Debugging and troubleshooting

10.7 Hardware troubleshooting guide

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

465

Overview of debugging and monitoring features (Page 453)

How to display status in the editor windows (Page 456)

How to display status in a status chart (Page 460)

How to download a program (Page 75)

Timestamp mismatch error (Page 663) (ensuring that project in programming device

matches project in PLC)

Cross reference and element usage (Page 454) (ensuring that program edits do not cause

duplicate assignments)

Forcing values (Page 462)

Forcing outputs in STOP mode (Page 463)

Hardware troubleshooting guide

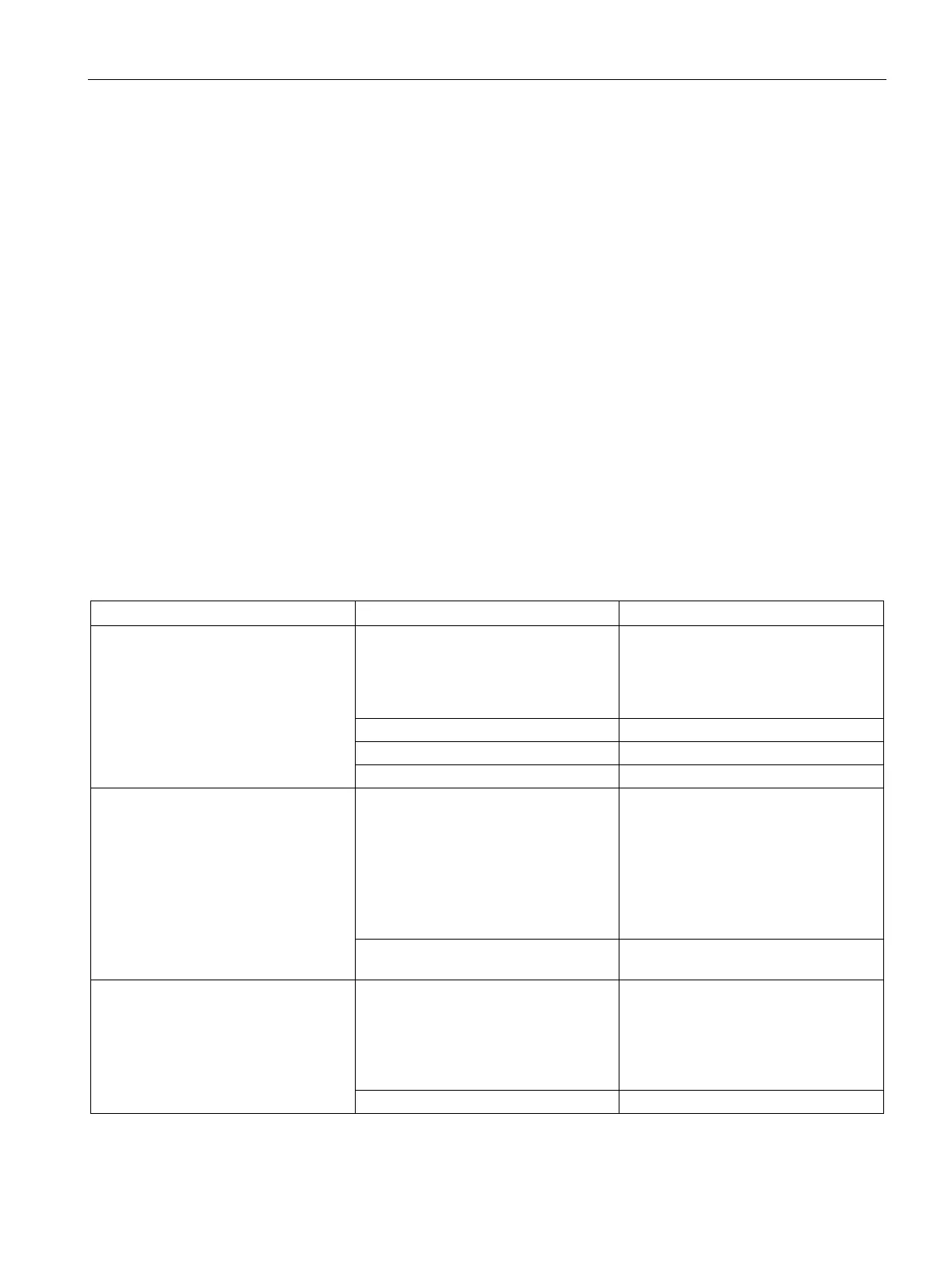

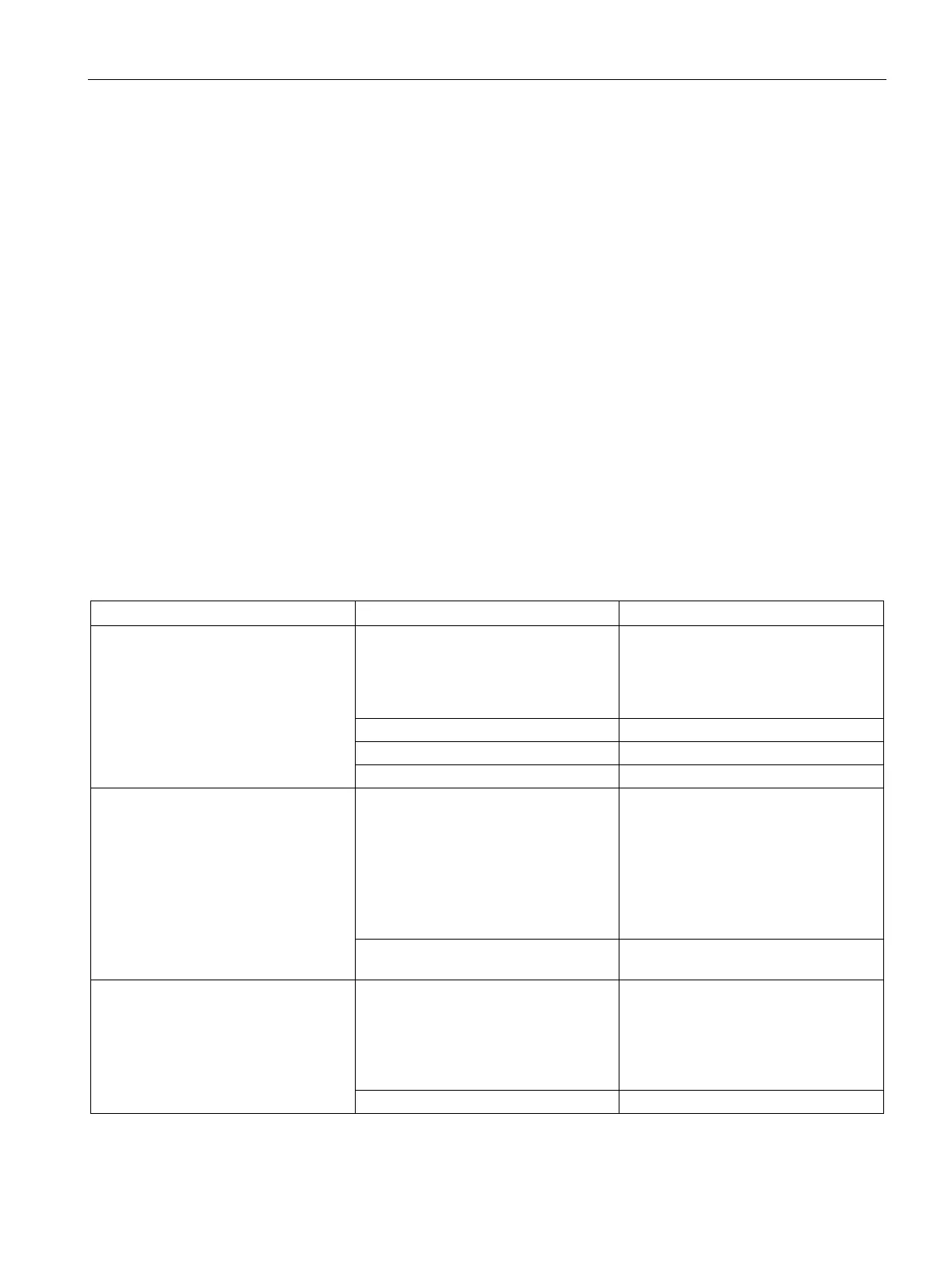

Table 10- 1 Troubleshooting guide for the S7-200 SMART hardware

Outputs stop working The device being controlled has

caused an electrical surge that dam-

aged the output

When connecting to an inductive load

(such as a motor or relay), a proper

suppression circuit should be used.

Refer to

the wiring guidelines in Chap-

Wiring loose or incorrect

Check load against contact ratings

Check the CPU for forced I/O

ERROR light on the CPU turns on

(Red)

Electrical noise Refer to

the wiring guidelines in Chap-

ter 3. It is very important that the con-

trol panel is connected to a good

ground and that high voltage wiring is

not run in parallel with low voltage

wiring.

Connect the M terminal on the 24 V DC

Sensor Power Supply to ground

Component damage Send in hardware for repair or re-

None of the CPU LEDs turn on Blown fuse Use a line analyzer and monitor the

input power to check the magnitude

and duration of the over-voltage spikes.

Based on this information, add the

proper type surge arrestor device to

your power wiring.

Reversed 24 V power wires

Refer to the wiring guidelines in Chap-

Loading...

Loading...