7E- 10 DIFFERENTIALS

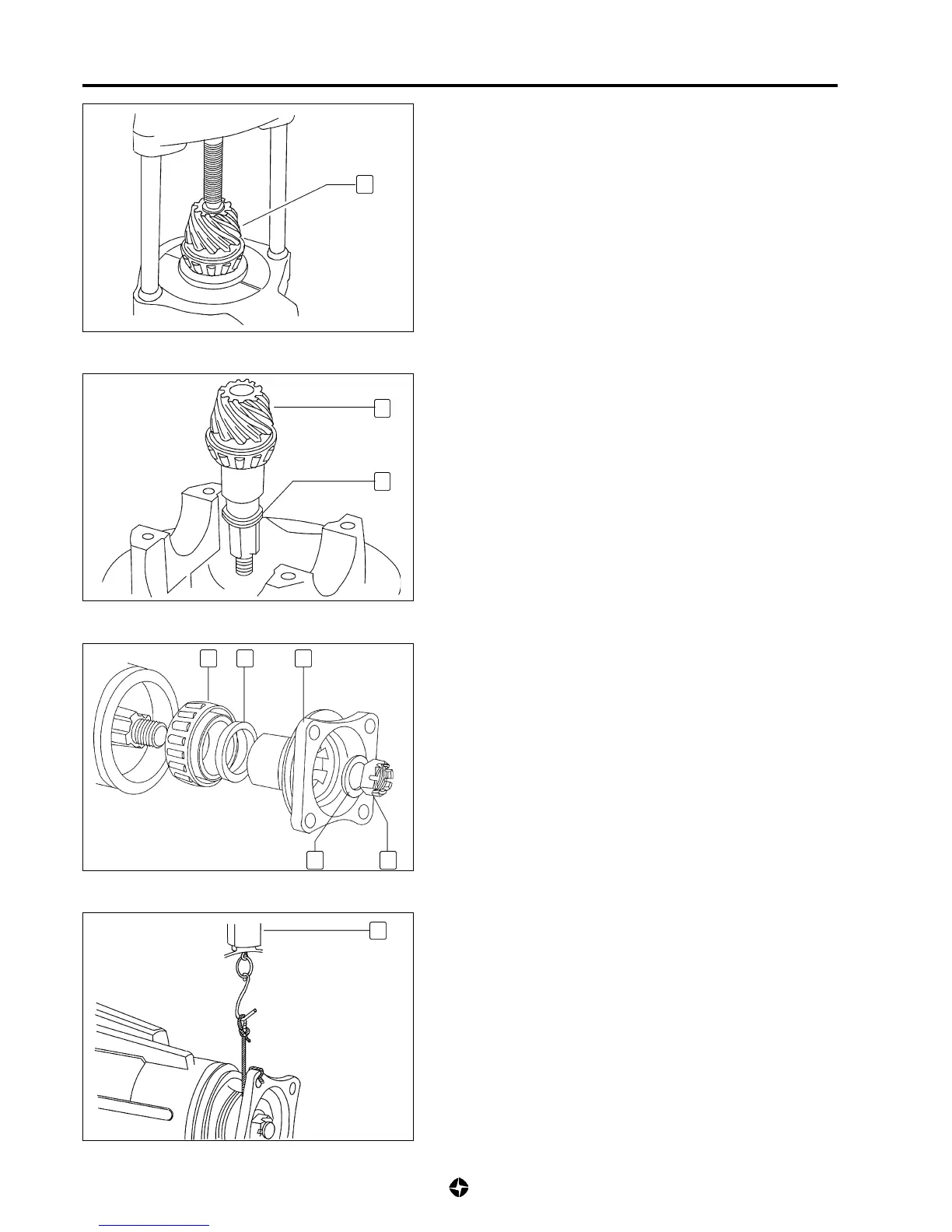

4) Assemble head roller (16) of pinion , using a press and

appropriate tools.

5) Place the ensemble engaging pinion (10) and its roller,

over the sump, placing in between the adjusting washers

(11).

NOTE:

Total thickness of adjusting washers (11) must be,

initially the same as the one dismantled. If this thickness

was lost, assemble initially a thickness of no less than

4.06 mm.

6) Assemble:

• Rear rolling element (9).

