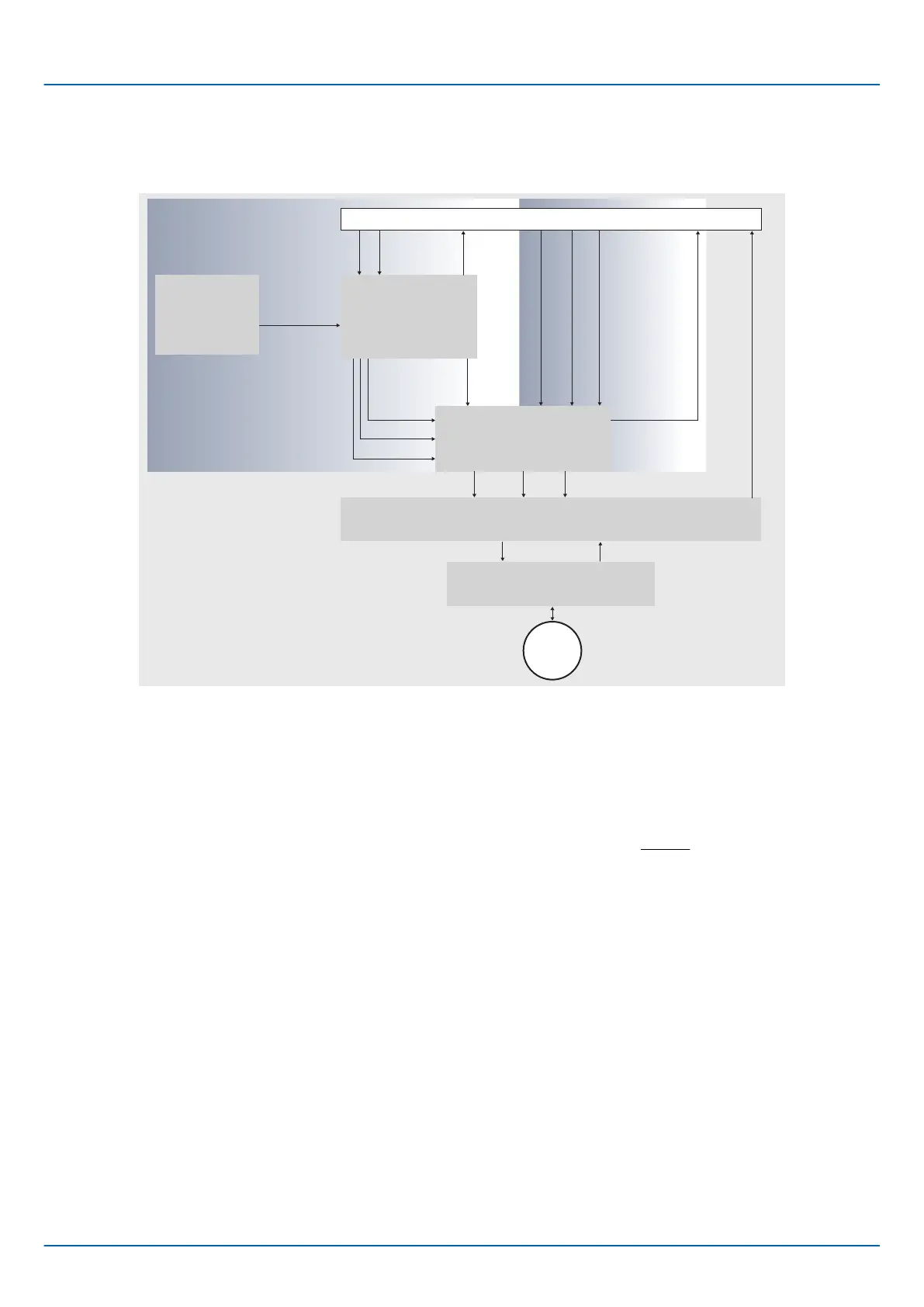

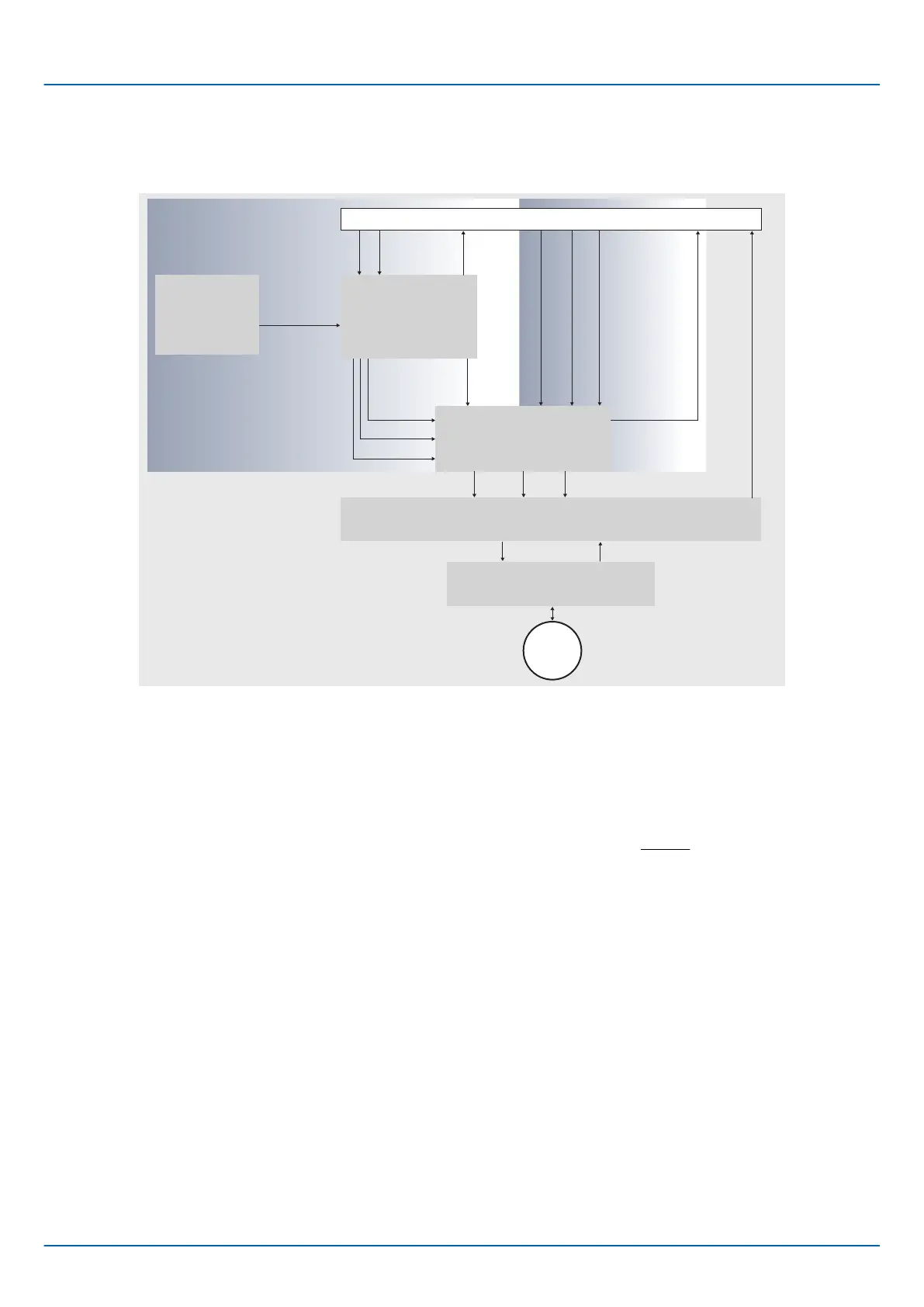

This SERVOPACK supports both submodes “Manual Data Input” (MDI) and “Program”.

DO IO Data

Program

interpreter

SATZANW

(task select)

XIST_A

Program

motion record

STW1

(start, stop)

MDI_TARPOS

MDI_VELOCITY

MDI_ACC, MDI_DEC

Program control interface

Path interpolation

Motion command interface

Submode switch

MDI interface

Position and speed closed loop control

Position setpoint interface

Program

storage

Motion programs

AKTSATZ

TARPOS

ACC, DEC

Submode control

(SATZANW.15)

M

TARPOS

ACC DEC

Submode status

(AKTSATZ.15)

VELOCITY

VELOCITY

Program submode MDI submode

Fig. 364: Program Submode and MDI Submode

14.3.2 MDI Submode

The motion controller for Manual Data Input (MDI) submode comprises in addition to the

Program submode components also a submode switch which enables the direct access

to the motion command interface from the DO IO Data without using the program inter-

preter. This results in the advantage of immediate control of the motion command inter-

face by the controller via DO IO DATA.

Changeover from the program execution to the MDI interface and vice versa is controlled

by Bit 15 of Traversing Block Selection (SATZANW) (2532h):

n Bit 15 = 1

Activation of the MDI submode. If there is a program still running (extended state

machine not in the Basic State), the positioning interface will change to MDI Submode

only after the program ends or is terminated (STW1 bit 4).

n Bit 15 = 0

Deactivation of the MDI submode. If there is a MDI motion command still executed

the path interpolation shall stop and the MDI motion command shall be rejected.

If MDI submode is active, the input for the motion command interface of the path interpo-

lator will be taken out of the signals Target Position, Acceleration, Deceleration and

Velocity. These values get valid as input for the calculation of a new path from the actual

axis position to the new target position with the rising edge of STW1 bit 6. Controlling of

the motion process is done by the dedicated bits of STW1 out of the DO IO Data.

PROFIdrive Position

Submodes “MDI” and

“Program”

Activation / Deactivation

of the MDI submode

Sigma-7 Series SERVOPACKs

PROFIdrive Drive Profile

PROFIdrive Position Mode > MDI Submode

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 504

Loading...

Loading...