PID loops and tuning

11.1 PID loop definition table

S7-200 SMART

468 System Manual, 09/2015, A5E03822230-AC

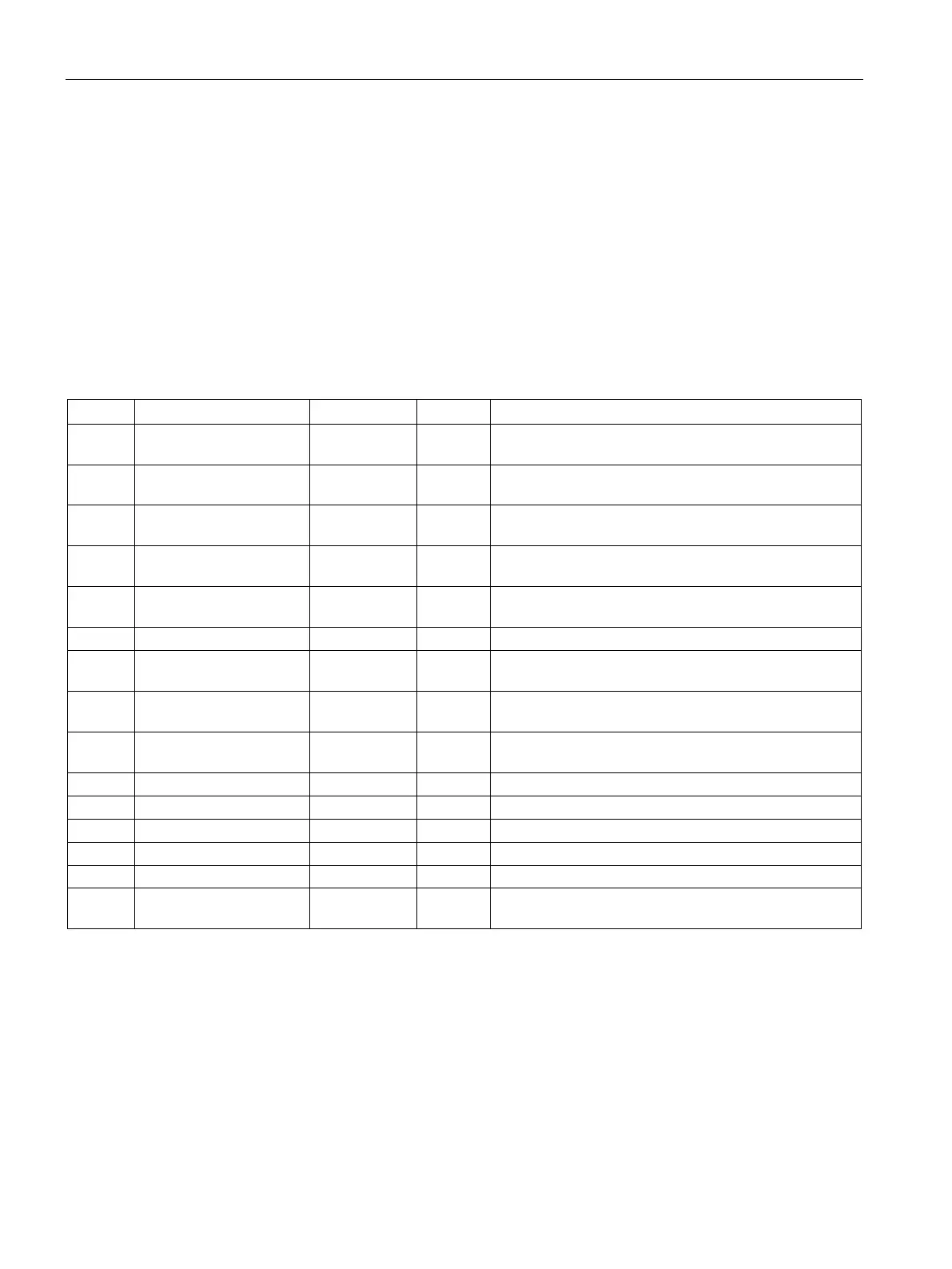

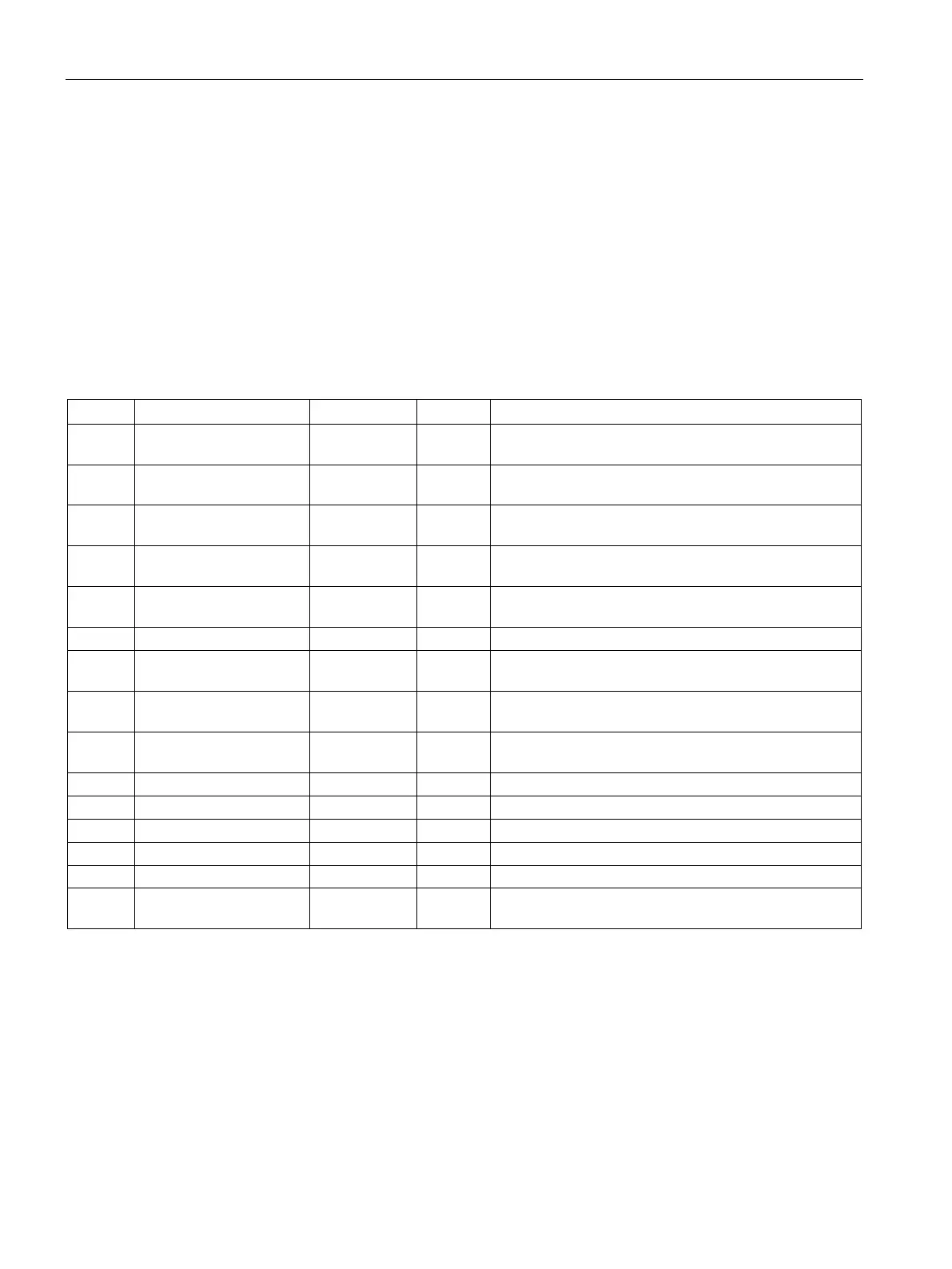

PID loop definition table

Eighty (80) bytes are allocated for the loop table from the starting address you enter for

Table (TBL) in the PID instruction box. The PID instruction for the S7-200 SMART CPU

references this loop table that contains the loop parameters.

If you use the PID Tune control panel, all interaction with the PID loop table is handled for

you by the control panel. If you need to provide auto-tuning capability from an operator

panel, your program must provide the interaction between the operator and the PID loop

table to initiate and monitor the auto-tuning process, and then apply the suggested tuning

values.

Table 11- 1 Loop table

0 Process variable (PV

n

) REAL In Contains the process variable, which must be scaled

4 Setpoint (SP

n

) REAL In Contains the setpoint, which must be scaled between

0.0 and 1.0.

8 Output (M

n

) REAL In/Out Contains the calculated output, scaled between 0.0 and

12 Gain (K

C

) REAL In Contains the gain, which is a proportional constant. Can

be a positive or negative number.

16 Sample time (T

S

) REAL In Contains the sample time, in seconds. Must be a posi-

Integral time or reset (T

I

)

Contains the integral time or reset, in minutes.

24 Derivative time or rate

D

REAL In Contains the derivative time or rate, in minutes.

28 Bias (MX) REAL In/Out Contains the bias or integral sum value between 0.0 and

32 Previous process varia-

n-1

REAL In/Out Contains the value of the process variable stored from

the last execution of the PID instruction.

'PIDA' (PID Extended Table, Version A): ASCII constant

44 Deviation (DEV) REAL In Normalized value of the maximum PV oscillation ampli-

tude (range: 0.025 to 0.25).

Loading...

Loading...