6A-92 ENGINE REPAIR

CYLINDERS BLOCK REPAIR

Revision and measurement of cylinders block

Revision

1) Clean thoroughly cylinders block and check carefully there

are no cracks.

2) Verify caps of mechanization to see they are not oxidized

or present lack of impermeability.

NOTE:

If there are any anomalies substitute whatever is necessary.

3) Check that cylinders do not show signs of wear, scratches,

or excessive oval or conical shape.

Cylinders measurement

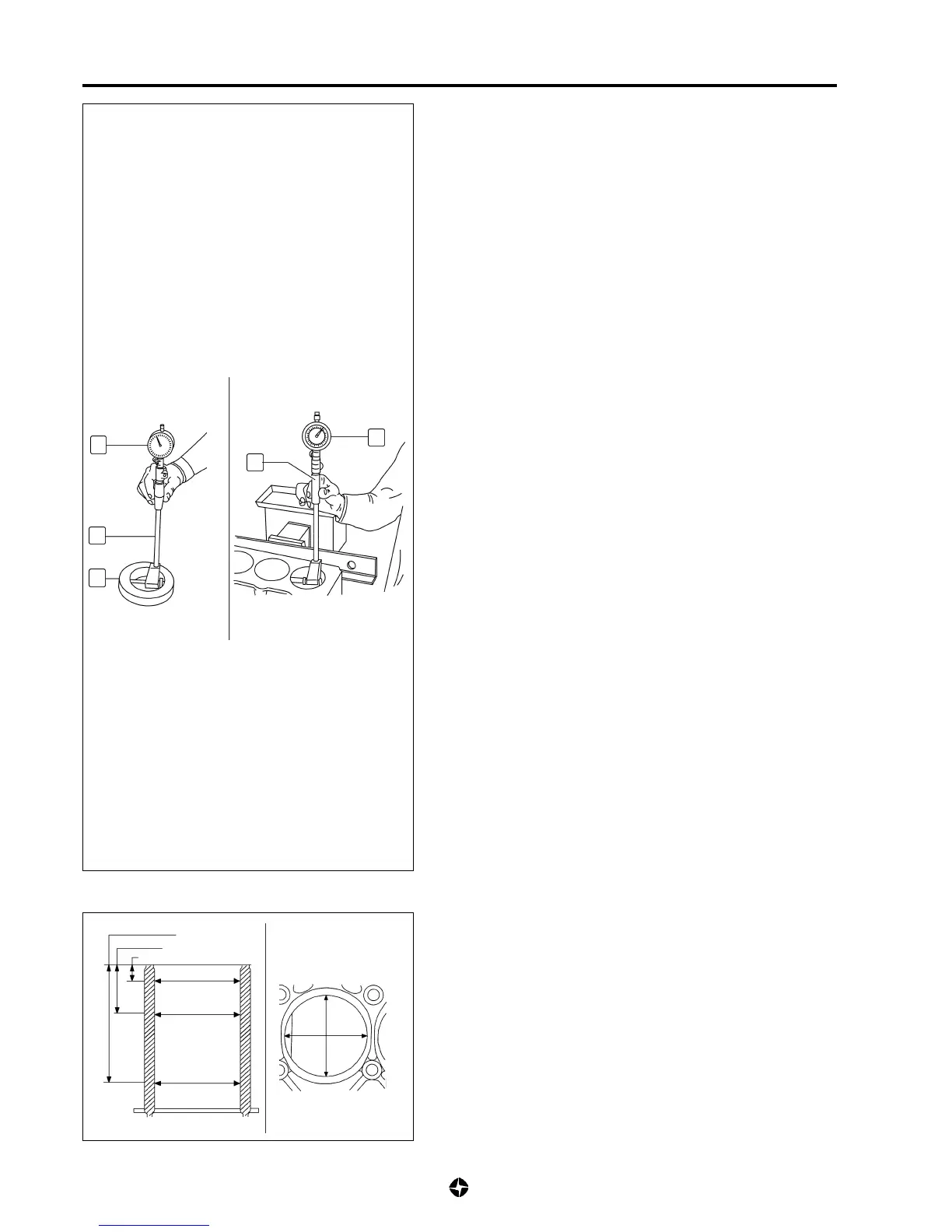

1) To control the level of wear, oval and conical shaping of

cylinders use a calliper for interiors (1) provided with

centesimal dial gauge (2) previously set to zero with ring

caliper (3).

NOTE:

The measurement of caliper (3) for setting to zero the

comparator, corresponds with the nominal

measurement of the cylinders diameter. If you do not

have this kind of caliper, use a micrometer for setting

to zero the comparator.

