINE REPAIR

CRANKSHAFT REPAIR

Revision and measurement of crankshaft

Revision

1) Clean thoroughly crankshaft and check carefully there are

no knockings, scratches, signs of gripping or wear.

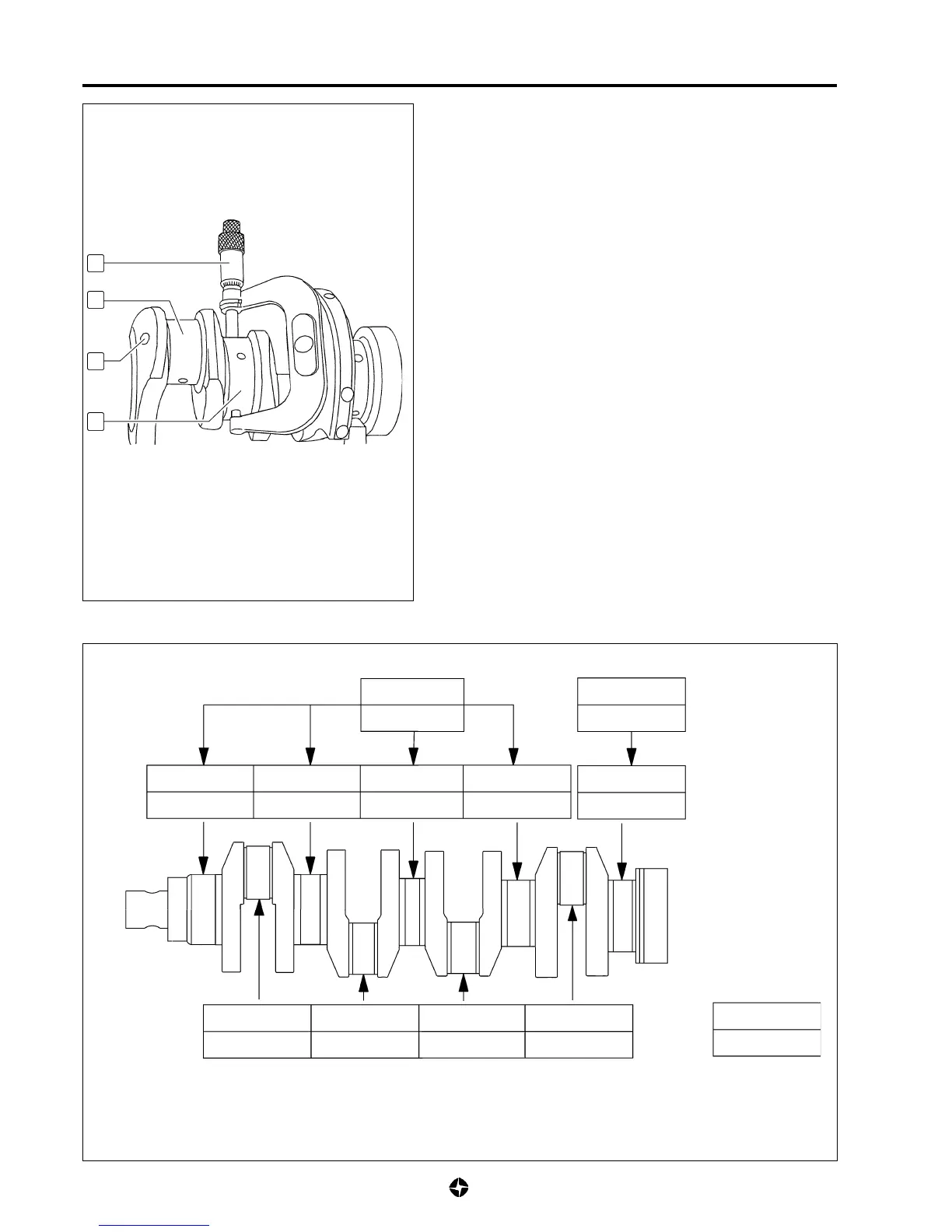

2) Verify caps of oil tunnels (3) just in case they show rust or

lack of impermeability. If the caps show signs of

abnormalities, replace them and asess impermeability.

Pressure for controlling the crankshaft caps

impermeability: 1,5 Kgxcm

2

NOTE:

If you appreciate in the journal of connecting rods or

main bearings signs of gripping, knockings , scratches

or excessive wear, it will be necessary to carry out an

oversize mechanical rectifying.

