The gray areas in the above graph show where A.710 and A.720 alarms

occur.

Refer to the relevant manual given below for a diagram that shows the relationships

between the Servomotor heat dissipation conditions (heat sink size, surrounding air tem-

perature, and derating). You can protect the Servomotor from overloads more effectively

by setting this derating value in Pn52C.

Name Manual number

Σ-7-Series Rotary Servomotor Product Manual SIEP S800001 36

Σ-7-Series Linear Servomotor Product Manual SIEP S800001 37

Σ-7-Series Direct Drive Servomotor Product Manual SIEP S800001 38

6.15 Setting Unit Systems

6.15.1 Overview

You can set the SERVOPACK reference units with PROFINET communications. You can

set the following three reference units with PROFINET communications.

n Position reference unit

n Speed reference unit

n Acceleration reference unit

The setting procedures are given below.

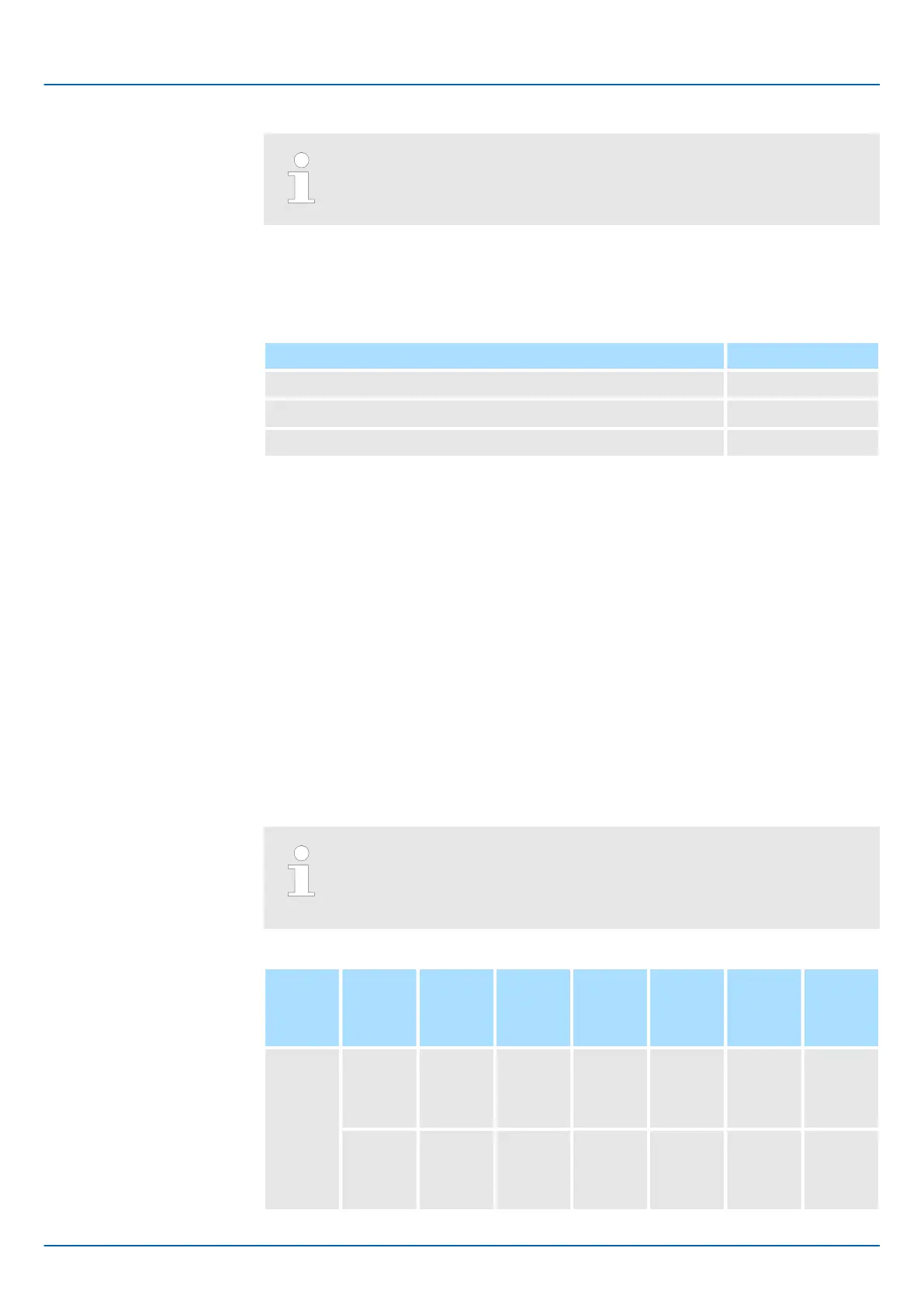

6.15.2 Setting the Position Reference Unit

Set the position reference unit in Position User Unit (2301h). The position reference unit

setting will be used for the electronic gear ratio setting.

– Set the position reference unit within the following range.

1/4,096 < Numerator/Denominator < 65,536

If the setting range is exceeded, an A.A20 alarm (Parameter Setting

Error) will occur.

Index Sub-

index

Name Data

Type

Access PDO

Map-

pings

Value Saving

to

EEPRO

M

2301h 1 Numer-

ator

UDINT RW No 1 £ Value

range £

2

31

-1(def

ault: 1)

Yes

2 Denomi-

nator

UDINT RW No 1 £ Value

range £

2

31

-1(def

ault: 1)

Yes

Sigma-7 Series SERVOPACKs

Basic Functions That Require Setting before Operation

Setting Unit Systems > Setting the Position Reference Unit

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 178

Loading...

Loading...