ENGINE REPAIR 6A-95

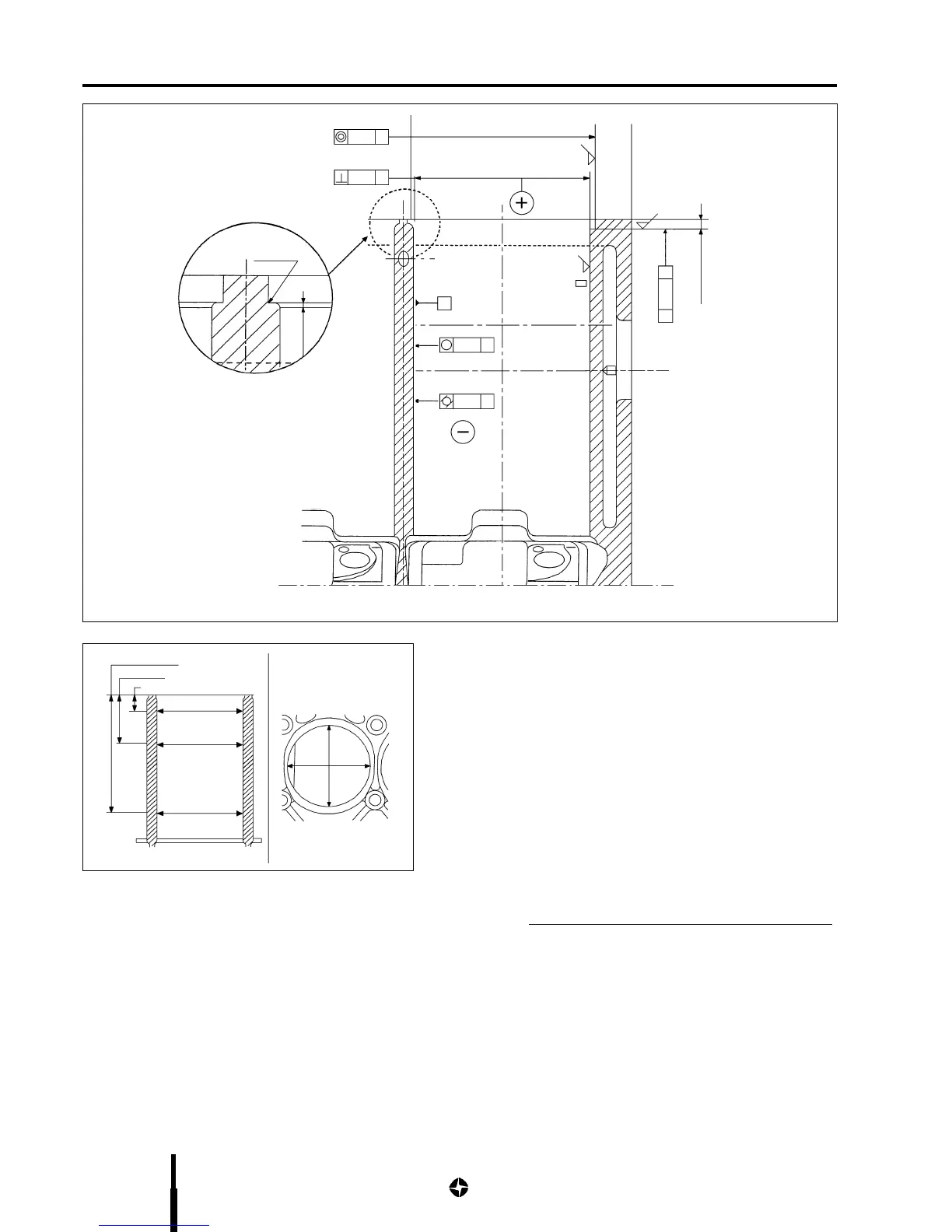

3) Once the four cylinders have been mechanized measure

each one using an internal dimensions caliper adjusted to

the nominal diameter size of mechanized cylinders.