1

2

3

4

Crankshaft measurement of the

1) Using a micrometer (1) proceed to measure the journal of

connecting rods (2) and main bearing (4) to determine the

diameter to be reduced.

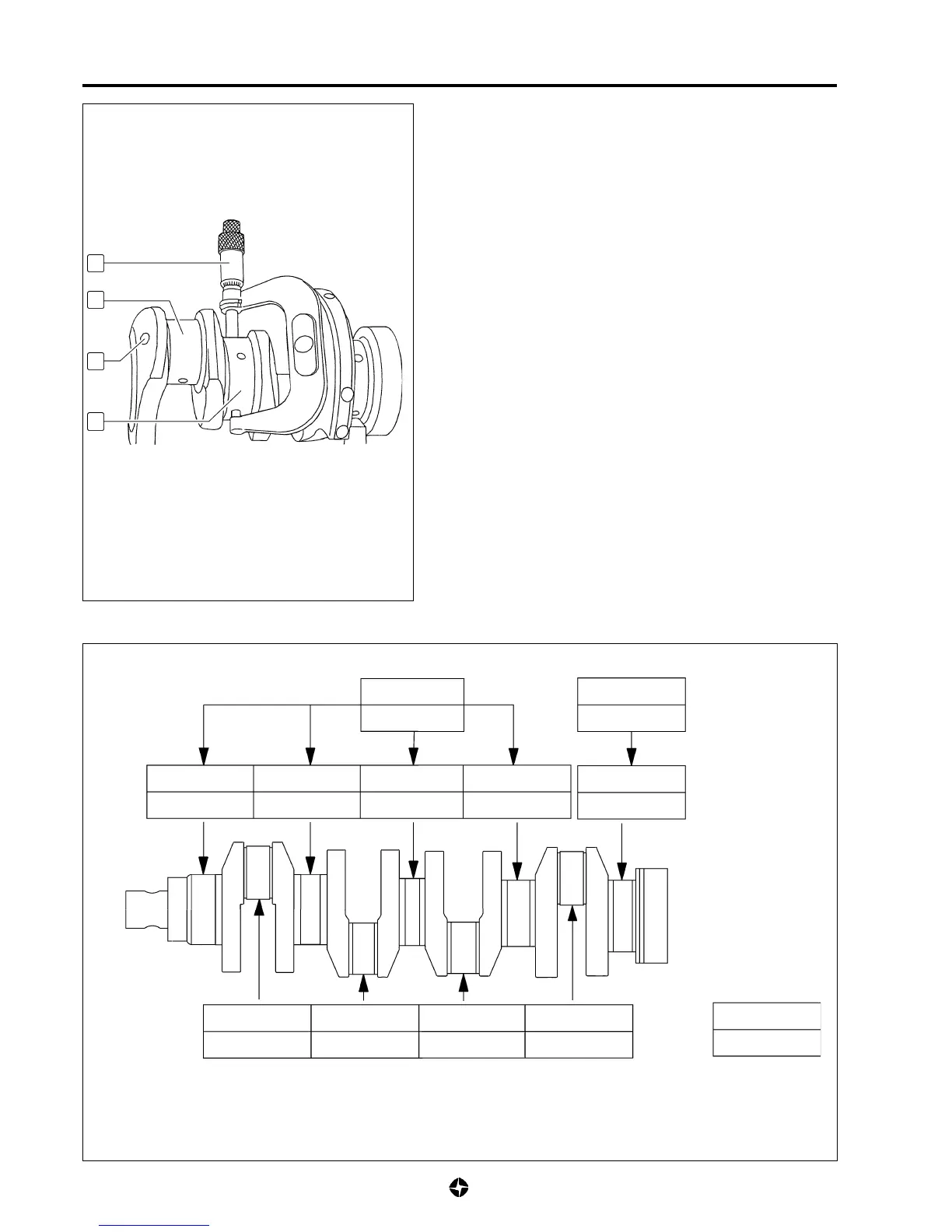

NOTE:

It is necessary to annotate the results of measurements

in a table as the one herewith to find out the oversize

to apply.

MINIMUM Ø

MAXIMUM Ø

MINIMUM Ø

MAXIMUM Ø

NOMINAL

VALUE

80,182

80,208

NOMINAL

VALUE

86,182

86,208

NOMINAL

VALUE

56,515

56,538

TABLE TO ANNOTATE THE MEASUREMENTS OBTAINED ON THE JOURNAL OF MAIN BEARING

AND CONNECTING ROD

Loading...

Loading...