DIFFERENTIALS 7E-9

Revision

1) Examine all the components in case they show wear above

normal.

2) All the rolling components must be adjusted by pressure

except the rear one of the engaging pinion (tail), which must

be by sliding adjustment.

3) Check there are no shavings in the teeth and that the

housings, spherical as well as flat ones have no scratches,

or wear.

NOTE:

Replace gears or rolling parts wth pittings, excessive

wear or scratches.

Assemby

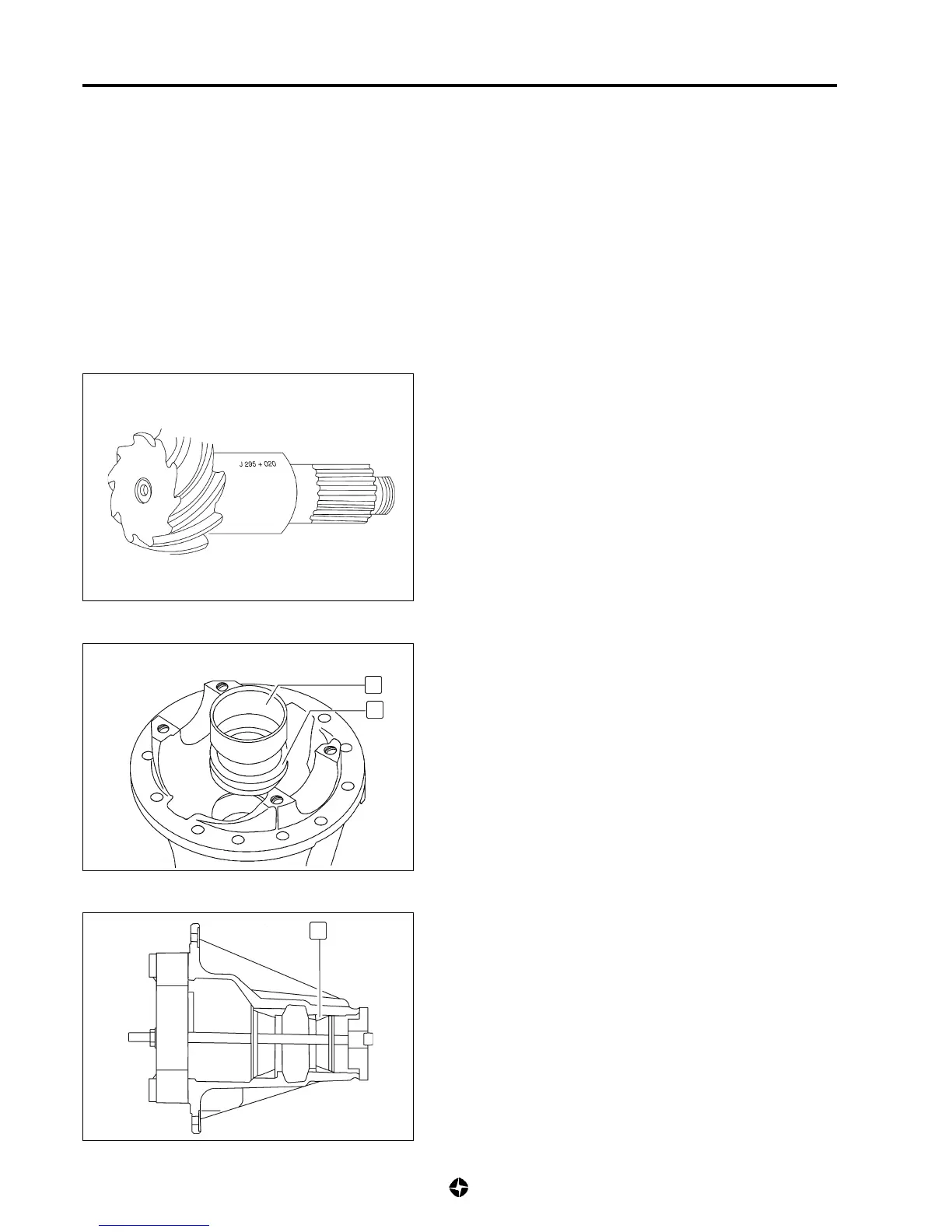

NOTE:

Before assembling pinion take note of the correcting

measure to be done engraved on the engaging pinion.

