ENGINE REPAIR 6A-97

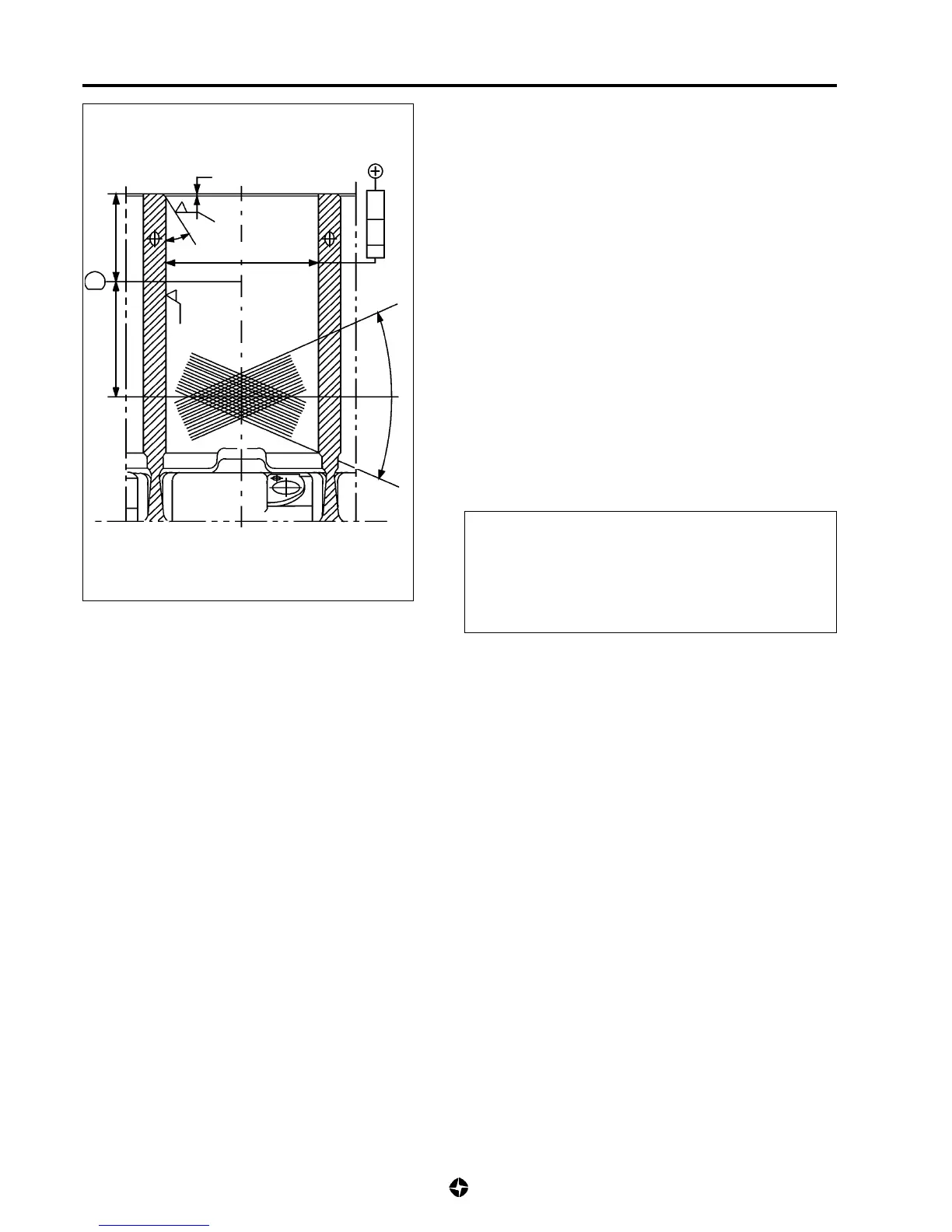

Cylinders surface finishing

1) Once the sheatings have been placed or oversize rectified,

proceed to final mechanical rectifying according to the stated

data and at the accompanying drawing.

Ø 1= Standard: 94,402 ÷ 94,432 mm

Ø 2= Oversize: 94,802 ÷ 94,832 mm

A-B= axle longitudinal and transversal

* Roughness parameters of surface.

R1= 4 ÷ 10 µm.

Rz= 3 ÷ 8 µm.

Ra= 0,3 ÷ 0,6 µm.

W1 < 2 µm.

Surface porosities allowed with milled cylinder.

ZONE B1= Greatest mechanical effort zone of the contact

piston rings/body ; intermitent n° 2 porousities allowed máx

0,5x0,5 (©100%)

ZONE B2= Surface affected by piston rings rubbings ; no

adjoining n° 2 porousities máx 1 x0,8 (©100%)

CAUTION:

After carrying out oversize mechanizing or cylinders

block sheating dismantle mechanization caps and

clean thoroughly the block using pressurized fluid

cleaner, compressed air and cylindrical sweeeping

brushes.

0,5

30°

00

B2=80

B1=50

*

==

0,08 A-B

45° ÷ 50°

^

Ø 1

Ø 2

Loading...

Loading...