Nominal diameter size to which the calliper must be

adjusted: 97,5

-0,11

Measuring should be done as follows:

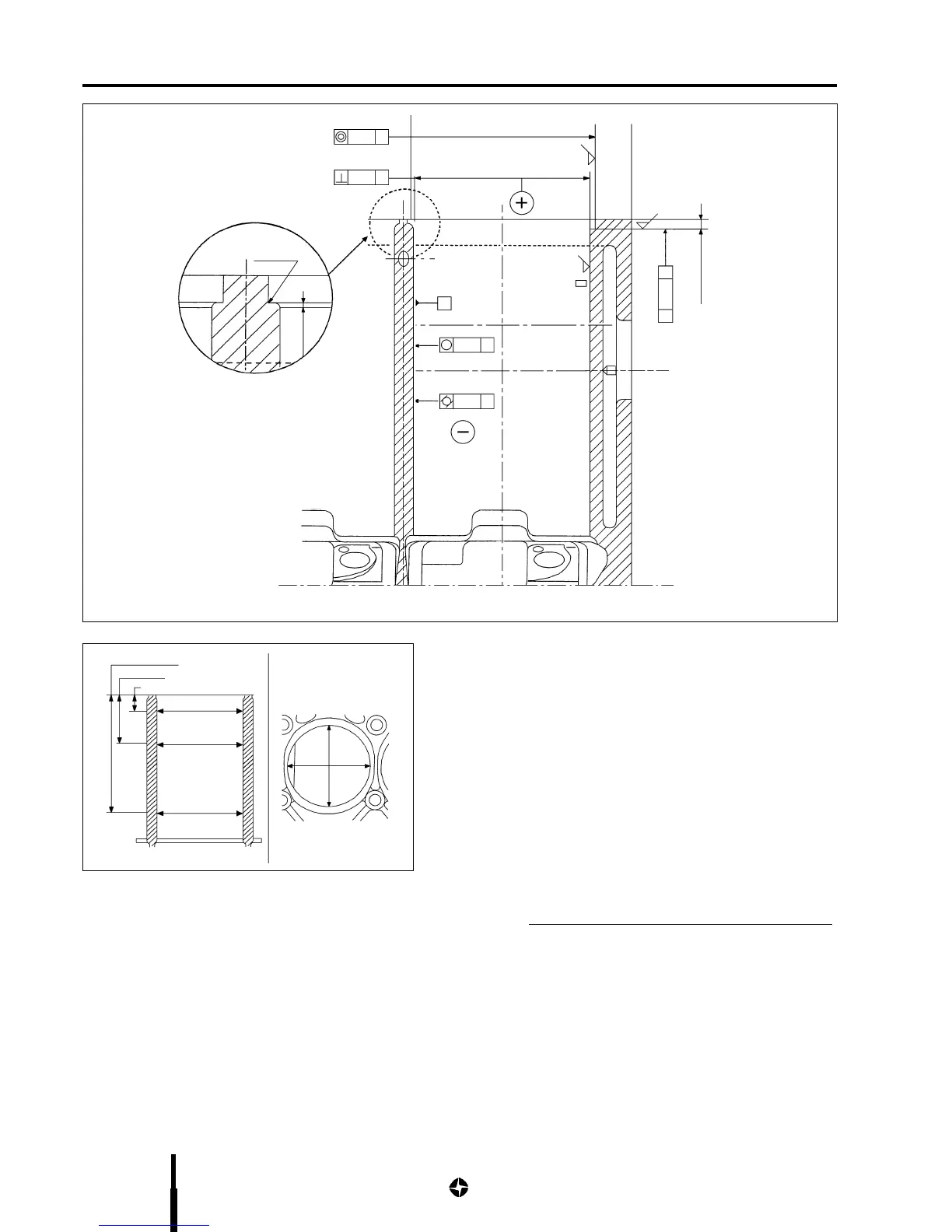

• Carry out three measurements at three different heights of

the cylinder as shown and at two planes perpendicular

one to another. One plane is parallel to the longitudinal

axle of engine (A) and another perpendicular (B).

• The mean diameter D

1

med must be specified and

calculated as follows

D

1med

=

NOTE:

The values between brackets are the heights to which

measurements from the upper face of block have to

be performed.

Mean diameter D1 med of mechanized cylinders to

be lined: 97,390 ÷ 97,450 mm

• The difference between the maximum and minimum

diameter (D

máx

y D

mín

)

must be below the specified value.

Maximum difference D

máx

y D

mín

: 0,03 mm

0,05 K

0,03 B

0,02

0,05

K

0,05 K

3

4,5 ± 0,1

Ø 101,07 ÷ 101,13

Ø 97,5

-0,05

-0,11

3

0,4

1 I

0,4÷0,5x45°

R 0,4÷0,6

A

A Longitudinal axis of the motor

AUTOMATED OF CYLINDERS to HOUSE SHIRTS

-0,05

B

A

142

50

10

A

1

(10) + A

1

(50) + A

1

(142) + B

1

(10) + B

1

(50) + B

1

(142)

6

££

££

£

1

st

mensuration

2

nd

mensuration

3

rd

mensuration

Loading...

Loading...