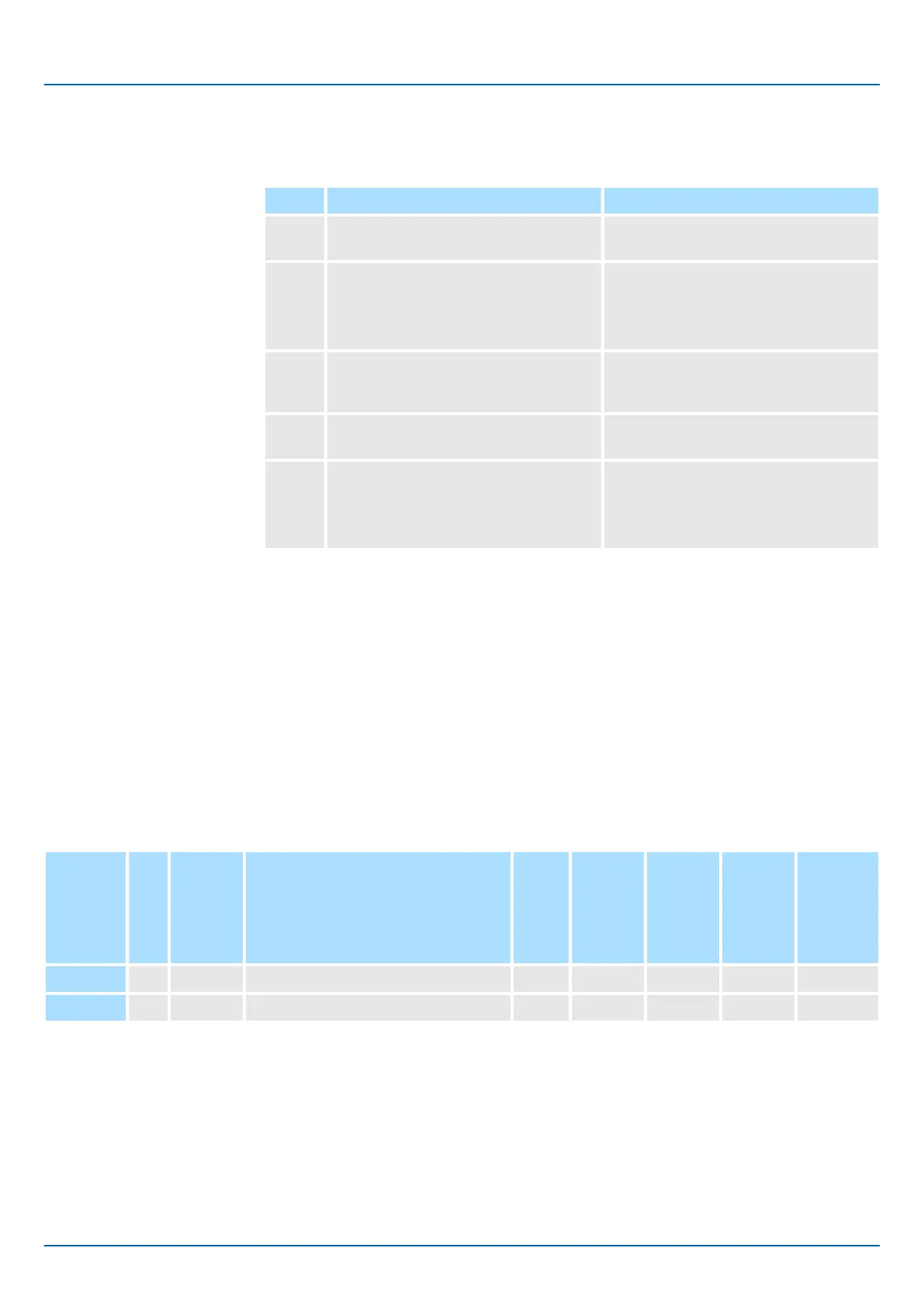

The basic setting procedure for the related parameters is given in the following table.

Step Description Parameter Setting

1 Set the speed feedback method to

use during fully-closed loop control.

Fully-closed Control Selections

(Pn22A)

2 Set the motor rotation direction. Rotation Direction Selection (Pn000 =

n.X)

External Encoder Usage (Pn002 =

n.X)

3 Set the number of pitches (cycles) of

the sine wave for the external

encoder.

Number of External Scale Pitches

(Pn20A)

4 Set the position reference unit (elec-

tronic gear).

Position User Unit (2301h)

5 Set the alarm detection level for the

external encoder.

Motor-Load Position Deviation Over-

flow Detection Level (Pn51B)

Multiplier per Fully-closed Rotation

(Pn52A)

14.11 Get/Set SERVOPACK Parameter Functionality

Internal SERVOPACK parameters (Pn)

Ä

Chap. 17.2.2 ‘List of Parameters’

page 661 can be read or written with PROFINET Communications.

