Program instructions

7.7 Pulse output

S7-200 SMART

250 System Manual, 09/2015, A5E03822230-AC

Smooth transitions between pulse trains occur unless the active pulse train completes before

a new pulse train setup is captured by the execution of the PLS instruction.

-segment pipelining, the frequency has an upper limit of 65,535 Hz. If a higher

frequency is needed (up to 100,000 Hz), multiple

-segment pipelining must be used.

Multiple-Segment pipelining of PTO pulses

In multiple-segment pipelining, the S7-200 SMART automatically reads the characteristics of

each pulse train segment from a profile table located in V memory. The SM locations used in

this mode are the control byte, the status byte, and the starting V memory offset of the profile

table (SMW168, SMW178, or SMW578). Execution of the PLS instruction starts the multiple

segment operation.

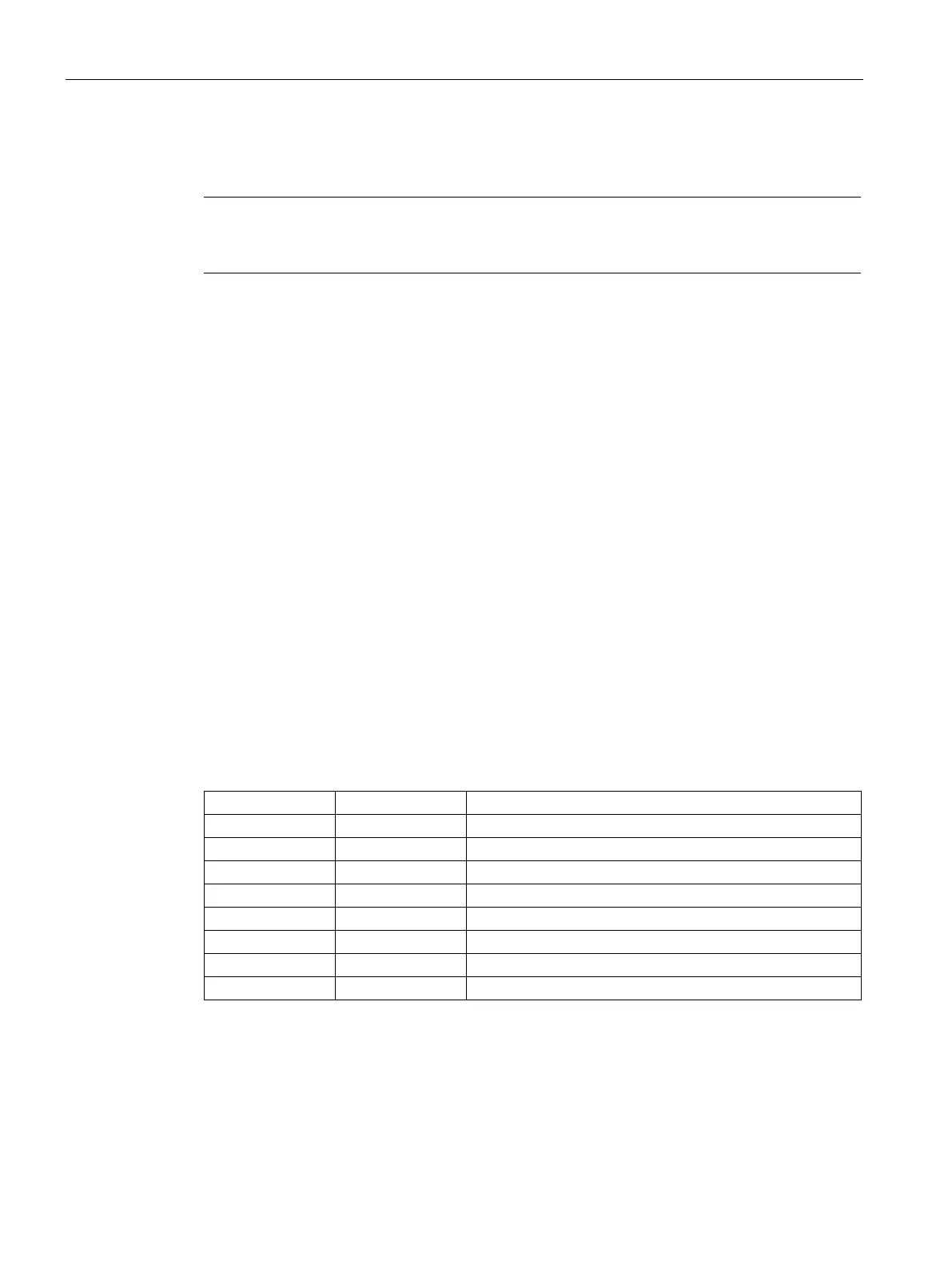

Each segment entry is 12 bytes in length and is composed of a 32 bit starting frequency, a

32 bit ending frequency, and a 32-bit pulse count value. The table below shows the format of

the profile table configured in V memory.

The PTO generator automatically increases or decreases the frequency linearly from the

starting frequency to the ending frequency. The frequency is increased or decreased by a

constant value at a constant rate. Once the number of pulses reaches the specified pulse

count, the next PTO segment is loaded. This sequence repeats until it reaches the end of the

profile. If a segment's time duration is less than 500 microseconds, the PTO pipeline

underflow bit (SM66.6, SM76.6, and SM566.6) can be set to 1 and the PTO operation

terminated. This indicates that the CPU does not have enough time to calculate the PTO

segment values.

While the PTO profile is operating, the number of the currently active segment is available in

SMB166, SMB176, or SMB576.

Table 7- 9 Profile table format for multiple-segment PTO operation

1

Description of table entries

Number of segments: 1 to 255

2

Starting Frequency (1 to 100,000 Hz)

Ending Frequency (1 to 100,000 Hz)

Pulse count (1 to 2,147,483,647)

Starting Frequency (1 to 100,000 Hz)

Ending Frequency (1 to 100,000 Hz)

Pulse count (1 to 2,147,483,647)

Entering a profile offset and number of segments that places any part of the profile table outside of

V memory generates a non-fatal error. The PTO function does not generate a PTO output.

Entering a value of 0 for the number of segments generates a non-fatal error. No PTO output is

Loading...

Loading...