Open loop motion control

12.2 Using motion control

S7-200 SMART

486 System Manual, 09/2015, A5E03822230-AC

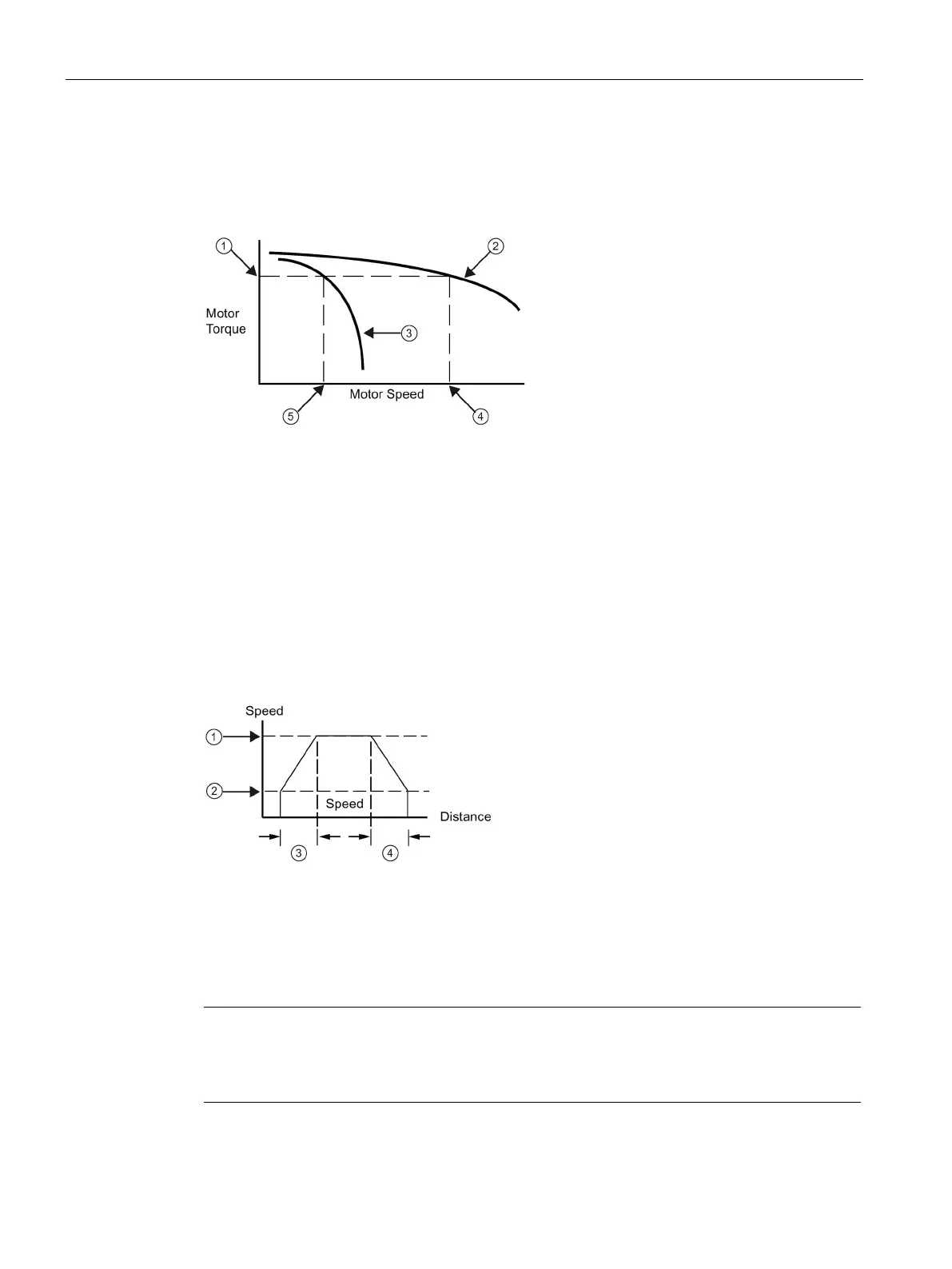

Motor data sheets have different ways of specifying the start/stop (or pull-in/pull-out) speed

for a motor and given load. Typically, a useful SS_SPEED value is 5% to 15% of the

MAX_SPEED value. To help you select the correct speeds for your application, refer to the

data sheet for your motor. The following figure shows a typical motor torque/speed curve.

Torque required to drive the load

Motor torque versus speed characteristic

Start/Stop speed versus torque: This curve moves towards lower speed as the load inertia

Maximum speed that the motor can drive the load: MAX_SPEED should not exceed this value.