Reading internal Servo parameter. In order to read SERVOPACK parameter do the fol-

lowing:

n Write parameter number to object "Get Parameter - Parameter Identify" (2100h)

n Read the value from object "Get Parameter - Parameter Value" (2101h)

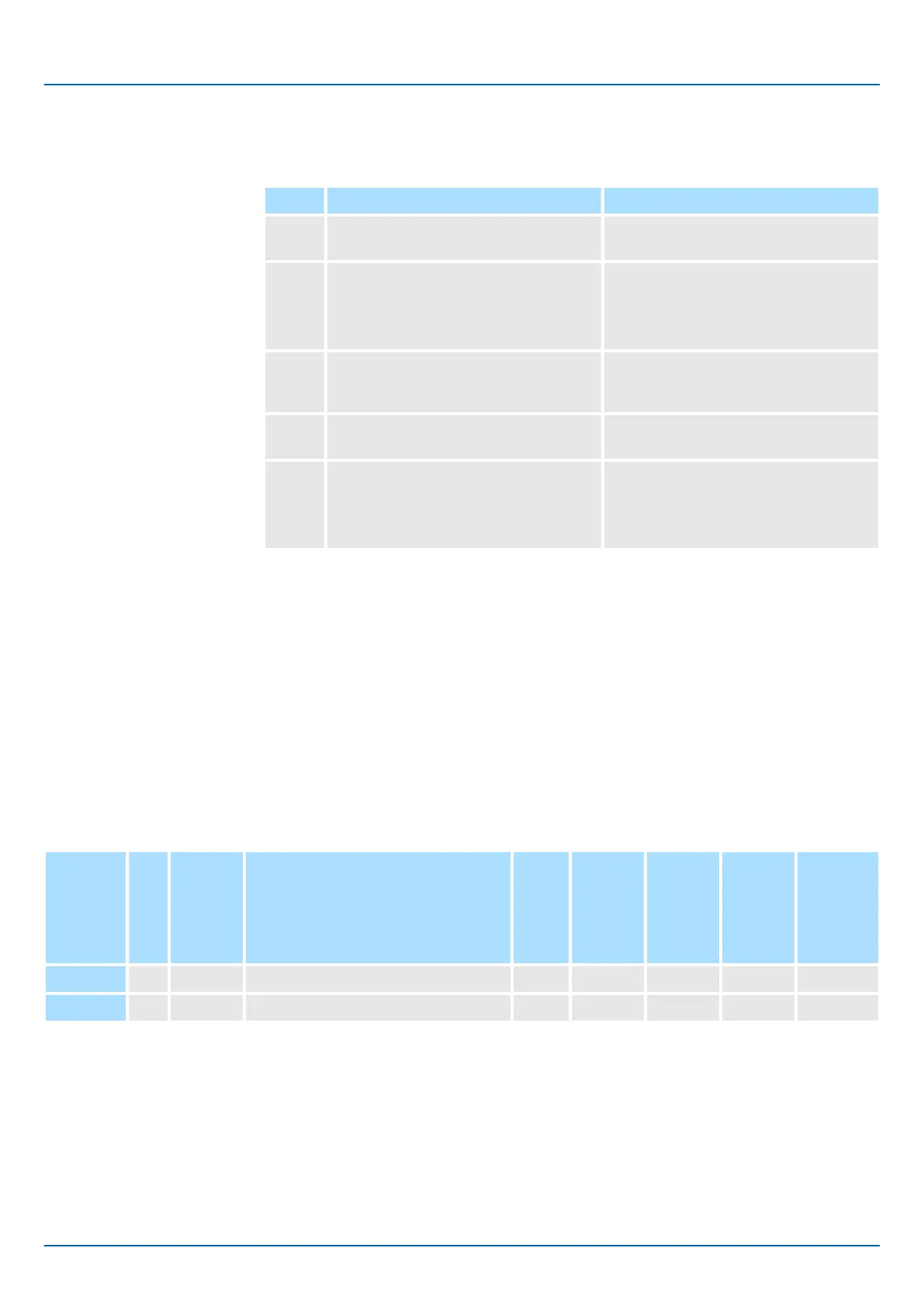

Index

(hex)

Sub

Pn No.

Name

Access

PDO Mapping

Default value

Units

Type

2100h 0 Get Parameter - Parameter Identify RW No FFFFh - UINT

2101h 0 Get Parameter - Parameter Value RO No 0 - DINT

Setting / Writing internal Servo parameter. In order to set Servo parameter do the fol-

lowing:

n Write parameter number to object "Set Parameter - Parameter Identify" (2102h)

n Write the value into object "Set Parameter - Parameter Value" (2103h)

Setting Parameters

Get SERVOPACK Param-

eter

Related Objects

Set SERVOPACK Param-

eter

Sigma-7 Series SERVOPACKs

PROFIdrive Drive Profile

Get/Set SERVOPACK Parameter Functionality

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 520

Loading...

Loading...