PID loops and tuning

11.4 Auto-tune sequence

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

473

The deviation parameter specifies the desired peak-to-peak swing of the PV around the

setpoint. If you select to automatically determine this value, the desired deviation of the PV is

computed by multiplying the hysteresis value by 4.5. The output will be driven proportionally

to induce this magnitude of oscillation in the process during auto-tuning.

The auto-tuning sequence begins after the hysteresis and deviation values have been

determined. The tuning process begins when the initial output step is applied to the loop

output.

This change in output value causes a corresponding change in the value of the process

variable. When the output change drives the PV away from setpoint far enough to exceed

the hysteresis boundary, a zero-crossing event is detected by the auto-tuner. Upon each

zero-crossing event, the auto-tuner drives the output in the opposite direction.

The tuner continues to sample the PV and waits for the next zero-crossing event. The tuner

requires a total of twelve zero-crossings to complete the sequence. The magnitude of the

observed peak-to-peak PV values (peak error) and the rate at which zero-crossings occur

are directly related to the dynamics of the process.

Early in the auto-tuning process, the output step value is proportionally adjusted once to

induce subsequent peak-to-peak swings of the PV to more closely match the desired

deviation amount. Once the adjustment is made, the new output step amount is written into

the Actual Step Size field (ASTEP) of the loop table.

If the time between zero-crossings exceeds the zero-crossing watchdog interval time, the

auto-tuning sequence is terminated with an error. The default value for the zero-crossing

watchdog interval time is two hours.

