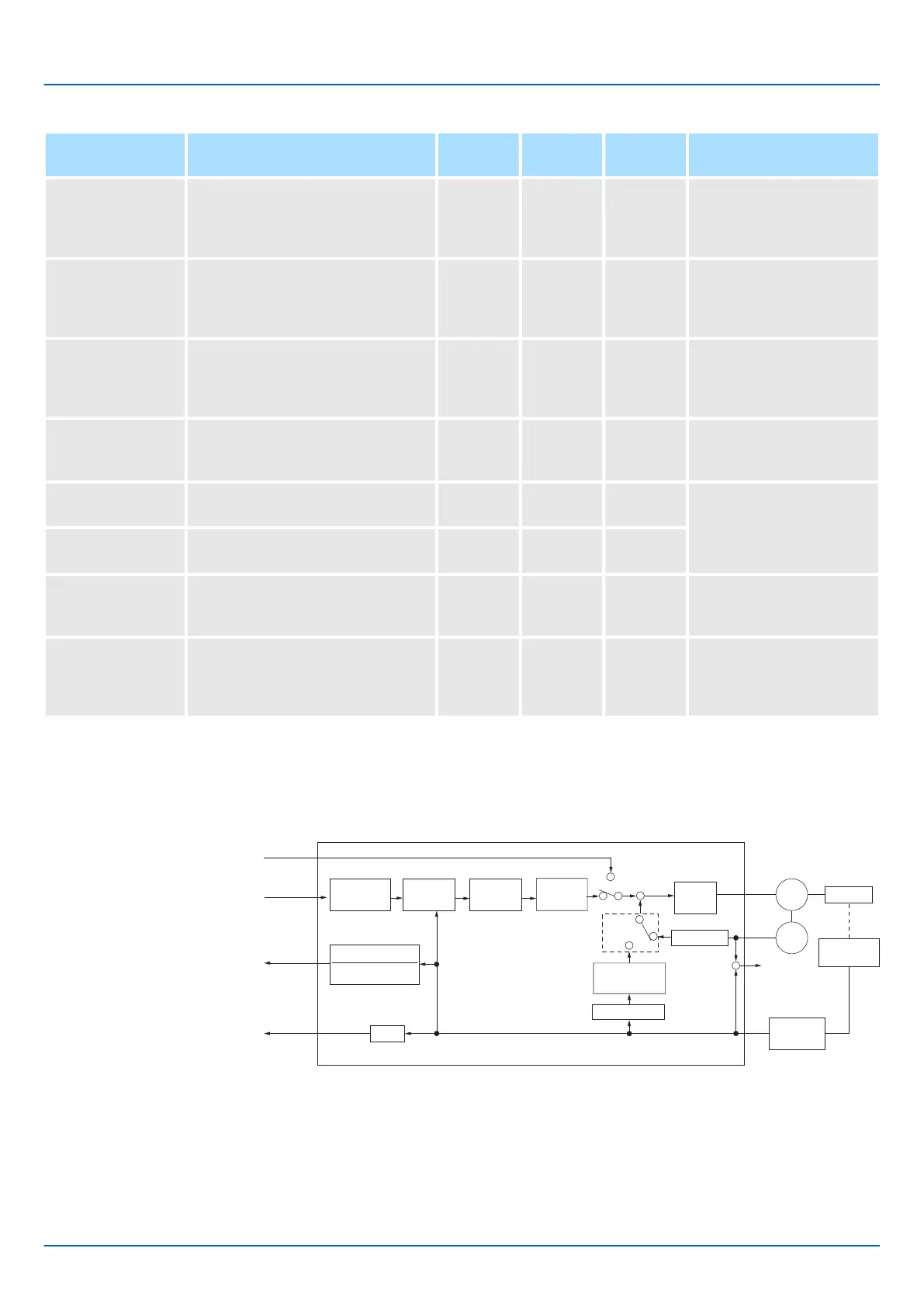

Parameter and

Object to Set

Setting Position

Control

Speed

Control

Torque

Control

Reference

Pn20A Number of external scale pitches

ü ü ü

Ä

Chap. 11.4.4 ‘Setting

the Number of External

Encoder Scale Pitches’

page 459

Pn281 Encoder divided pulse output sig-

nals (PAO, PBO, and PCO) from

the SERVOPACK

ü ü ü

Ä

Chap. 11.4.5 ‘Setting

the PAO, PBO, and PCO

(Encoder Divided Pulse

Output) Signals’ page 460

– External absolute encoder data

reception sequence

ü ü ü

Ä

Chap. 7.10.5 ‘Reading

the Position Data from the

Absolute Linear Encoder’

page 241

Position User Unit

(2301h)

