TRANSFER BOX 7D-27

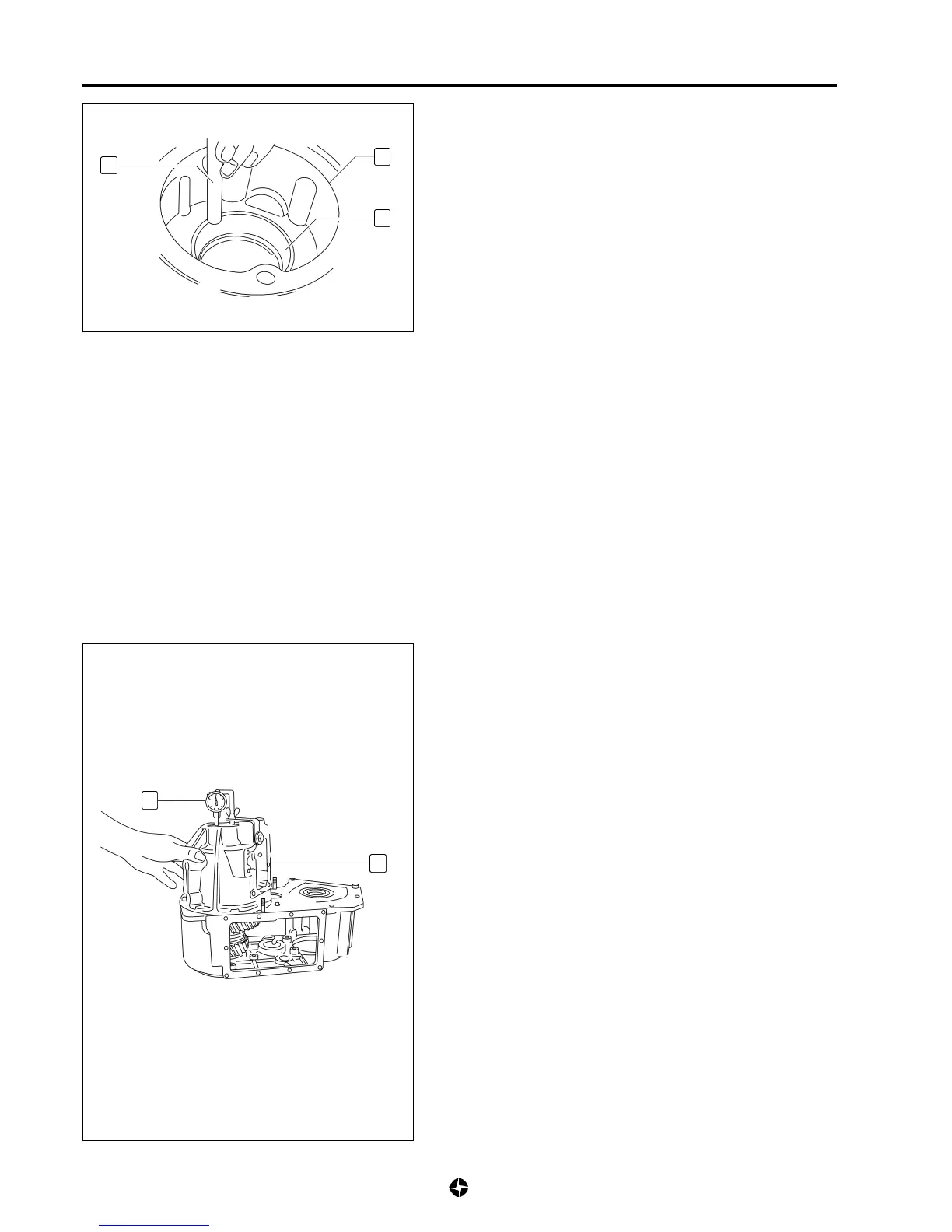

12) Completely sink the exterior ring of the main shaft front

bearing into the double traction casing. Use a soft rod (C).

65

68

C

13) Fit, provisionally, the double traction casing and tighten the

screws to the specified torque.