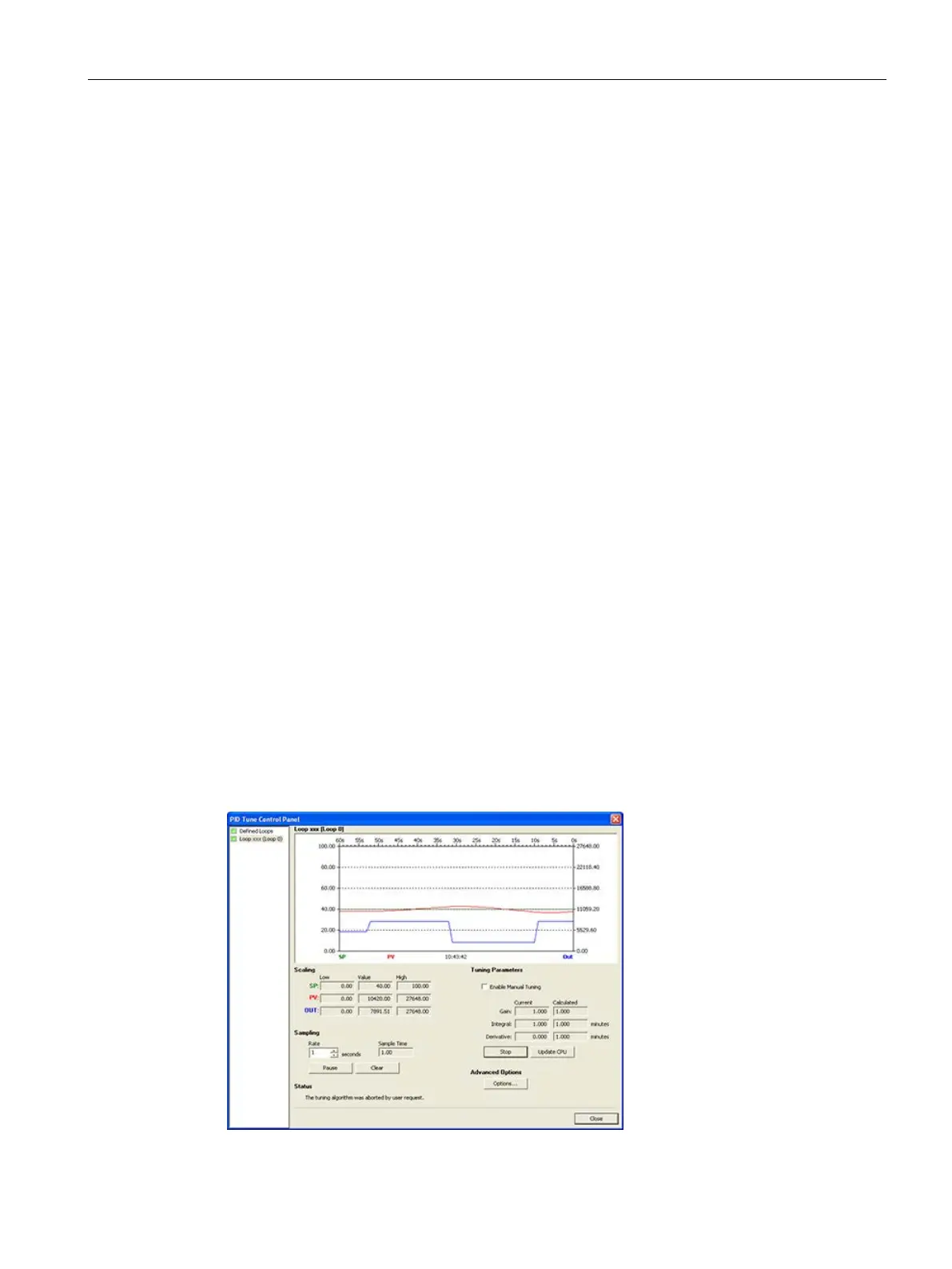

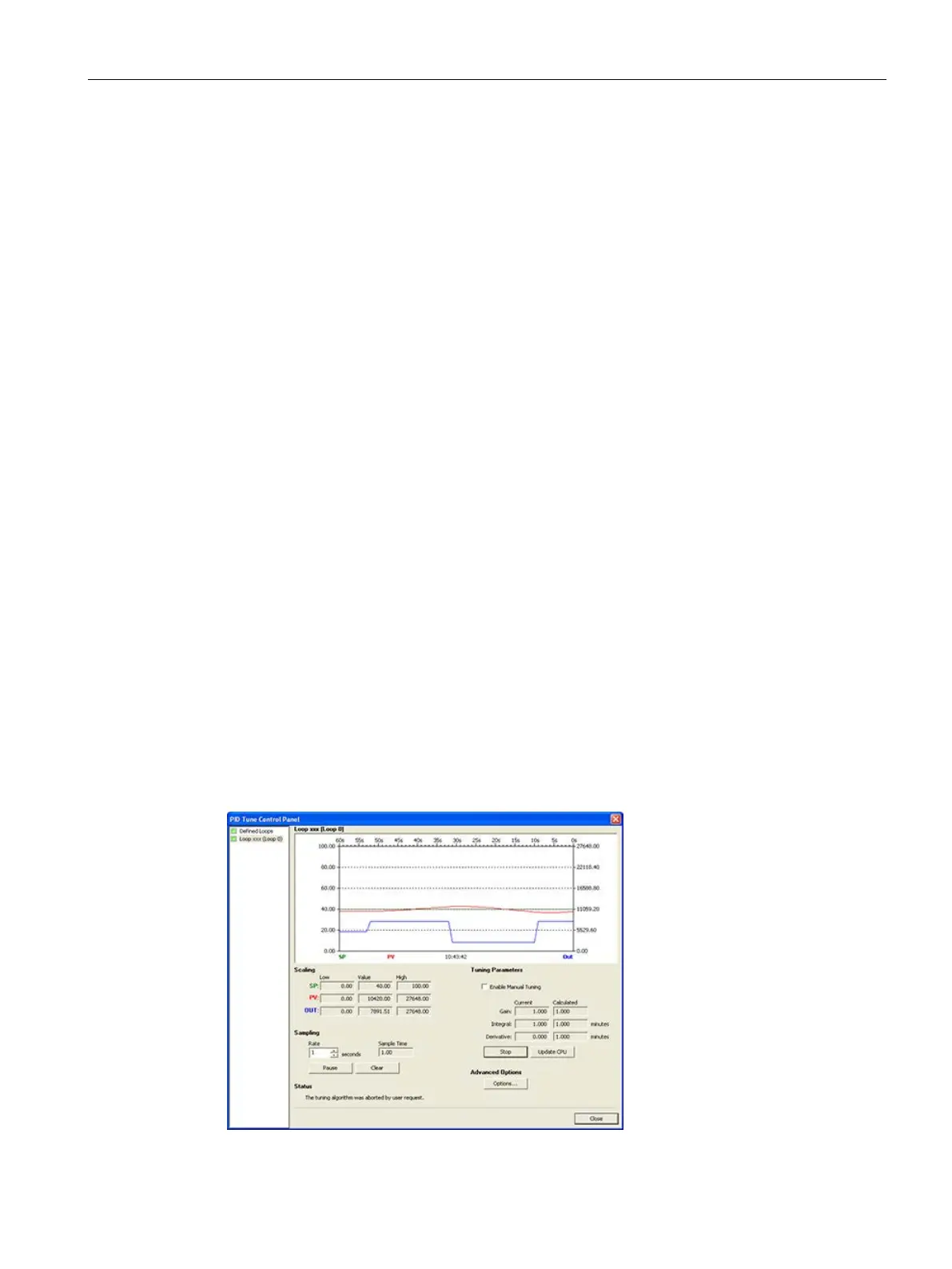

The following figure shows the output and process variable behaviors during an auto-tuning

sequence on a direct acting loop. You use the PID Tune control panel to initiate and monitor

the tuning sequence.

Loading...

Loading...