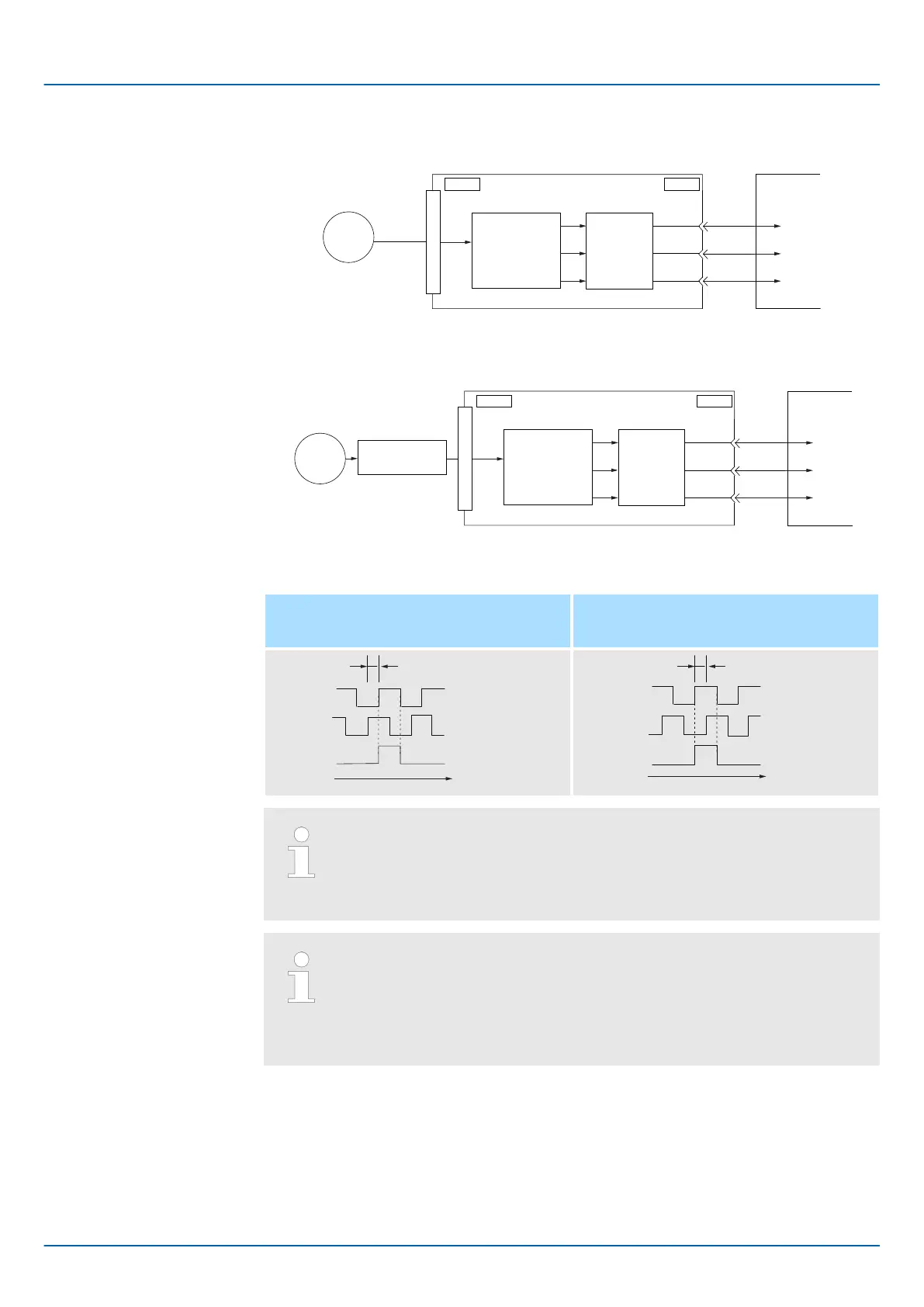

n Rotary Servomotor

ENC

CN1CN2

PAO

PBO

PCO

(Pn212)

