9.4.3 Torque Limit Settings

You can limit the torque that is output by the Servomotor based on calculations of the

torque required for machine operation. You can use torque limits to reduce the amount of

shock applied to the machine when problems occur, such as collisions or interference. If

the torque limit is lower than the torque that is required for operation, overshooting or

vibration may occur. Refer to the following section for details.

Ä

Chap. 7.8 ‘Selecting Torque Limits’ page 221

9.4.4 Setting the Position Deviation Overflow Alarm Level

The position deviation overflow alarm is a protective function that is enabled when the

SERVOPACK is used in position control.

If the alarm level is set to a suitable value, the SERVOPACK will detect excessive posi-

tion deviation and will stop the Servomotor if the Servomotor operation does not agree

with the reference.

The position deviation is the difference between the position reference value and the

actual position.

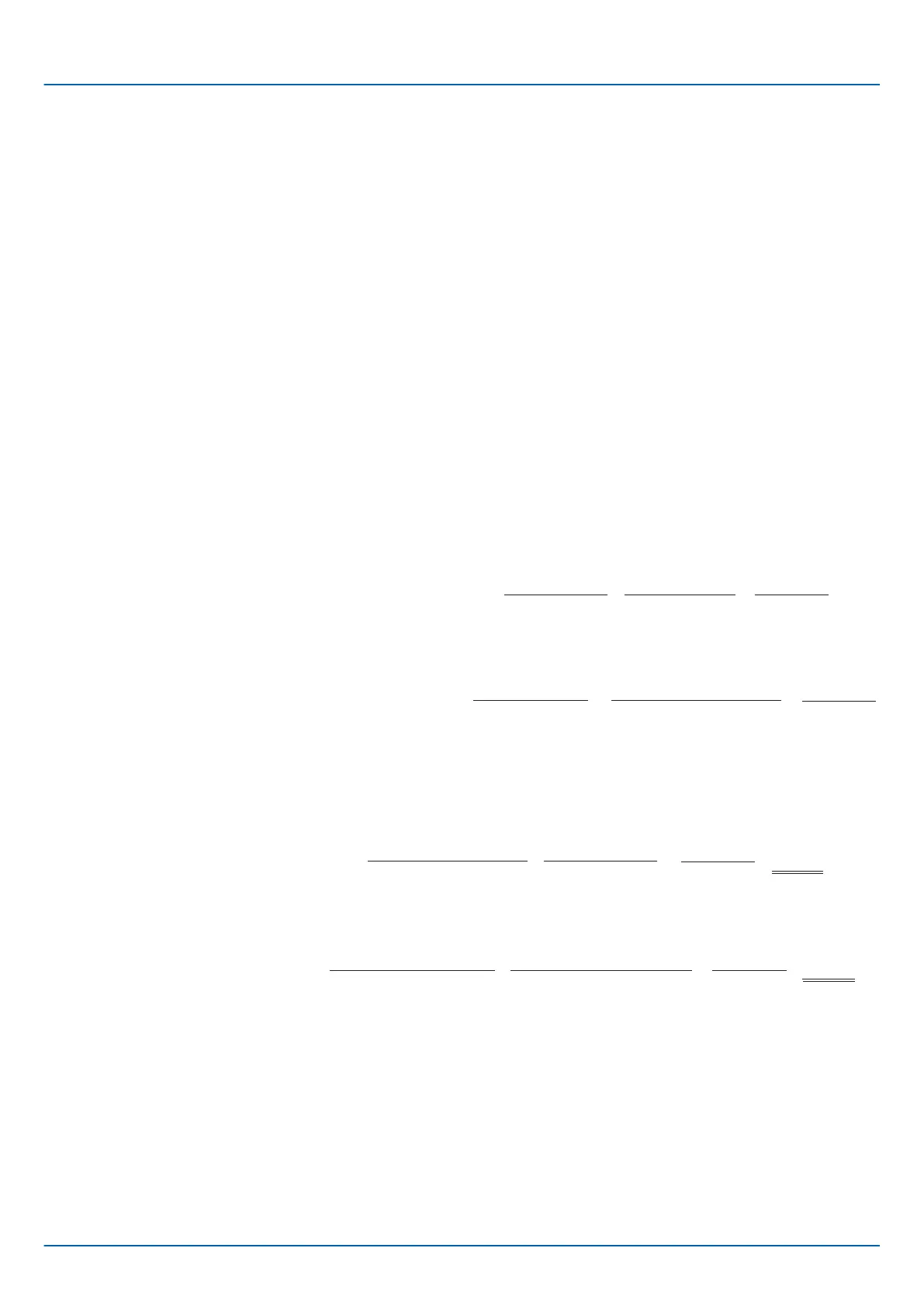

You can calculate the position deviation from the position loop gain (Pn102) and the

motor speed with the following formula.

