Open loop motion control

12.7 Using the AXISx_ABSPOS subroutine to read the absolute position from a SINAMICS servo drive

S7-200 SMART

524 System Manual, 09/2015, A5E03822230-AC

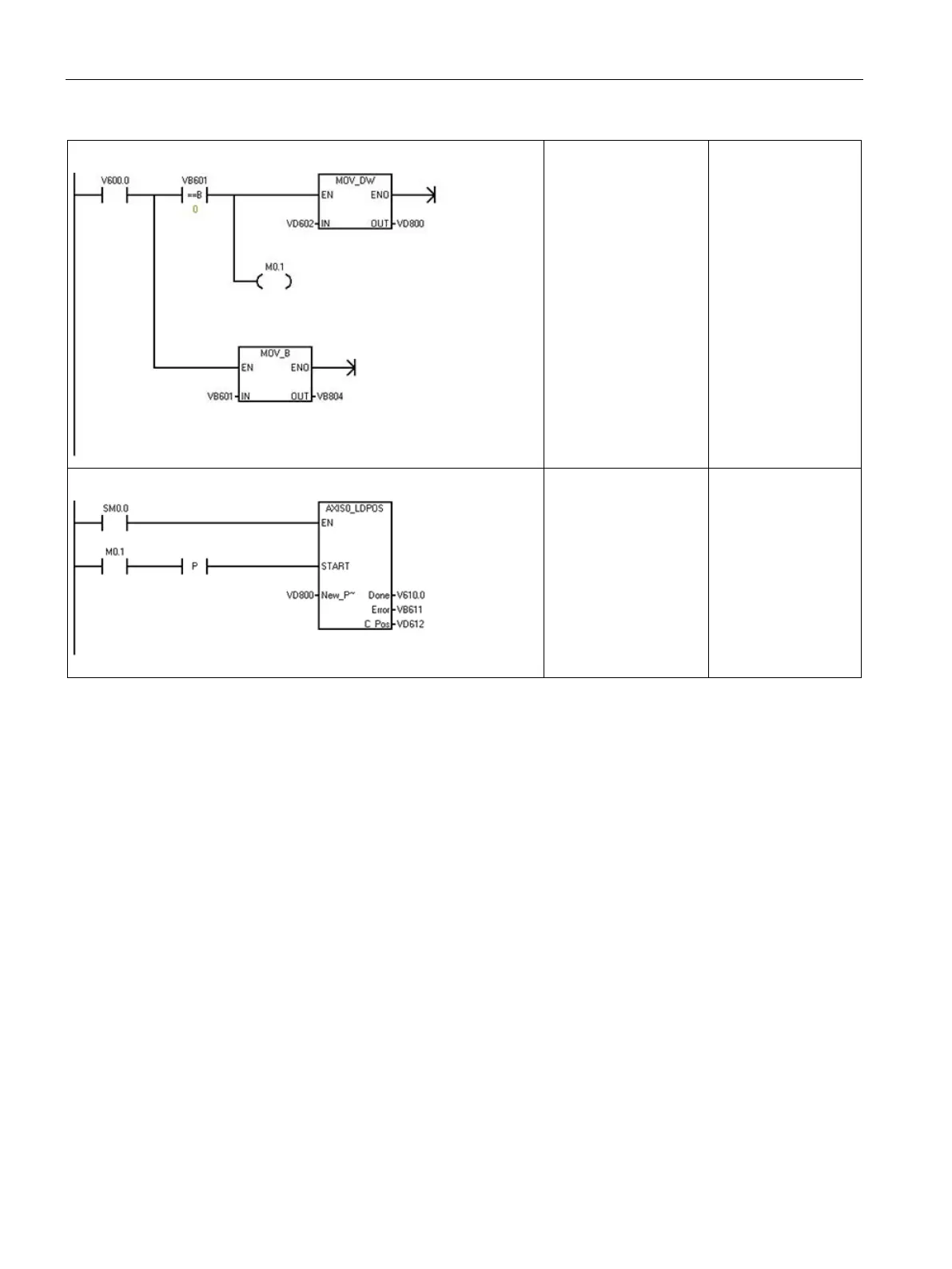

Network 2:

When the operation is

done, capture the error

code and also capture

the servo position, if no

error.

