Program instructions

7.7 Pulse output

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

249

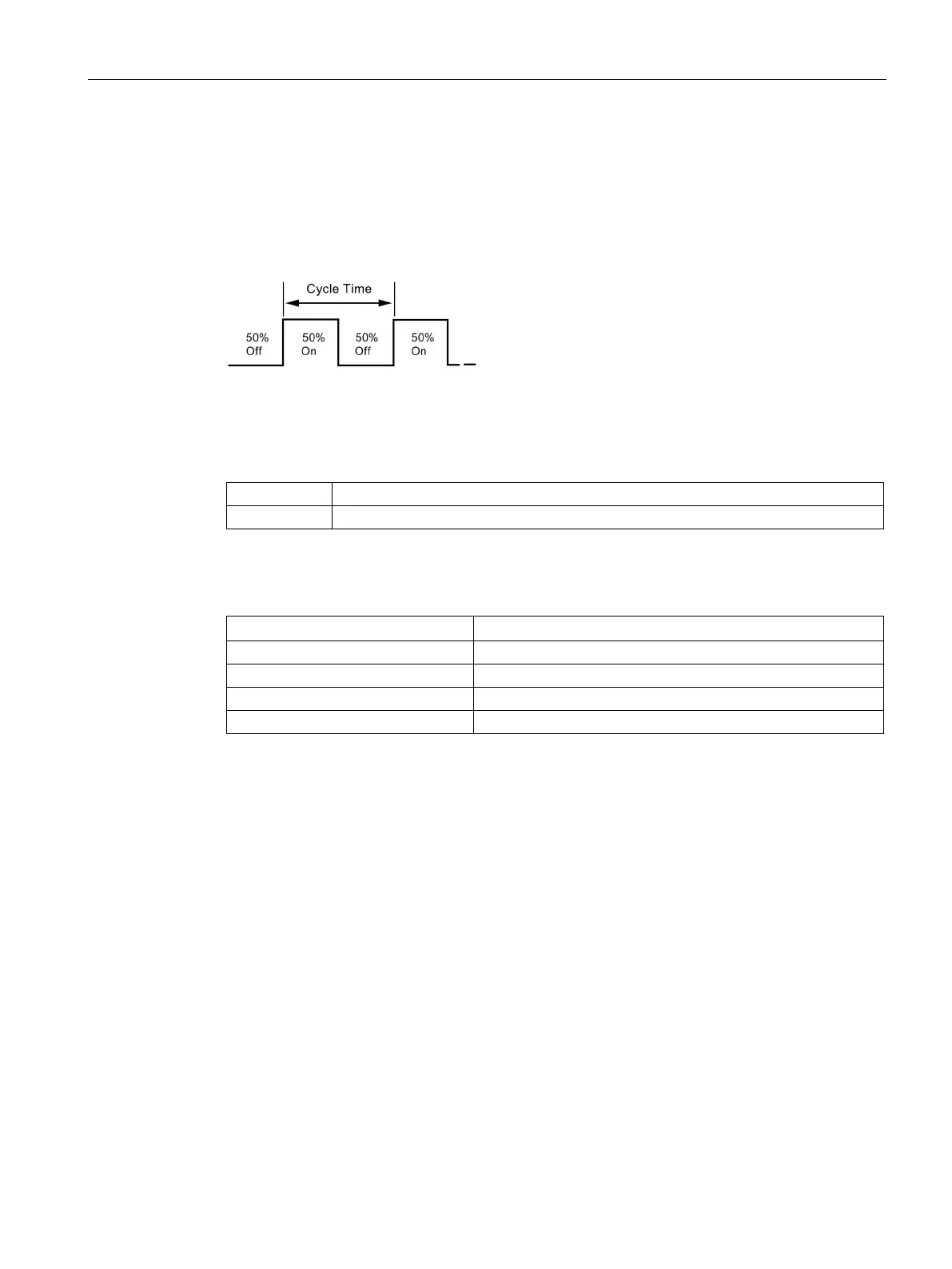

PTO provides a square wave with a 50% duty cycle output for a specified number of pulses

at a specified frequency. Refer to the figure below. PTO can produce either a single train of

pulses or multiple trains of pulses using a pulse profile. You specify the number of pulses

and the frequency:

Number of pulses: 1 to 2,147,483,647

Frequency:

– 1 to 100,000 Hz (multiple-segment)

– 1 to 65,535 Hz (single-segment)

Use the following formula to convert from cycle time to frequency:

where:

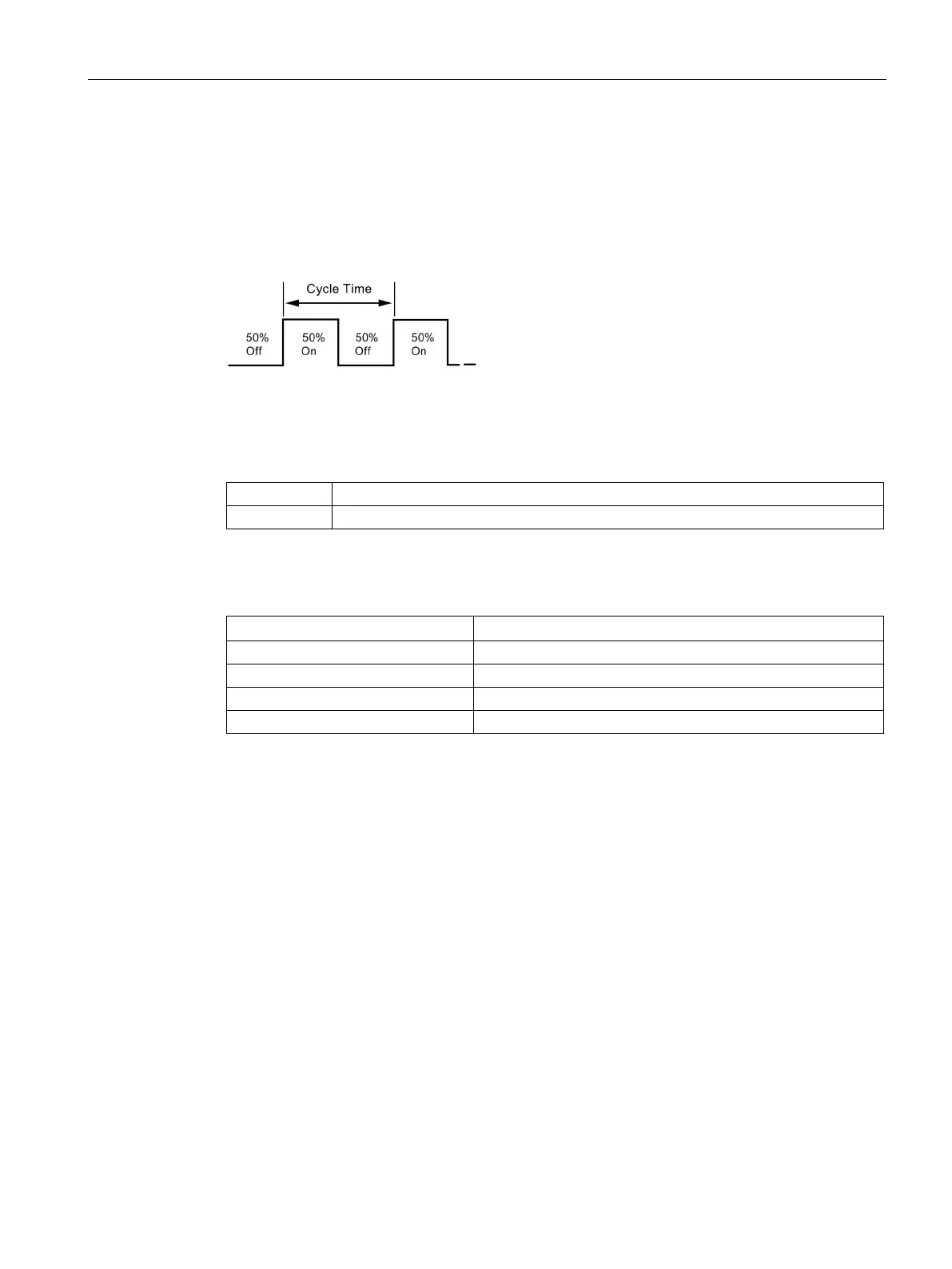

See the following table for pulse count and frequency limitations:

Table 7- 8 Pulse count and frequency in the PTO function

Frequency defaults to 1 Hz

Frequency defaults to 100,000 Hz

Pulse count defaults to 1 pulse

Pulse count > 2,147,483,647

Pulse count defaults to 2,147,483,647 pulses

The PTO function allows the "chaining" or "pipelining" of pulse trains. When the active pulse

train is complete, the output of a new pulse train begins immediately. This allows continuity

between subsequent output pulse trains.

Single-Segment pipelining of PTO pulses

In single-segment pipelining, you are responsible for updating the SM locations for the next

pulse train. After the initial PTO segment has started, you must immediately modify the SM

locations with the parameters of the second waveform. After you update the SM values,

execute the PLS instruction again. The PTO function holds the attributes of the second pulse

train in a pipeline until it completes the first pulse train. The PTO function can store only one

entry at a time in the pipeline. When the first pulse train completes, the output of the second

waveform begins, and you can store a new pulse train specification in the pipeline. You can

then repeat this process to set up the characteristics of the next pulse train. Attempting to

load the pipeline while it is still full results in the PTO Overflow bit (SM66.6, SM76.6, or

SM566.6) being set and the instruction being ignored.

Loading...

Loading...