´

60

Pn102 [0.1/s]/10

*2, *3

´

Denominator

*1

Numerator

Encoder resolution

Motor speed [min

-1

]

Position deviation [reference units] =

Fig. 219: Position Deviation - Formula - Rotary Servomotors

Pn102 [0.1/s]/10

*2, *3

´ ´

Denominator

Numerator

Linear encoder pitch [mm]/1,000

ResolutionMotor speed [mm/s]

Position deviation [reference units] =

Fig. 220: Position Deviation - Formula - Linear Servomotors

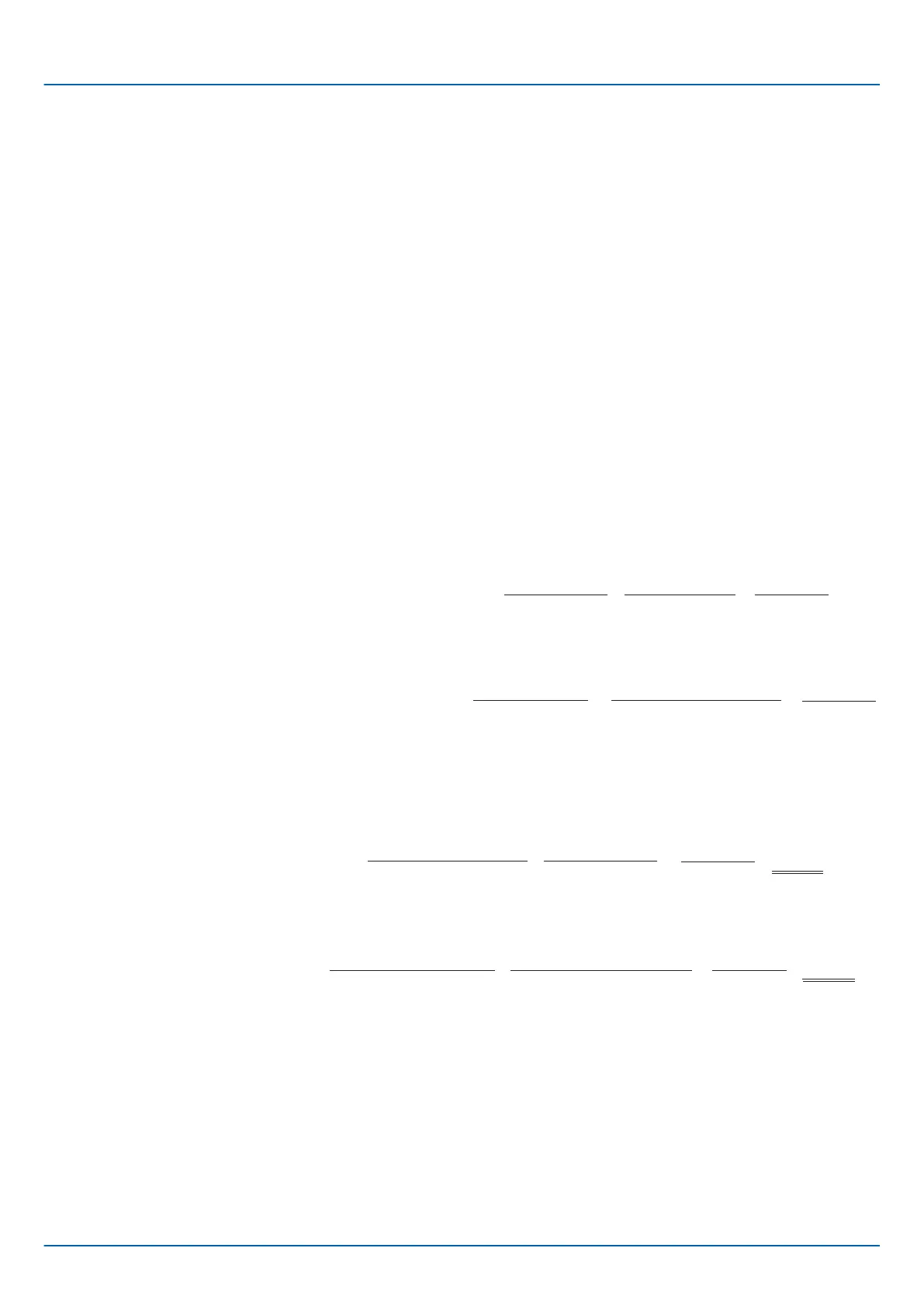

Position Deviation Overflow Alarm Level (Pn520) [setting unit: reference units]

Pn520 > ´ ´

60

Pn102 [0.1/s]/10

*2, *3

´

Denominator

*1

Numerator

(1.2 to 2)

*4

Encoder resolutionMaximum motor speed [min-1]

Fig. 221: Position Deviation Overflow Alarm Level - Formula - Rotary Servomotors

Pn520 >

Pn102 [0.1/s]/10

*2, *3

´ ´

Denominator

*1

Numerator

(1.2 to 2)

*4

Linear encoder pitch [µm]/1,000

Resolution

Maximum motor speed [mm/s]

´

Fig. 222: Position Deviation Overflow Alarm Level - Formula - Linear Servomotors

*1. Refer to the following section for details.

Ä

Chap. 6.15 ‘Setting Unit Systems’ page 178

*2. When model following control (Pn140 = n.1) is enabled, use the setting of

Pn141 (Model Following Control Gain) instead of the setting of Pn102 (Position Loop

Gain).

*3. To check the setting of Pn102 on the Digital Operator, change the parameter display

setting to display all parameters (Pn00B = n.1).

Rotary Servomotors

Linear Servomotors

Rotary Servomotors

Linear Servomotors

Sigma-7 Series SERVOPACKs

Tuning

Precautions to Ensure Safe Tuning > Setting the Position Deviation Overflow Alarm Level

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 300

Loading...

Loading...