Torque for setscrews for double traction casing:

2,2 ÷ 2,8 Kg-m (22 ÷ 28 Nm)

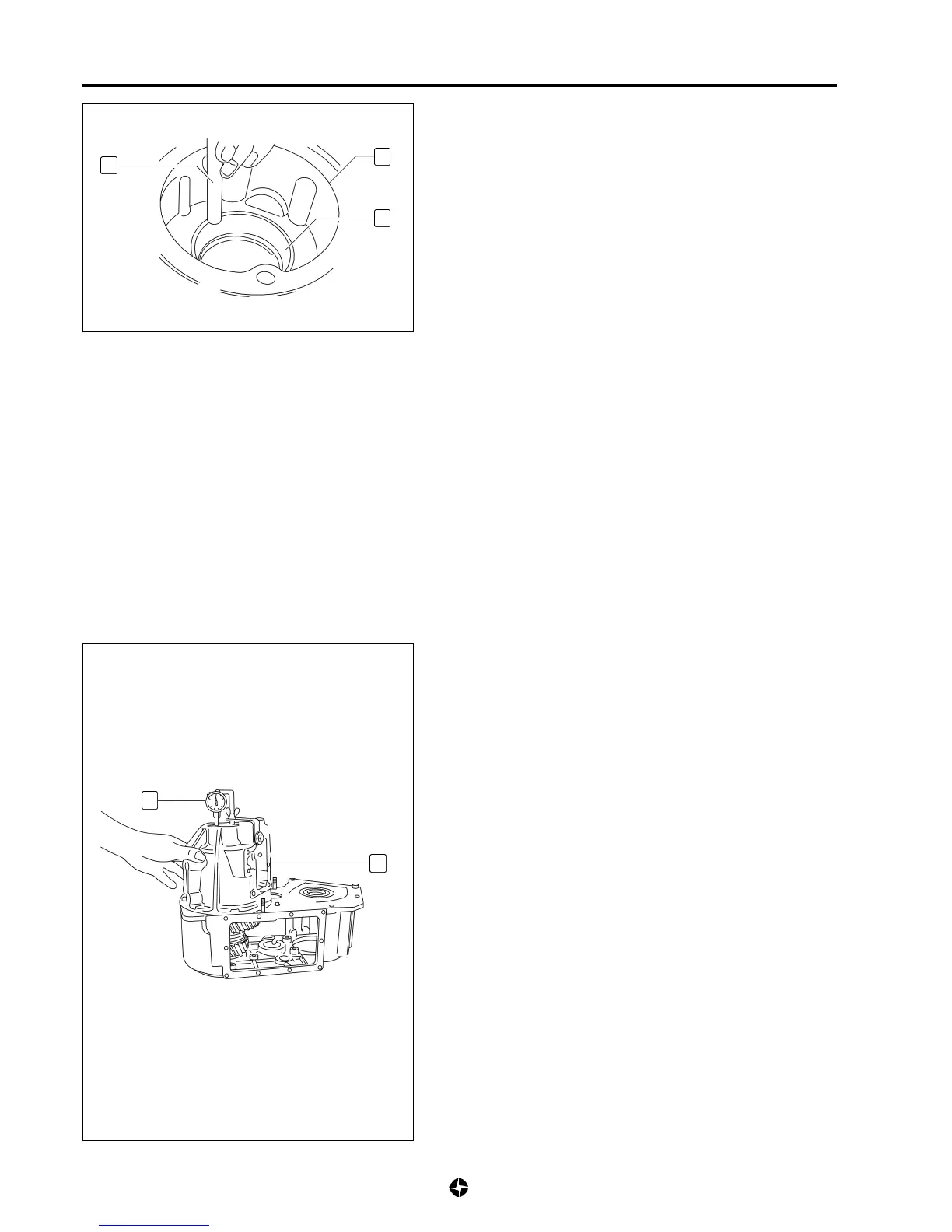

14) Firmly fix a meter (G) to the double traction casing (65) in

such a way that the probe is in contact with the front of the

main shaft.

15) Make sure that the meter link is long enough to measure

the longitudinal play of the main shaft.

16) Lever the "low" gears and move the entire main shaft

assembly upwards until it rests perfectly on its front bearing.

17) Determine the movement of the main shaft (shown on the

meter). Repeat the operation several times to do this.

18) Once the measure has been obtained, add to it the thickness

of the pre-tingten specified for the main shaft bearings.

Applicable thickness of pre-tingten:

0,025 ÷ 0,076 mm

19) The sum of these two measurements determines the exact

thickness of the assembly washer (69) which must be fitted

between the casing (65) and the ring (68).

G

65

NOTE:

Make sure that the assembly washers - which should

be between the box (65) and the ring - have not risen.

This is due to the fact that, as yet, the thickness is

unknown, but which will be determined shortly.

Loading...

Loading...