• Bushing of supplement (8).

• Flange (6).

• The nut (24) with its washer (25), tightened to the specified

torque.

Tightening torque nut fixing flange :

11,75 Kg-m (117,5 Nm)

NOTE:

• Lubricate rolling elements before assembling them

on the sump.

• Do not assemble oil seal jet.

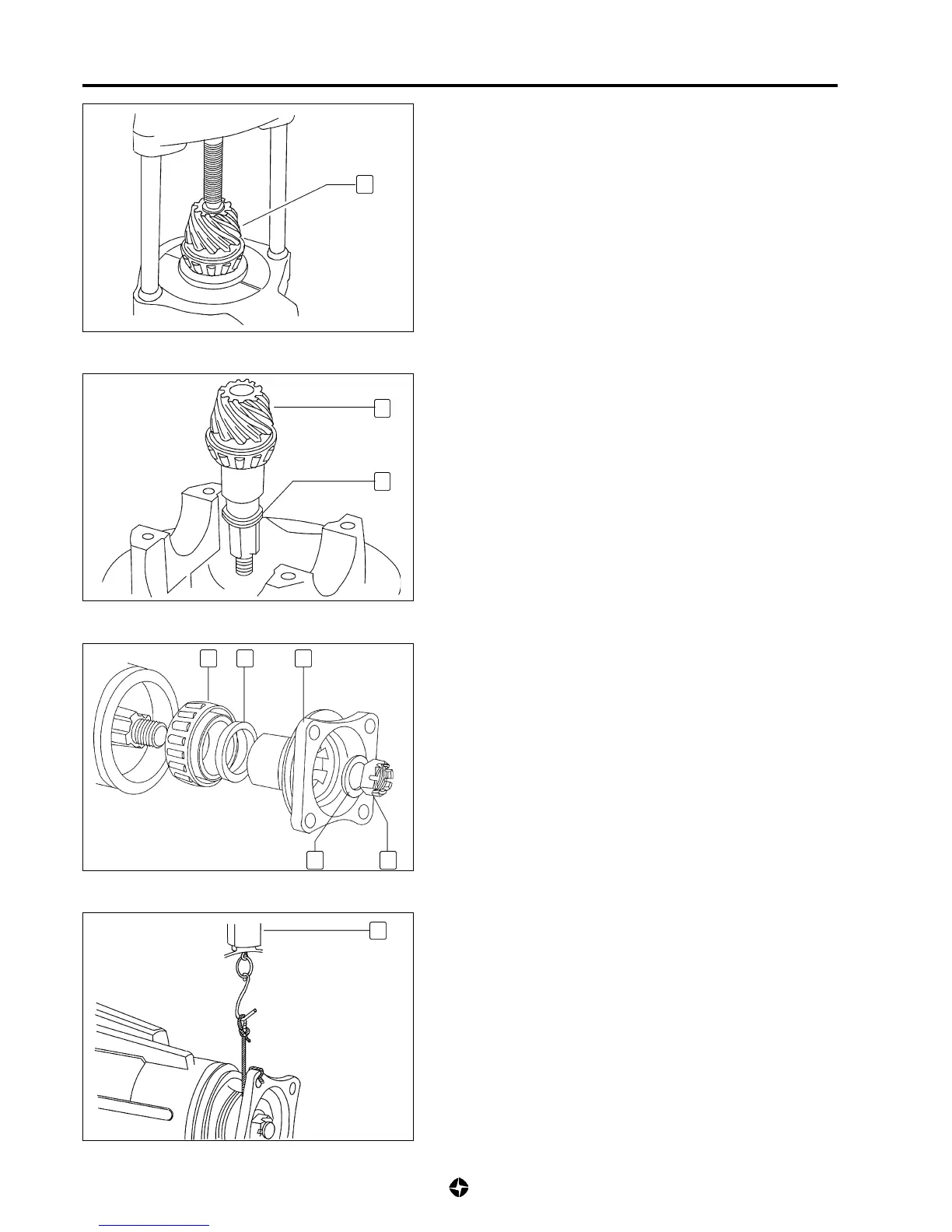

7) Wrap a piece of string in the flange as shown and connect

a dynamometer (B).

16

10

11

6

8

9

2425

B

Loading...

Loading...