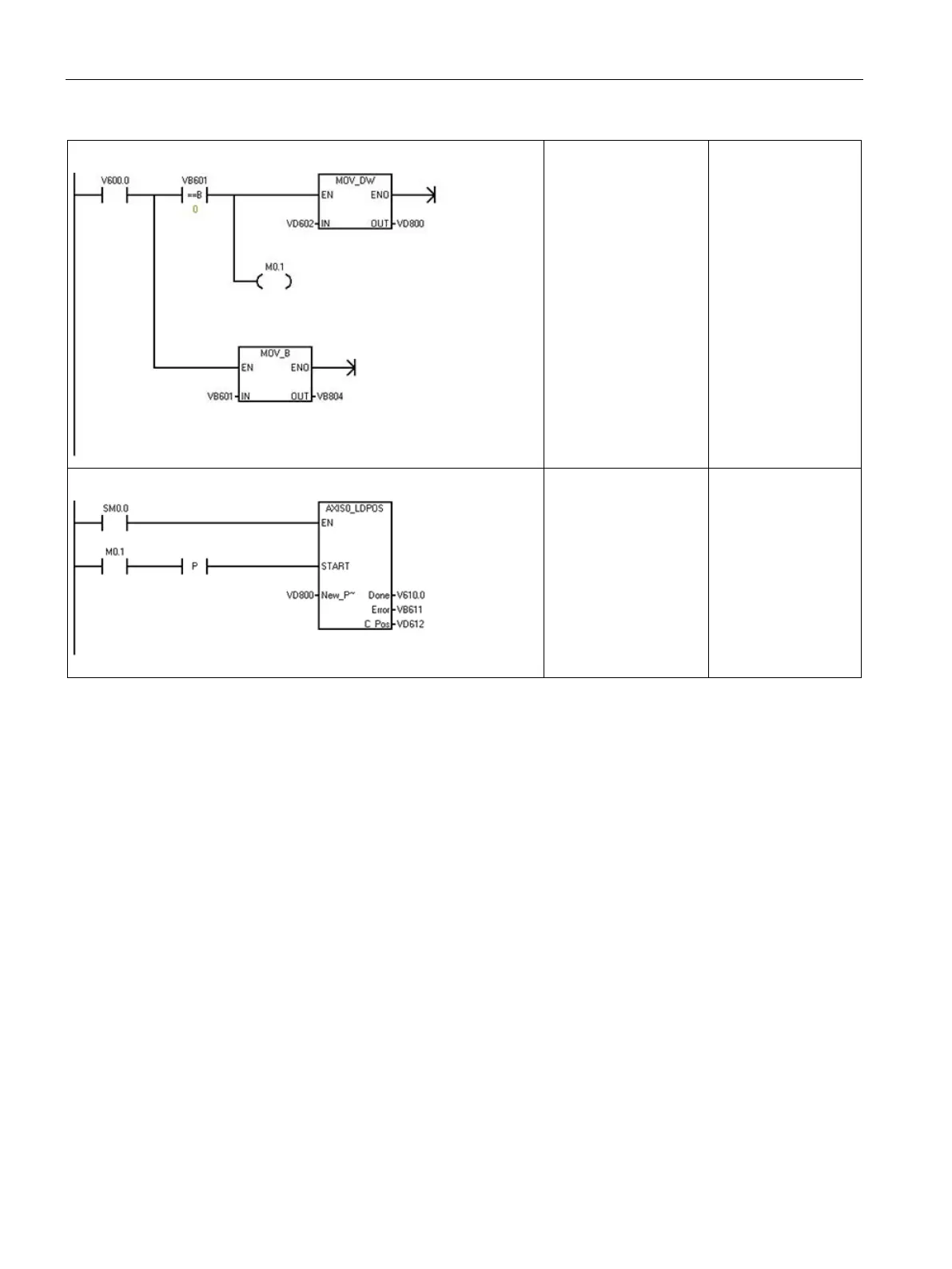

Network 3:

Update the current

position in this Axis of

Motion with the cap-

tured servo position

value.

CALL AXIS0_LDPOS,

L63.7, VD800,

V610.0, VB611,

VD612

Interconnections

Digital I/O

Refer to the section "Connection examples with PLCs" in the

SINAMICS V90 /

SIMOTICS S-1FL6 Operating Instructions

document to find wiring diagrams for connection of

the suggested digital control signals between an S7-200 SMART CPU and a V90 servo

drive.

The AXISx_ABSPOS subroutine obtains the position data from the drive using serial

communications on the RS485 link between the two devices. Therefore, connect a cable

between the RS485 port on the S7-200 SMART CPU (or optionally the S7-200 SMART

CM01 signal board) and the RS485 port on the V90 servo drive.

Refer to the appropriate sections of the

S7-200 SMART System Manual

and the

SINAMICS V90 / SIMOTICS S-1FL6 Operating Instructions

documents for descriptions of

the RS485 ports on the S7-200 SMART CPU and V90 servo drive.

Loading...

Loading...