PID loops and tuning

11.5 Exception conditions

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

475

Exception conditions

Warning conditions

Tuning execution can generate three warning conditions. Tuning execution reports these

warnings in three bits of the ASTAT field of the loop table, and, once set, these bits remain

set until the next auto-tune sequence is initiated:

● Warning 0: Generated if the deviation value is not at least 4X greater than the hysteresis

value. This check is performed when the hysteresis value is actually known, which

depends upon the auto-hysteresis setting.

● Warning 1: Generated if there is more than an 8X difference between the two peak error

values gathered during the first 2.5 cycles of the auto-tune procedure

● Warning 2: Generated if the measured average peak error is not at least 4X greater than

the hysteresis value

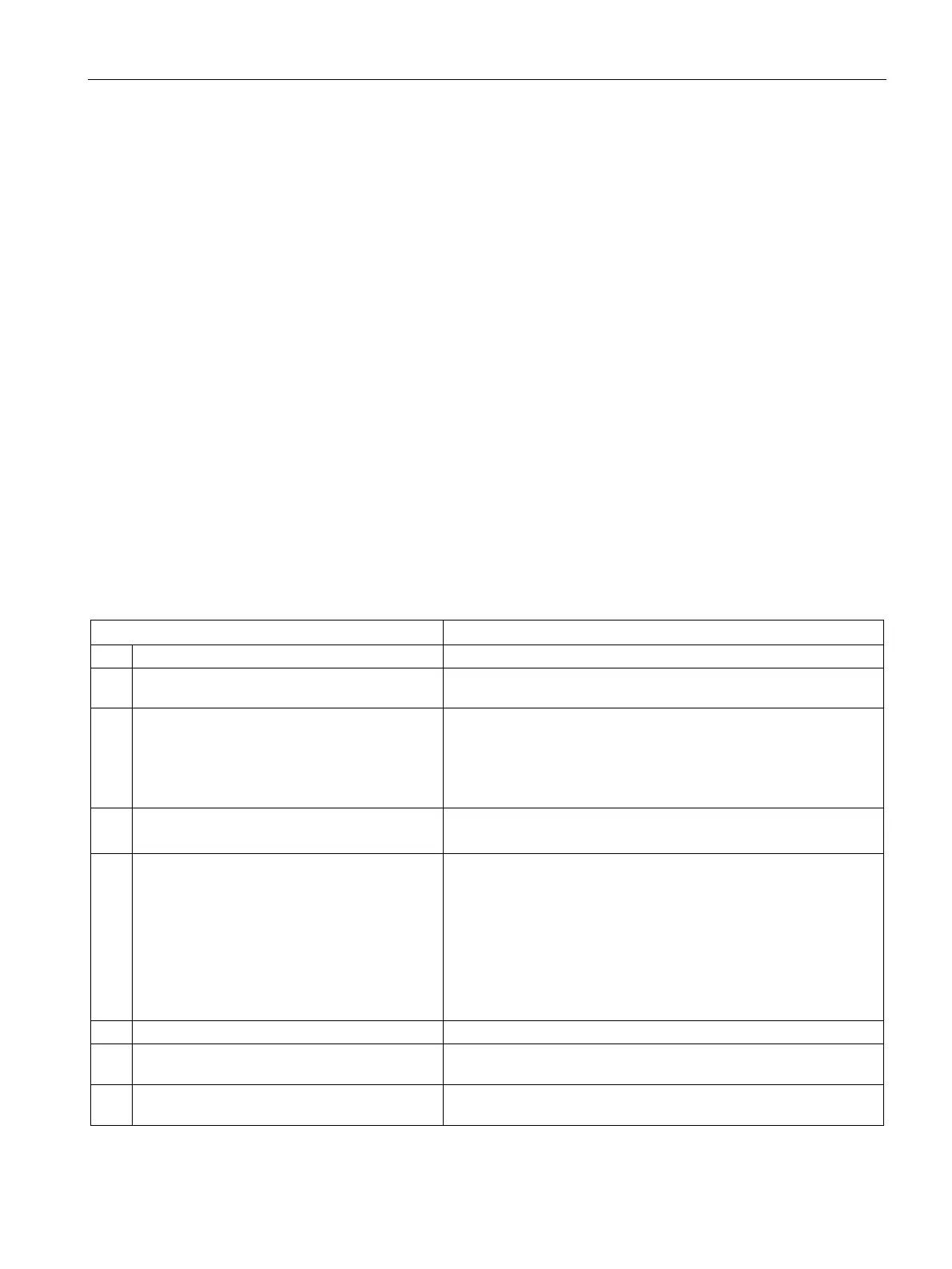

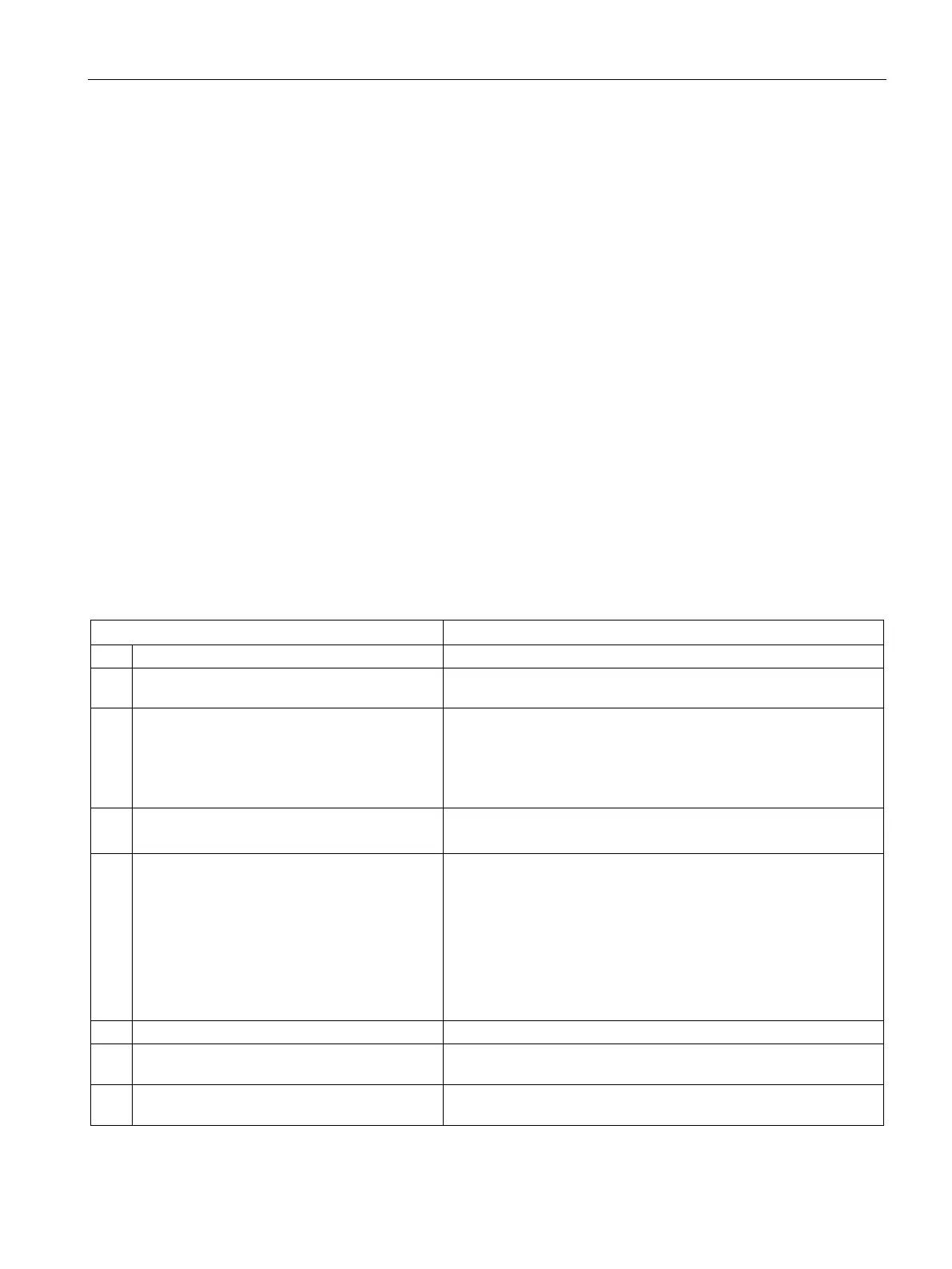

In addition to the warning conditions, several error conditions are possible. The following

table lists the error conditions, along with a description of the cause of each error.

Table 11- 3 Error conditions during tuning execution

EN bit cleared while tuning is in progress

02 aborted due to a zero-crossing watchdog

timeout

Half-cycle elapsed time exceeds zero-crossing watchdog interval

03 aborted due to the process out-of-range PV goes out-of-range:

• during the auto-hysteresis sequence, or

• twice before the fourth zero-crossing, or

• after the fourth zero crossing

04 aborted due to hysteresis value exceeding

maximum

User-specified hysteresis value, or

automatically determined hysteresis value > maximum

05 aborted due to illegal configuration value The following range checking errors:

• Initial loop output value is < 0.0 or > 1.0

• User-specified deviation value is <= hysteresis value, or is >

maximum

• Initial output step is <= 0.0 or is > maximum

• Zero-crossing watchdog interval time is < minimum

• Sample time value in loop table is negative

aborted due to a numeric error

Illegal floating point number or divide by zero encountered

07 PID instruction was executed with no power

PID instruction executed with no power flow while auto-tuning is in

08 auto-tuning allowed only for P, PI, PD, or PID

Loop type is not P, PI, PD, or PID

Loading...

Loading...