Open loop motion control

12.6 Subroutines created by the Motion wizard for the Axis of Motion

S7-200 SMART

506 System Manual, 09/2015, A5E03822230-AC

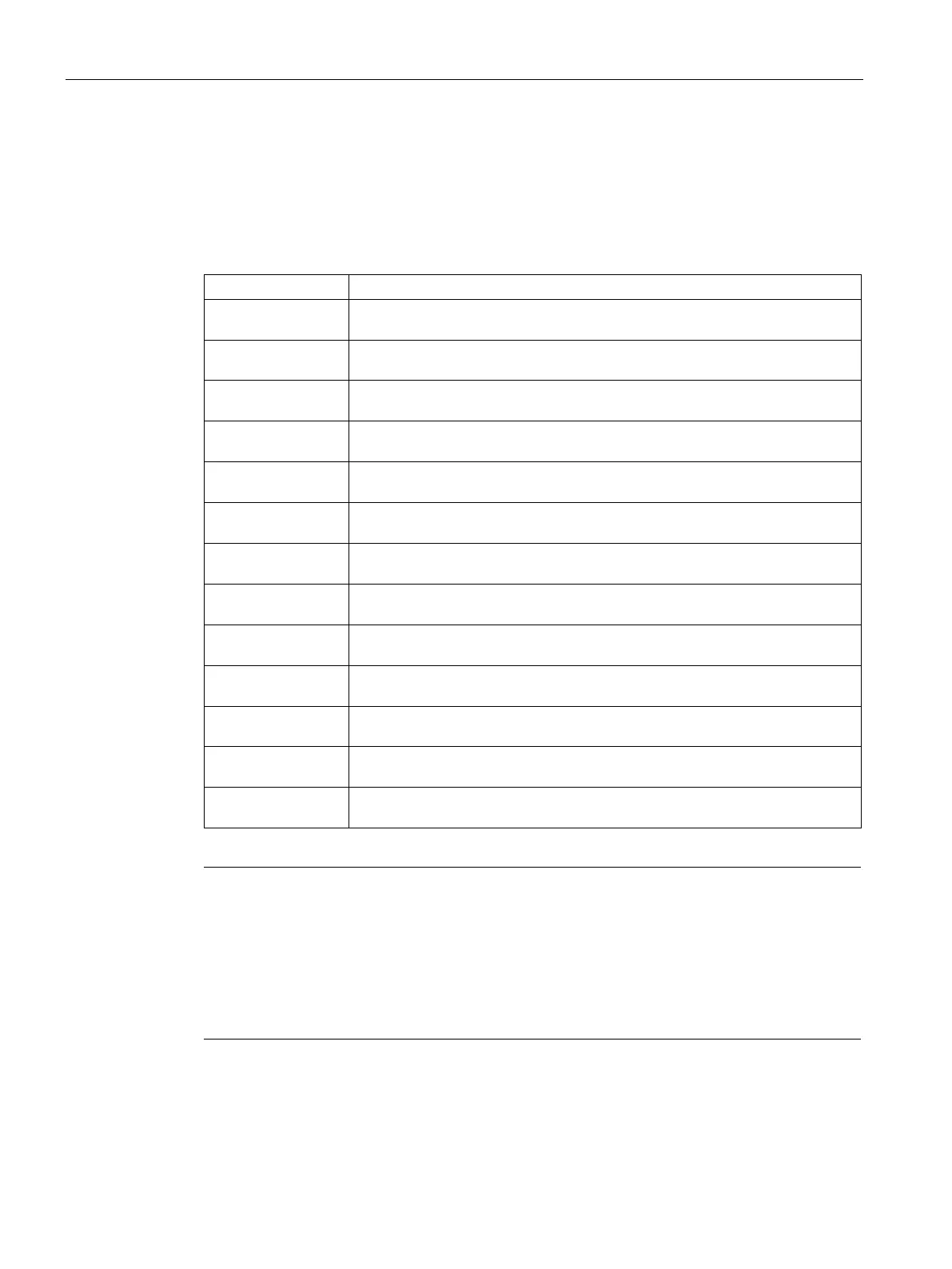

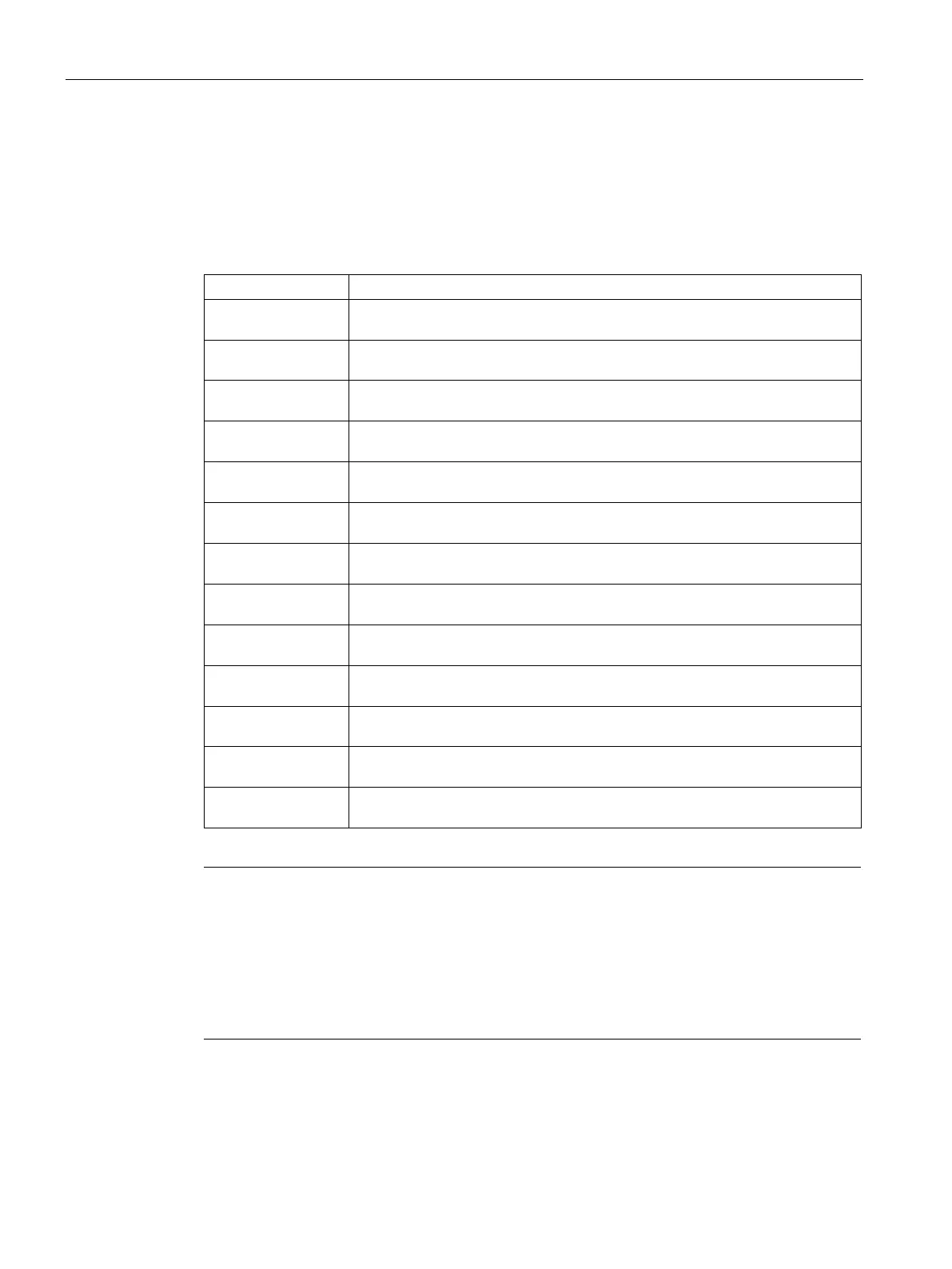

Subroutines created by the Motion wizard for the Axis of Motion

You must ensure for each motion action that only one motion subroutine is active at a time in

addition to the AXISx_CTRL, which must be active every scan. Each motion subroutine is

prefixed with an "AXISx_" where "x" is the axis number channel. There are 13 motion

subroutines.

AXISx_CTRL

Provides initialization and overall control of the axis

AXISx_MAN

(Page 509)

Used for manual mode operation of the axis

AXISx_GOTO

Commands the axis to go to a specified location

AXISx_RUN

Commands the axis to execute a configured motion profile

AXISx_RSEEK

Initiates a reference point seek operation

AXISx_LDOFF

Establishes a new zero position that is offset from the reference point position

AXISx_LDPOS

Changes the axis position to a new value

AXISx_SRATE

Modifies the configured acceleration, deceleration, and jerk compensation

AXISx_DIS

Controls the DIS output

AXISx_CFG

Reads the configuration block and updates the axis setup as required

AXISx_CACHE

Pre-caches a configured motion profile

AXISx_RDPOS

Returns the current axis position

AXISx_ABSPOS

Reads the absolute position value from a SINAMICS V90 servo drive

Note

The motion subroutines increase the

amount of memory required for your program by up to

bytes. You can delete unused motion subroutines to reduce the amount of memory

required. To prevent the generation of unneeded motion subroutines, uncheck the

"Generate" box for each unneeded subrout

ine in the "Components" node of the Motion

wizard. To restore generation of a particular motion subroutine, start the Motion wizard

again, navigate to the "Components" node, and check the "Generate" box for the subroutine.

Click the "Generate" button to re

build the wizard-generated subroutines.

Using the Motion wizard (Page 481)

Loading...

Loading...