SERVOPACK

Host controller

Serial

data

Conversion of

serial data to

pulses

Dividing

circuit

Fig. 153: Encoder Signal Output - Rotary Servomotor

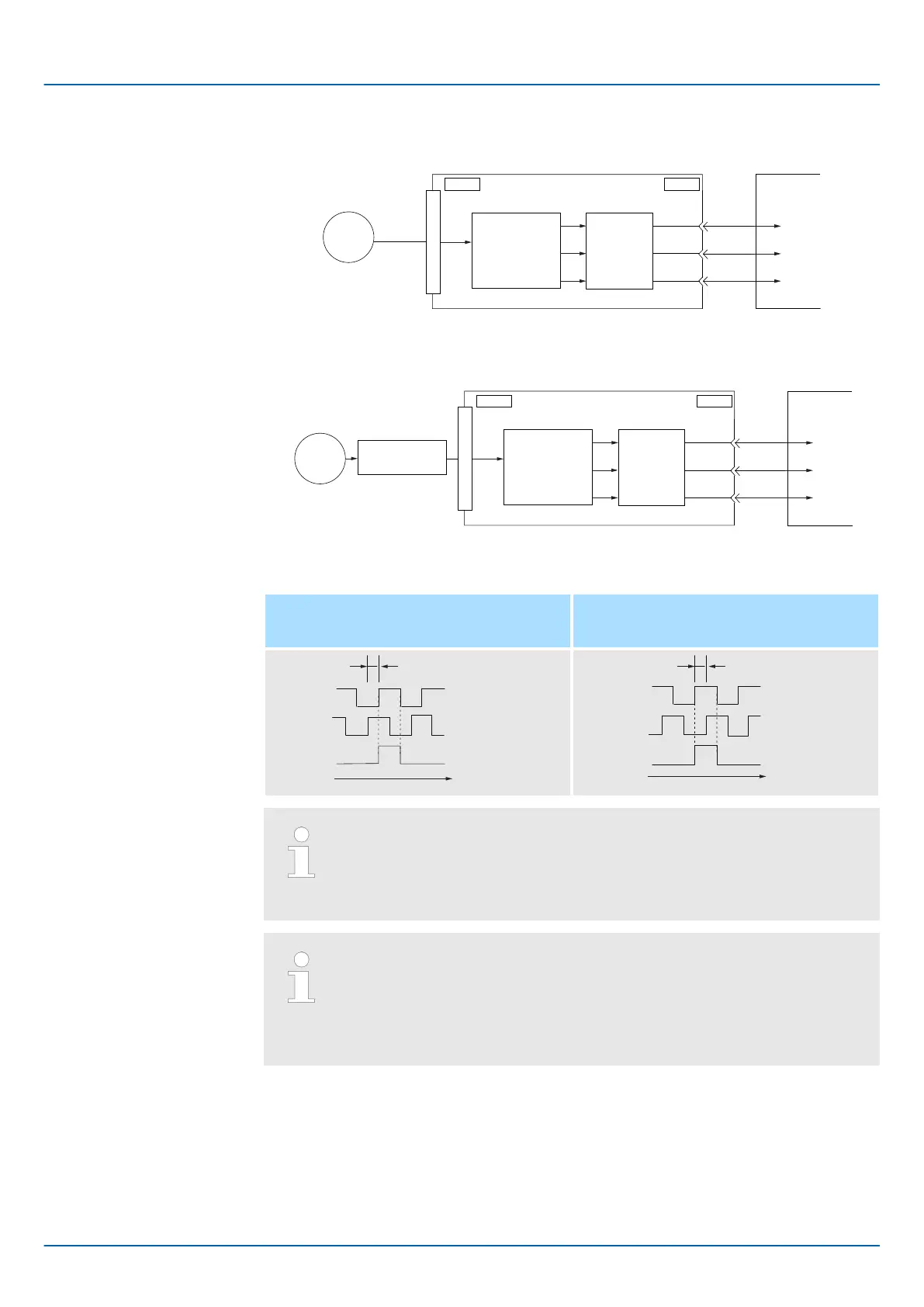

n Linear Servomotors

ENC

CN1

CN2

PAO

PBO

PCO

(Pn281)

Linear

encoder

Serial data

Serial

Converter Unit

SERVOPACK

Conversion of

serial data to

pulses

Dividing

circuit

Host controller

Fig. 154: Encoder Signal Output - Linear Servomotor

Forward rotation or movement

(phase B leads by 90°)

Reverse rotation or movement

(phase A leads by 90°)

90°

t

Phase A

Phase B

Phase C

90°

t

Phase C

Phase B

Phase A

The pulse width of the origin within one encoder rotation depends on the

setting of number of encoder output pulses (Pn212) or the encoder output

resolution (Pn281). It is the same as the width of phase A. Even for

reverse operation (Pn000 = n.

1), the output phase form is the same

as shown above.

If you use the SERVOPACK’s phase-C pulse output for an origin return,

rotate the Servomotor two or more rotations before you start an origin

return. If the Servomotor cannot be rotated two or more times, perform an

origin return operation at a motor speed of 600 min

-1

or lower. If the motor

speed is higher than 600 min

-1

, the phase-C pulse may not be output cor-

rectly.

The following precautions apply to the encoder output pulses when an external linear

encoder is used.

Relation between Renishaw PLC Incremental Linear Encoders and Encoder Output

Pulse Signal from the SERVOPACK when using a RGS20 Scale and RGH22B

Sensor Head

Output Phase Forms

Linear Encoder Applica-

tion Precautions

Sigma-7 Series SERVOPACKs

Application Functions

Encoder Divided Pulse Output > Encoder Divided Pulse Output Signals

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 214

Loading...

Loading...