1) Write down the sign engraved in the pinion (+ 6 -), and the

numbers before the sign. Numbers and letters before the

sign correspond to the indenting for proper pairing which

must be the same as the one marked on the crown.

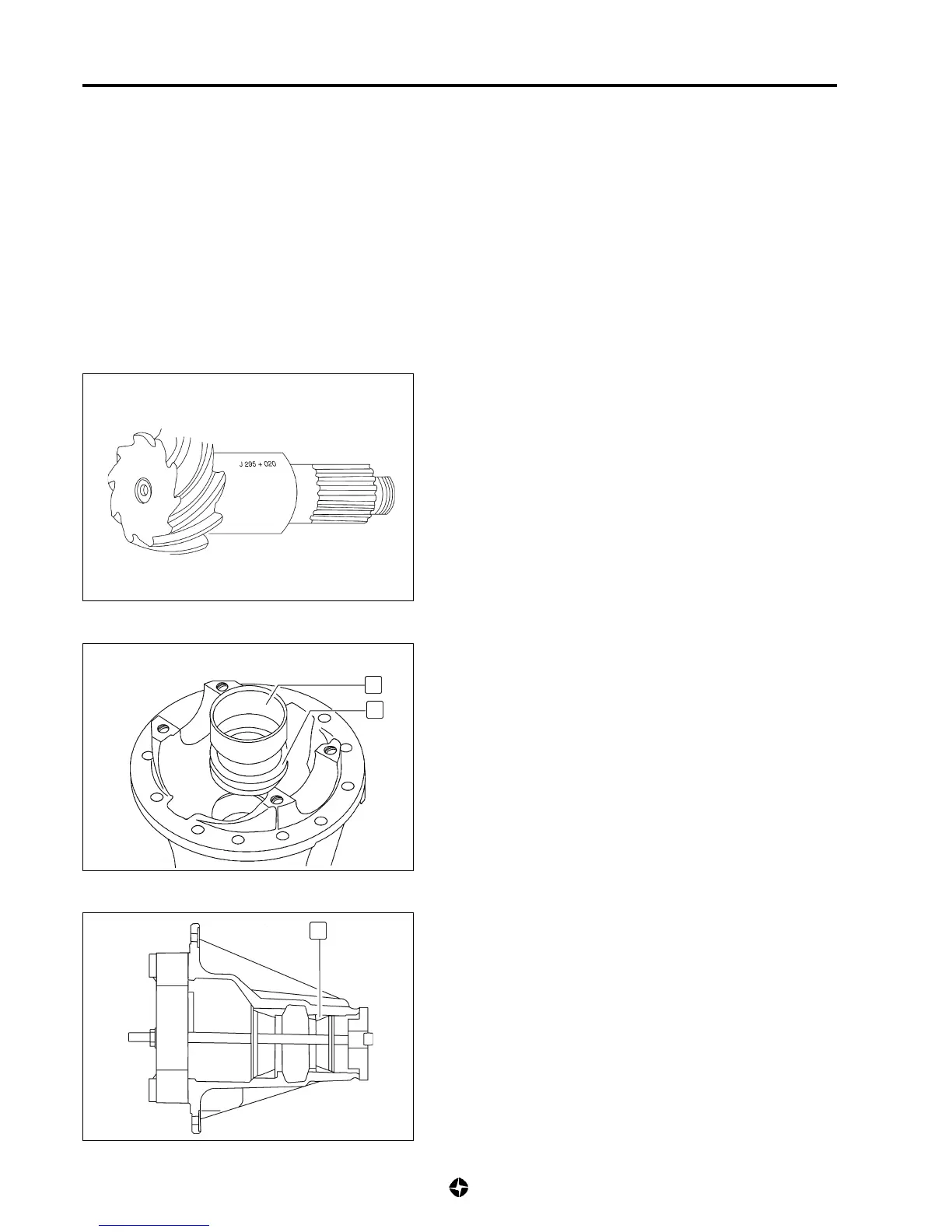

2) Install trail (18) of the head roller or journal and the adjusting

regulating washers (19), whose thickness must be initially

the same as the dismantled one.

NOTE:

In case that thickness value was lost assemble initially

with no less than 1.25 mm.

3) Assemble trail (17) of the tail roller.

NOTE:

To fit the two trails, a press with the appropriate tools

can be used or with special tools ref. 262757 y 262758.

18

19

17

Loading...

Loading...