Start/Stop speed (SS_SPEED) for this load

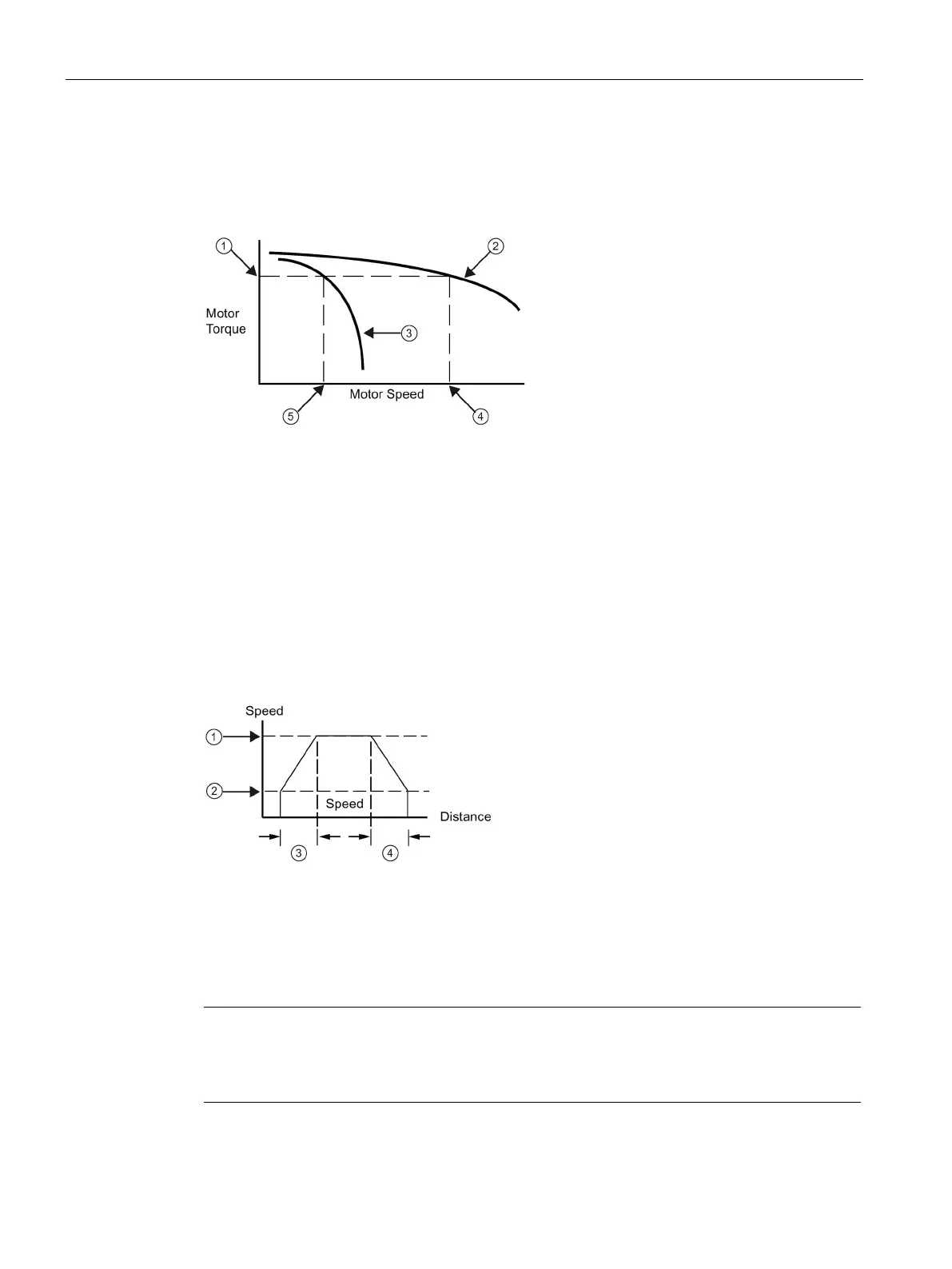

Entering the acceleration and deceleration times

As part of the configuration, you set the

acceleration and deceleration times. The

default setting for bot

h the acceleration

time and the deceleration time is 1 se

c-

ond. Typically, motors can work with

less than 1 second. See the following

figure.

① MAX_SPEED

② SS_SPEED

③ ACCEL_TIME

④ DECEL_TIME

Note

Motor acceleration and deceleration times are determined by trial and error. You should start

by entering a large value. Optimize these settings for the application by gradually reducing

the times until the motor starts to stall.

Loading...

Loading...