FRONT AND REAR PROPELLER SHAFTS 4C-5

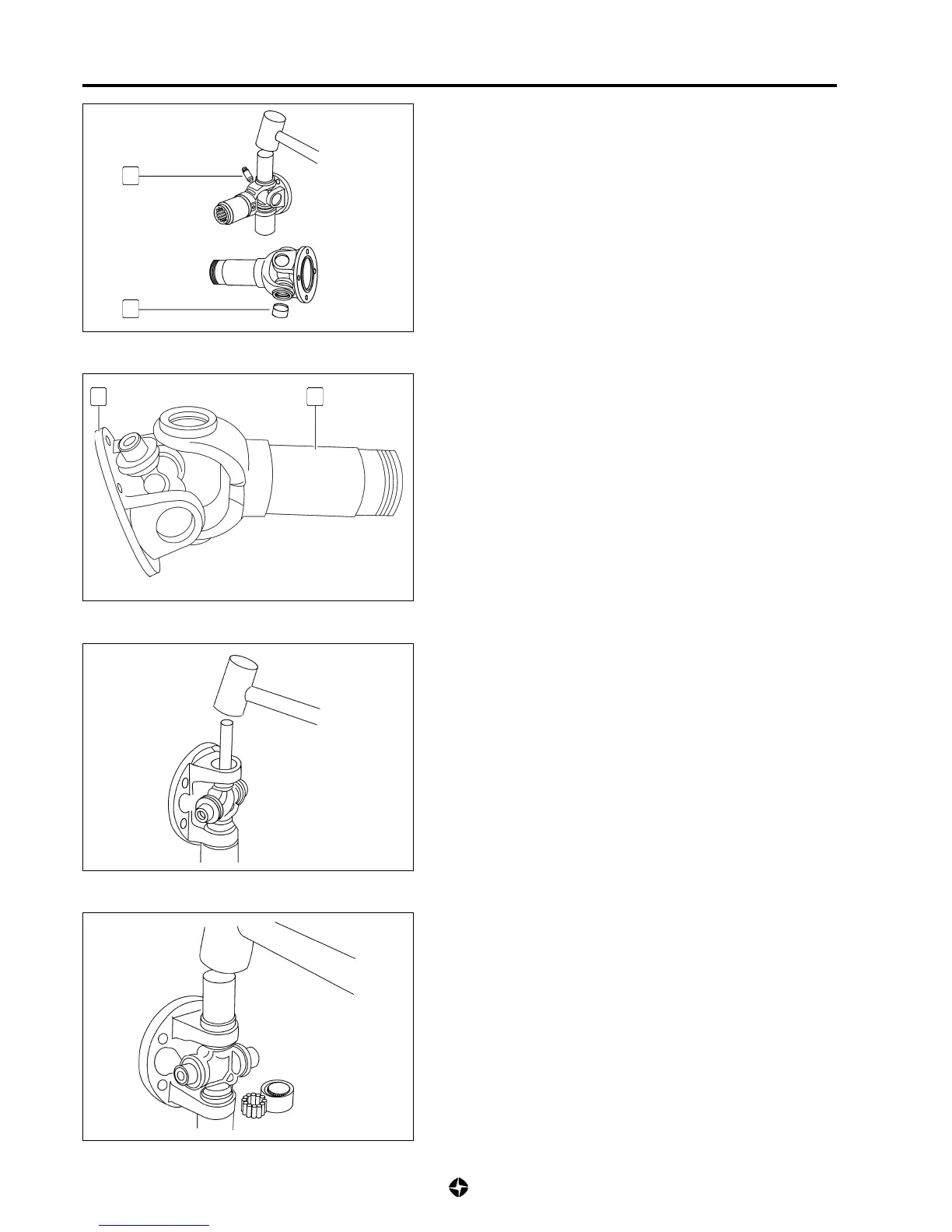

10) Using a tube with internal diameter greater than the one of

the bearings, and a soft pushing rod with external diameter

slightly less than that of the bearings, remove bearing at

one of the sides as indicated in the figure.

11) Extracted bearing (5) will be lodged into the tube.

12) Remove opposite bearing in the same way than the first

one, pushing away the crosshead through the hole having

been left by the extracted bearing.

13) Remove oil filter (6), if necessary.

