6A-94 ENGINE REPAIR

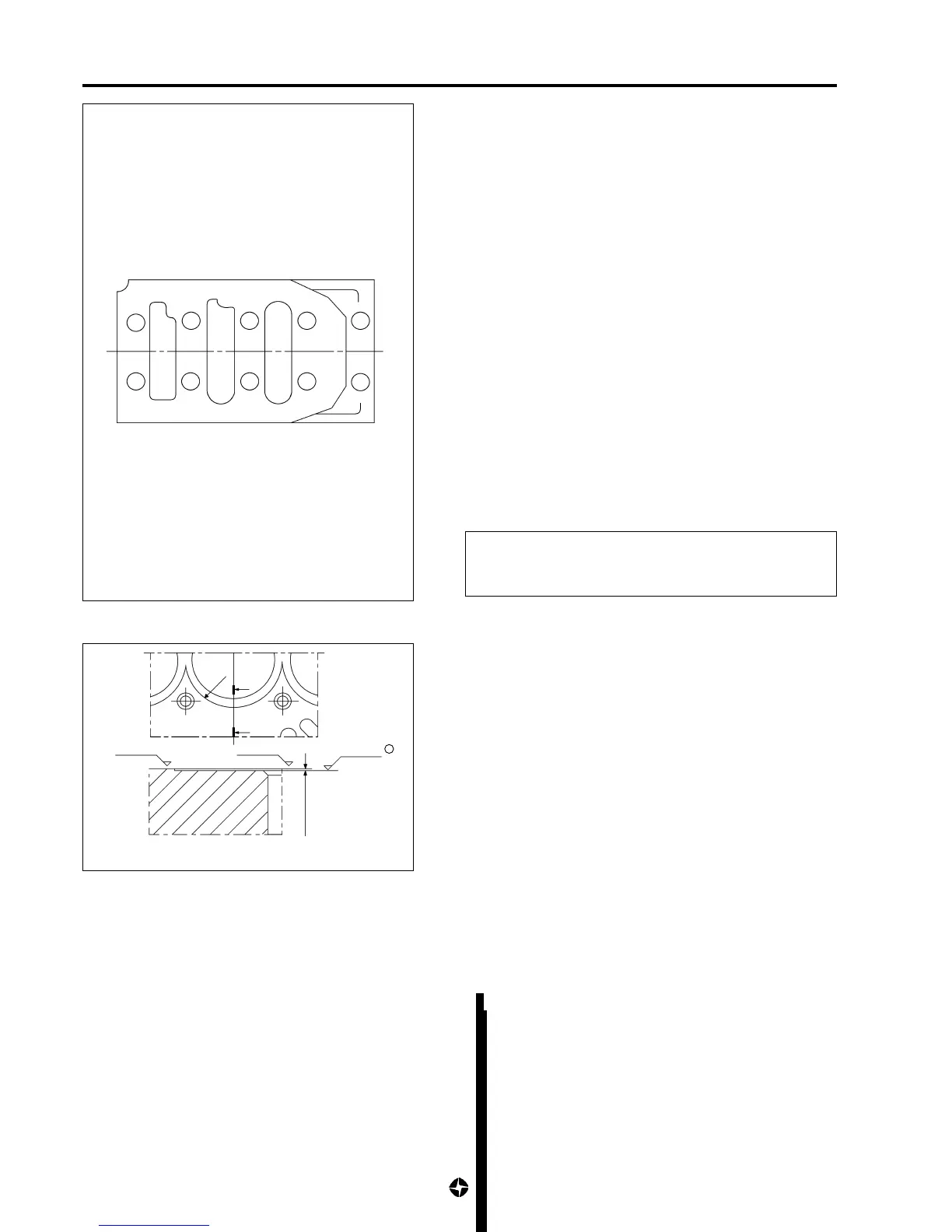

Cylinders lining up

Beforehand verifyings in the cylinders block

1) Before proceeding to the cylinders block lining, verify diametre

of ball bearings lodgings at the block as indicated; if results

are inadequate as specified substitute cylinders block.

• Install lower block over the upper one, without ball bearings

or gaskets.

• Tighten fixing screws to the specified tightening torque.

Tighten fixing screws in lower block following the order

stated herewith:

1

st

phase: 5 ± 0,5 kg-m (50 ± 5 Nm)

2

nd

phase: 90º ± 5º

• With dial gauge and an internal dimensions measuring

calliper, check that diameter of ball bearings housings at

the block adjusts to specified size

Diameter of the ball bearings lodgings at the block:

• Lodgings nº 1 - 2 - 3 - 4: 84,588 ÷ 84,614 mm

• Lodging nº 5: 90,588 ÷ 90,614 mm

CAUTION:

If the diameter of any housing is higher than

specified, substitute cylinders block.