The micrometer must be adjusted to specified

measurement.

Micrometer measurement for adjusting to zero the

comparator: 94,402 mm

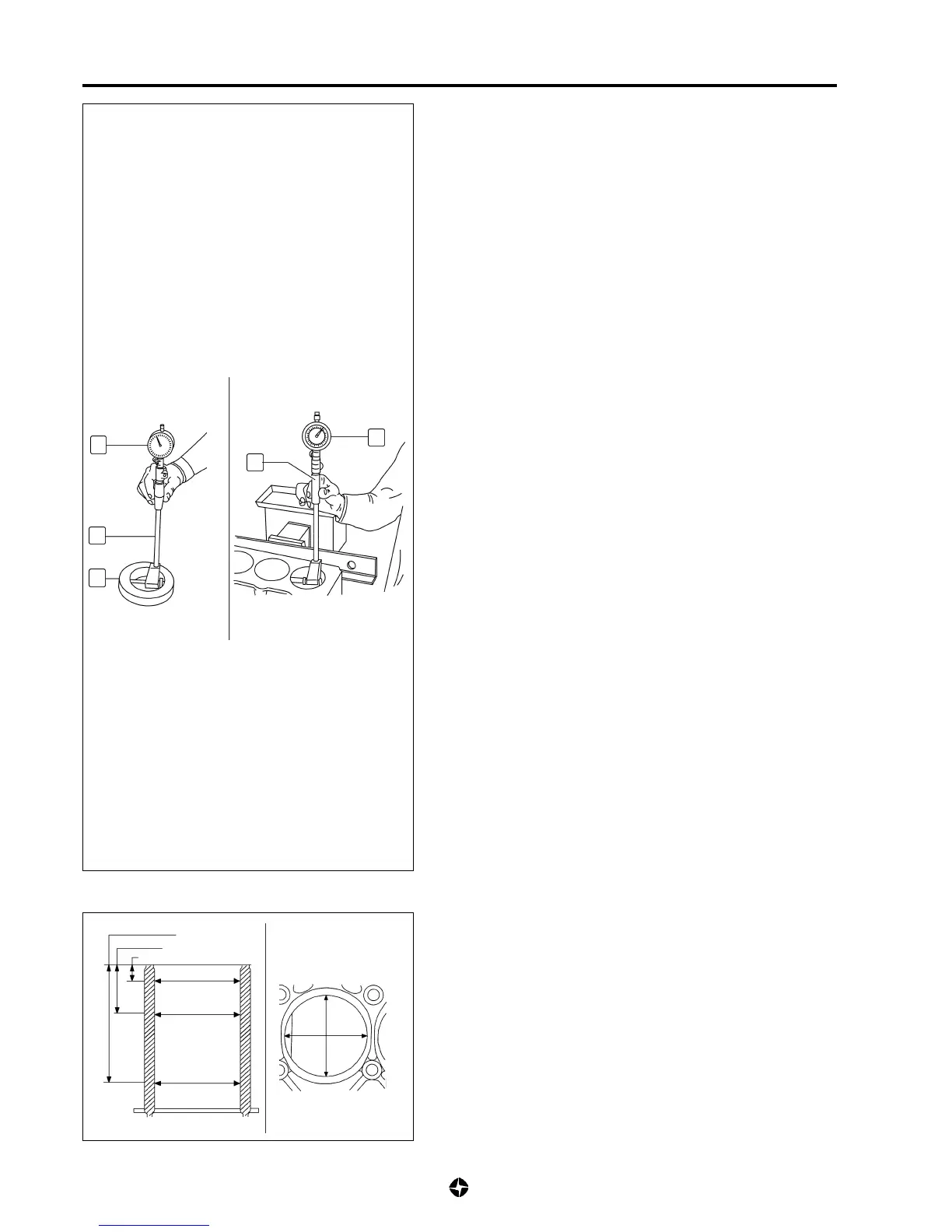

2) Carry out three measurements at three different heights of

the cylinder as shown and at two planes perpendicular one

to another. One plane is parallel to the longitudinal axle of

engine (A) and another perpendicular (B). On this later plane

and respect to the first measurement, maximum wear is

detected usually.

NOTE:

• If the readings taken on wear, oval and conical

eccentricities of cylinders are no greater than 0.4 mm

in respect of the nominal Ø of the cylinders rectify

cylinders accordingly .

2

1

3

1

2

B

A

142

50

10

1

st

mensuration

Ø

2

nd

mensuration

3

rd

mensuration

Loading...

Loading...