2

3

6

5

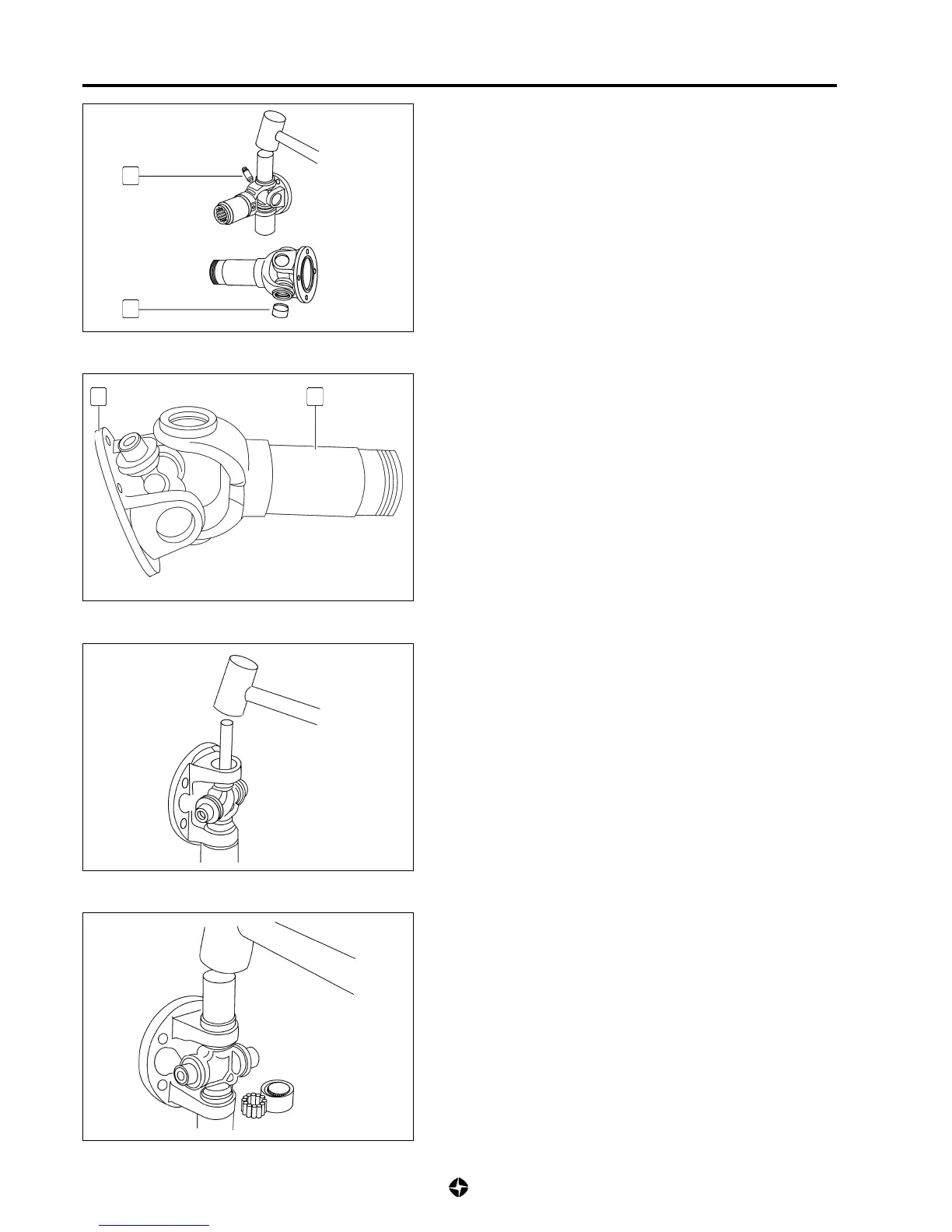

15) Remove the remaining two bearings in the same way than

previous ones, been thus able to separate flange from the

crosshead.

16) Place needles in the bearings paths and apply a small

amount of grease to keep them in place.

17) Once the needles have been placed, fill bearings till half

with recommended grease.

18) Install bearing on its lodging at the fork.

19) Mount a new crosshead in the bearing and introduce it till

the top.

20) Install opposite bearing in same way and fix it with a circlip,

ensuring they are perfectly lodged in the fork channellings.

21) Install the other two bearings in the way indicated previously.

NOTE:

• Bearings must be mounted with sliding pressure.

• Avoid bearings fit into casings in an irregular fashion,

inclined or sidewise.

14) Separate the grooved shaft (2) from the crosshead and the

flange (3).

Loading...

Loading...