A

B

A. Timing side

B. Side flying motor

7

8

3

4

2

1

6

5

10

9

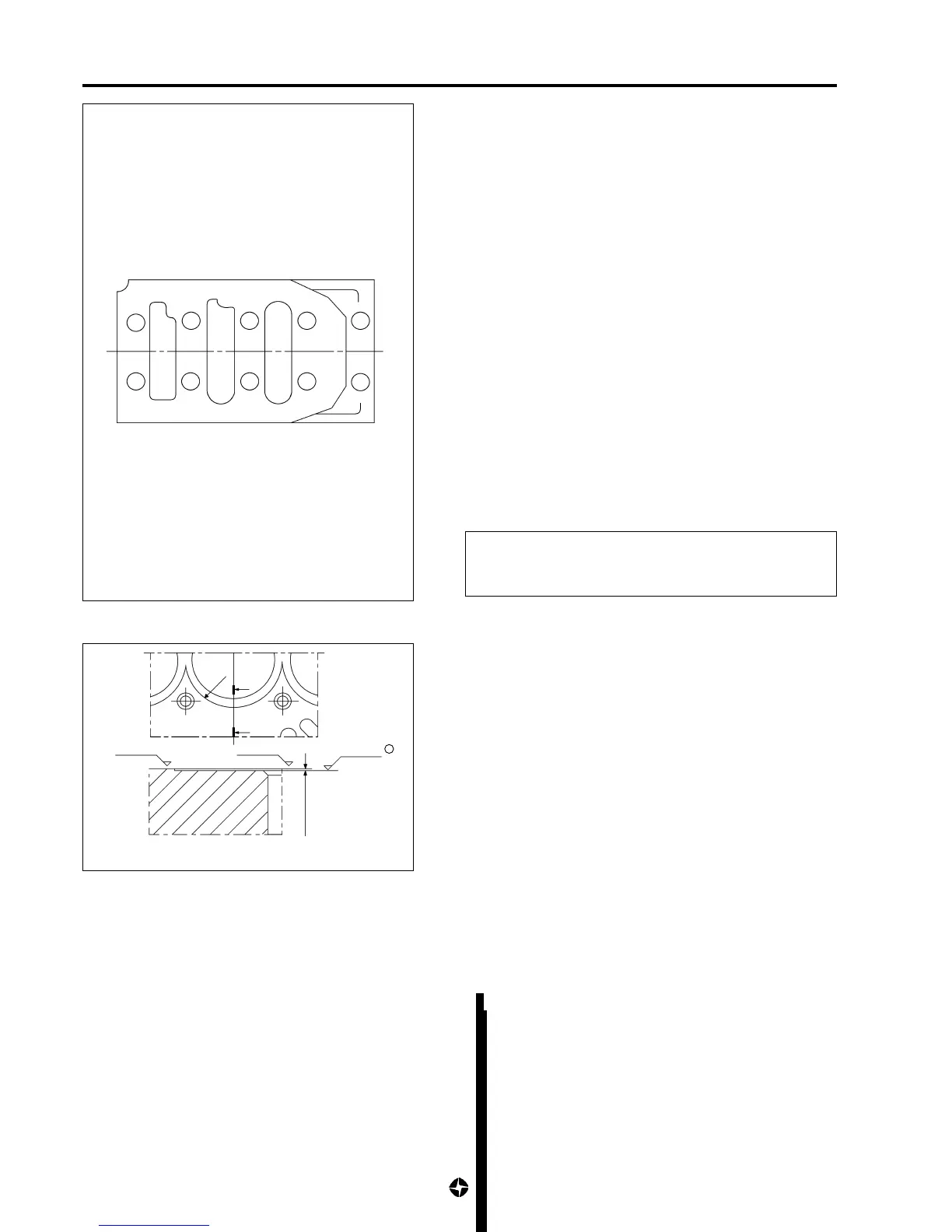

Cylinderslining up

1) Carry out levelling by milling at upper faced of block (Ø 111),

as shown .

2) Carry out mechanizing of four cylindres for installation of the

cylinders liners as indicated in the scheme "CYLINDERS

MECHANIZATION TO FIT CYLINDERS LINERS".

WT=10 - PASSO 5

*

1,6

**

R

a

< 1,0 µm- +

A

A

Ø 111

0,005 max

SECTION A-A

*

Plane bases

** Plane milling Ø 111

Loading...

Loading...