Program instructions

7.9 PID

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

279

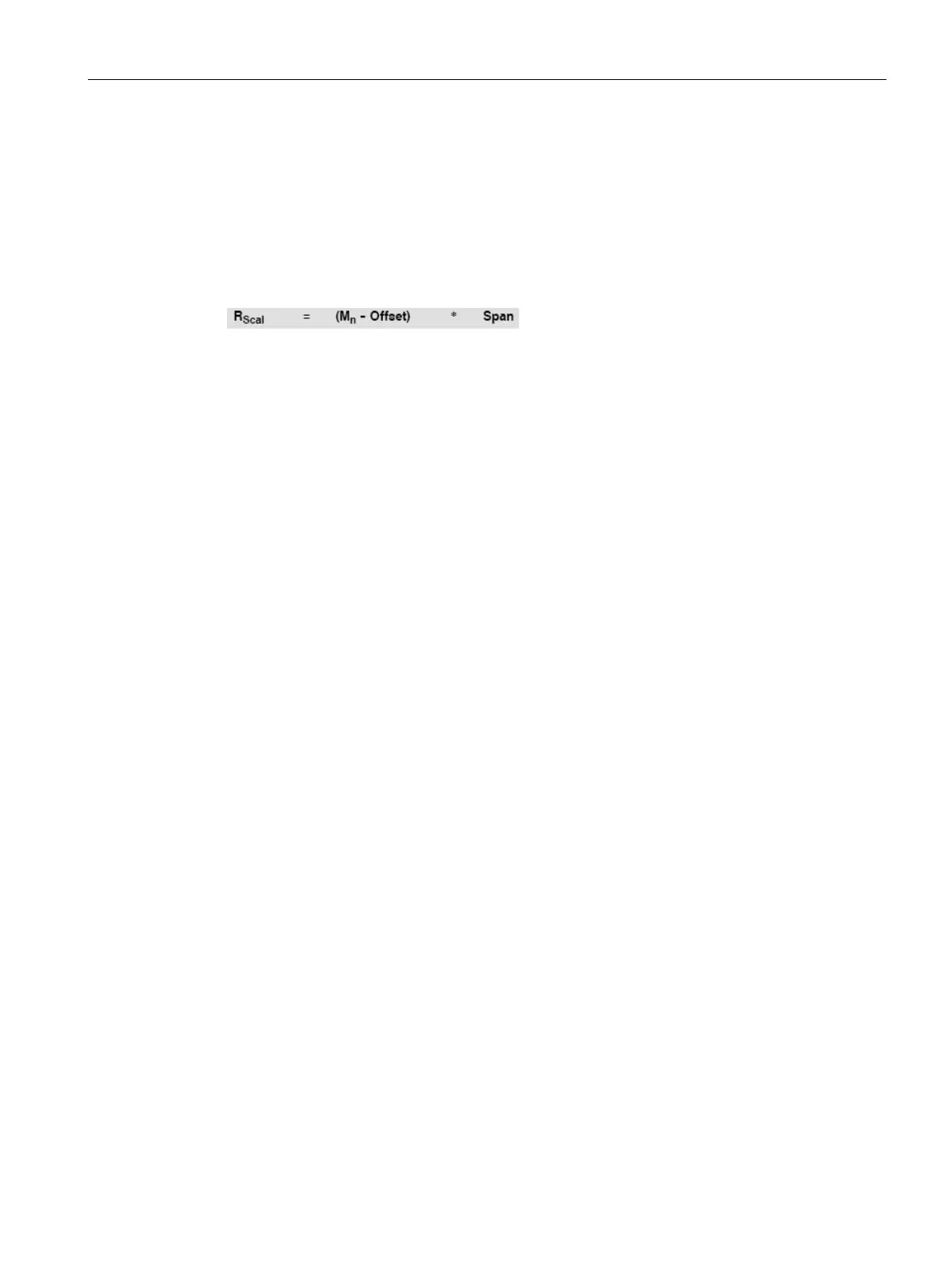

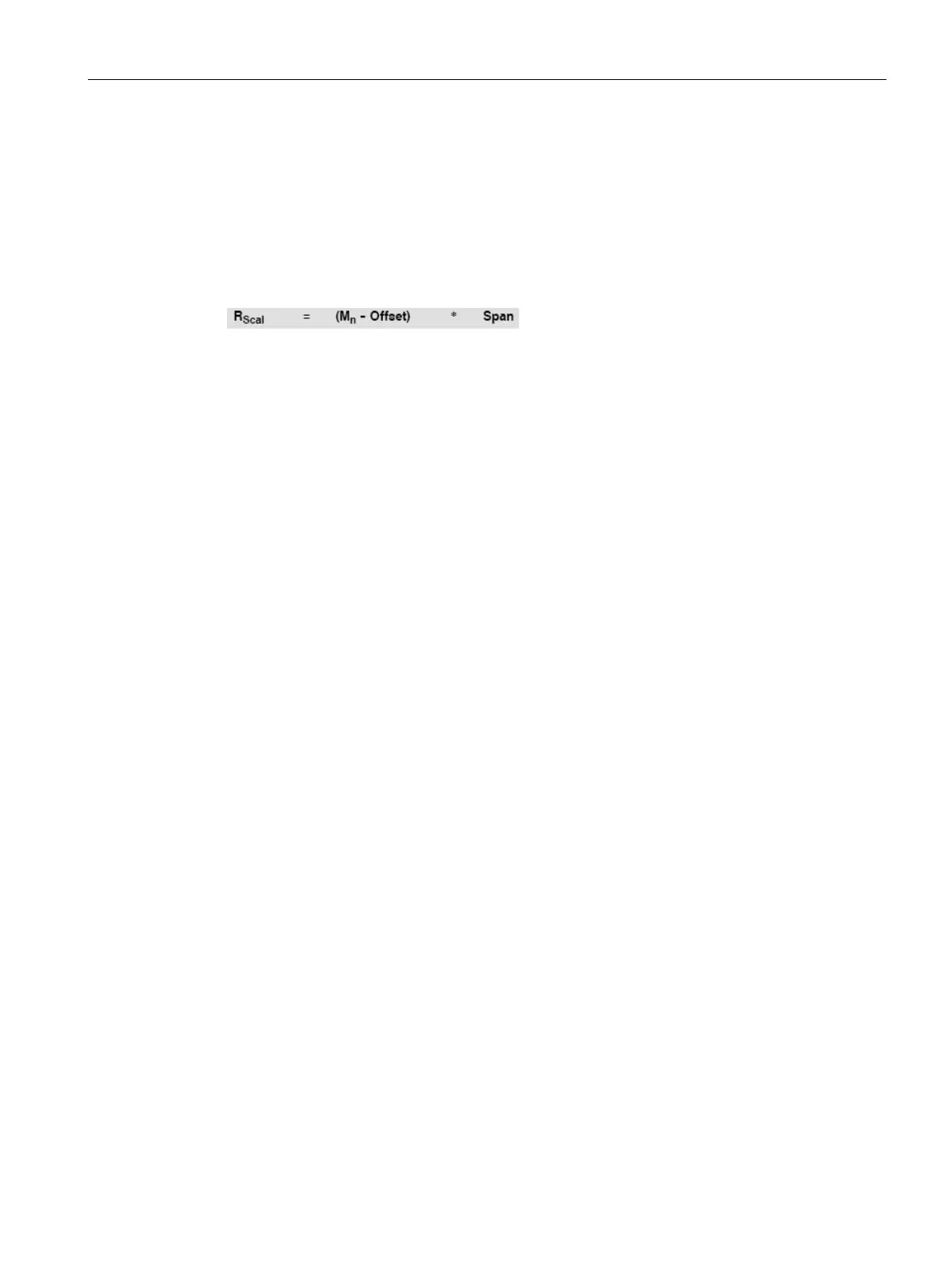

Converting the loop output to a scaled integer value

The loop output is the control variable, such as the throttle setting of the cruise control on an

automobile. The loop output is a normalized, real number value between 0.0 and 1.0. Before

the loop output can be used to drive an analog output, the loop output must be converted to

a 16-bit, scaled integer value. This process is the reverse of converting the PV and SP to a

normalized value. The first step is to convert the loop output to a scaled, real number value

using the formula given below:

is the scaled, real number value of the loop output

is the normalized, real number value of the loop output

Offset is 0.0 for unipolar values

is 0.5 for bipolar values

Span is the maximum possible value minus the minimum possible value

= 27,648 for unipolar values (typical)

= 55,296 for bipolar values (typical)

The following instruction sequence shows how to scale the loop output:

//Moves the loop output to the accumulator

//Include this statement only if the value is bipolar

//Scales the value in the accumulator

Next, the scaled, real number value representing the loop output must be converted to a 16-

bit integer. The following instruction sequence shows how to do this conversion:

//Converts the real number to a 32-bit integer

//Converts the value to a 16-bit integer

//Writes the value to the analog output

Forward- or reverse-acting loops

The loop is forward-acting if the gain is positive and reverse-acting if the gain is negative.

(For I or ID control, where the gain value is 0.0, specifying positive values for integral and

derivative time will result in a forward-acting loop, and specifying negative values will result

in a reverse-acting loop.)

The process variable and setpoint are inputs to the PID calculation. Therefore the loop table

fields for these variables are read but not altered by the PID instruction.

The output value is generated by the PID calculation, so the output value field in the loop

table is updated at the completion of each PID calculation. The output value is clamped

between 0.0 and 1.0. The output value field can be used as an input by the user to specify

an initial output value when making the transition from manual control to PID instruction

(auto) control of the output. (See the discussion in the "Modes" section below.)

Loading...

Loading...