6A-64 ENGINE REPAIR

DISMANTLING AND ASSEMBLY OF THE SERVO

STEERING HYDRAULIC PUMP

CAUTION:

Before starting dismantling clean thoroughly

components to be dismantled and around them.

Dismantling

1) Dismantle water radiator and air radiator (intercooler) (see

6B-8).

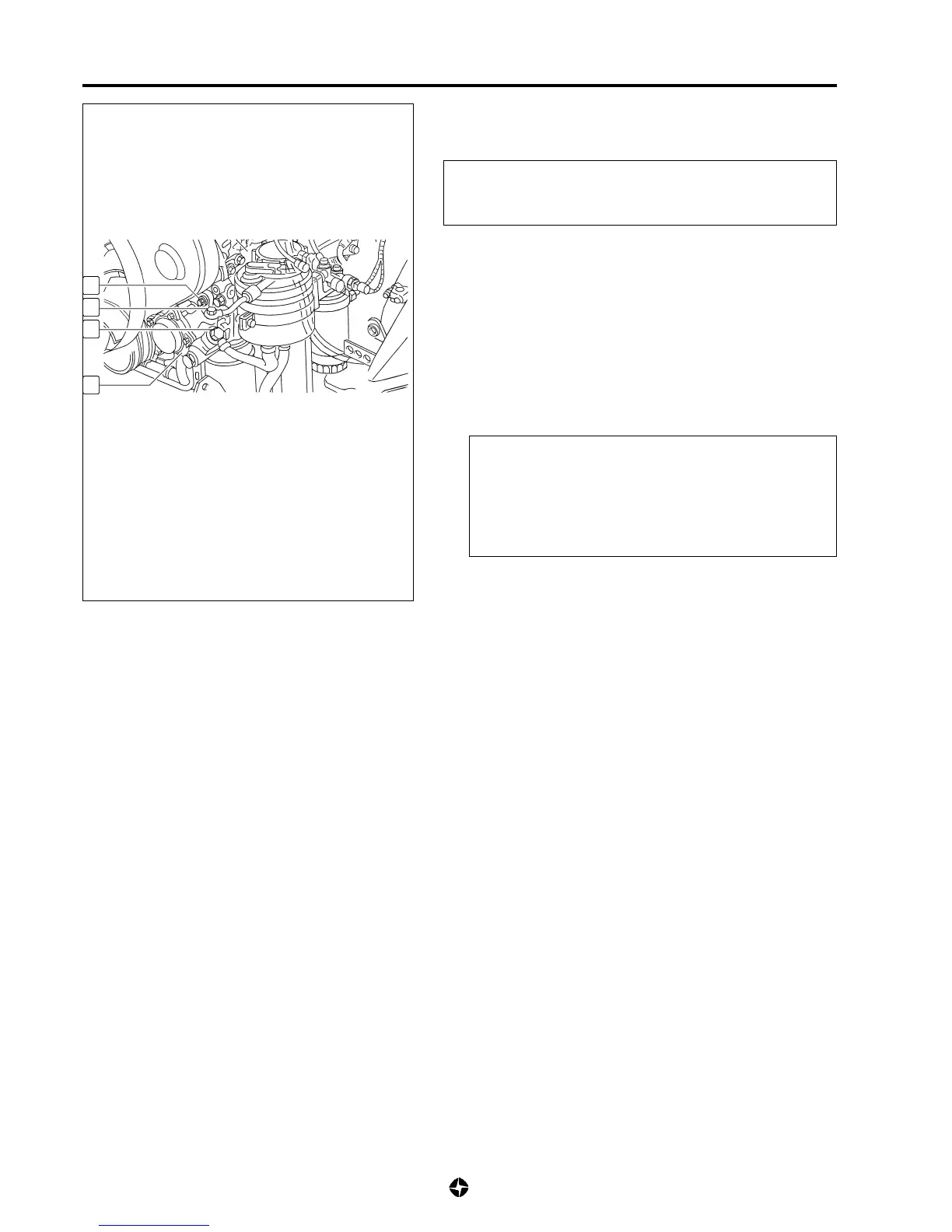

2) Disconnect inlet linkage (3) of hydraulic oil to pump and

pour the content of the tank in an adequate container.

3) Disconnect outlet linkage (2) of pressurized oil at pump.

4) Dismantle nuts (1) fixing hydraulic pump (4) to body of the

auxiliary organs group.

5) Take away hydraulic pump (4).

CAUTION:

Plug with appropriated caps air, water and

hydraulic circuits holes while they keep appearing

during dismantling because the entry of alien bodies

in the conductions could seriously damage the

component in question.

Assembly

NOTE:

Clean carefully touching contact areas of pumps, linkages

and lodgings in auxiliary organs group.

1) Proceed to assemble reversing the dismantling order paying

attention to the following tasks:

• Assemble the new impermeabilizing gaskets, washers and

pieces showing any damage.

• Continue assembly applying specified tightening torque's.

Tightening torque:

• Screw linkage at hydraulic pump oil outlet:

3 ÷ 4 Kg-m (30 ÷ 40 Nm)

• Screw linkage at hydraulic pump oil inlet:

3 ÷ 4 Kg-m (30 ÷ 40 Nm)

• Nuts fixing hydraulic pump:

3,5 Kg-m (35 Nm)

1

2

3

4

2) Proceed to fill and purge the hydraulic circuit of the servo

steering (see 0B-27).

Loading...

Loading...