Electronic gear ratio

ü

− −

Ä

Chap. 6.15.2 ‘Setting

the Position Reference

Unit’ page 178

Pn51B Excessive deviation level between

Servomotor and load positions

ü

− −

Ä

Chap. 11.4.8 ‘Alarm

Detection Settings’

page 461

Pn52A Multiplier for one fully-closed rota-

tion

ü

− −

Pn006/ Pn007 Analog monitor signal

ü ü ü

Ä

Chap. 11.4.9 ‘Analog

Monitor Signal Settings’

page 462

Pn22A = n.X

Speed feedback method during

fullyclosed loop control

ü

− −

Ä

Chap. 11.4.10 ‘Setting

to Use an External

Encoder for Speed Feed-

back’ page 463

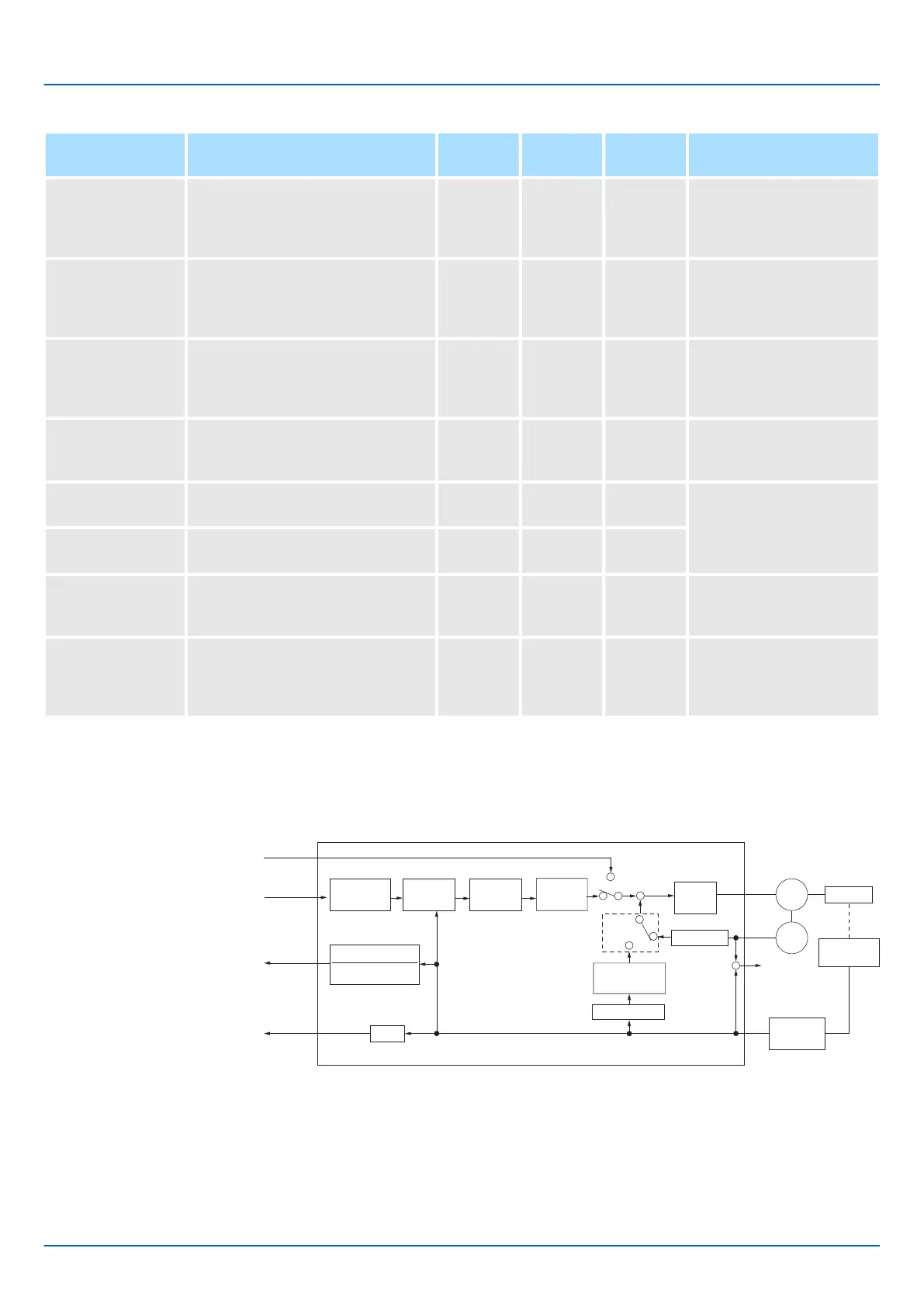

11.4.2 Control Block Diagram for Fully-Closed Loop Control

The control block diagram for fully-closed loop control is provided below.

-

ENC

*

A.d10

Pn22A

Position unit

multiplier

+

Pn281

1

Position unit multiplier

Position

deviation

Motor

SERVOPACK

Deviation

counter

Position

control loop

Unit conversion

Pn20A

Speed

feedback

Speed

loop

Speed conversion

Alarm

detection

Unit conversion

Pn20A

Divider

Speed conversion

External

encoder

Serial

conversion

Machine

Speed

reference

Position

reference

Encoder

divided

pulse

output

Fig. 335: Control Block Diagram for Fully-Closed Loop Control

* The connected device depends on the type of external encoder.

Sigma-7 Series SERVOPACKs

Fully-Closed Loop Control

Parameter and Object Settings for Fully-closed Loop Control > Control Block Diagram for Fully-Closed Loop Control

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 457

Loading...

Loading...