Open loop motion control

12.6 Subroutines created by the Motion wizard for the Axis of Motion

S7-200 SMART

508 System Manual, 09/2015, A5E03822230-AC

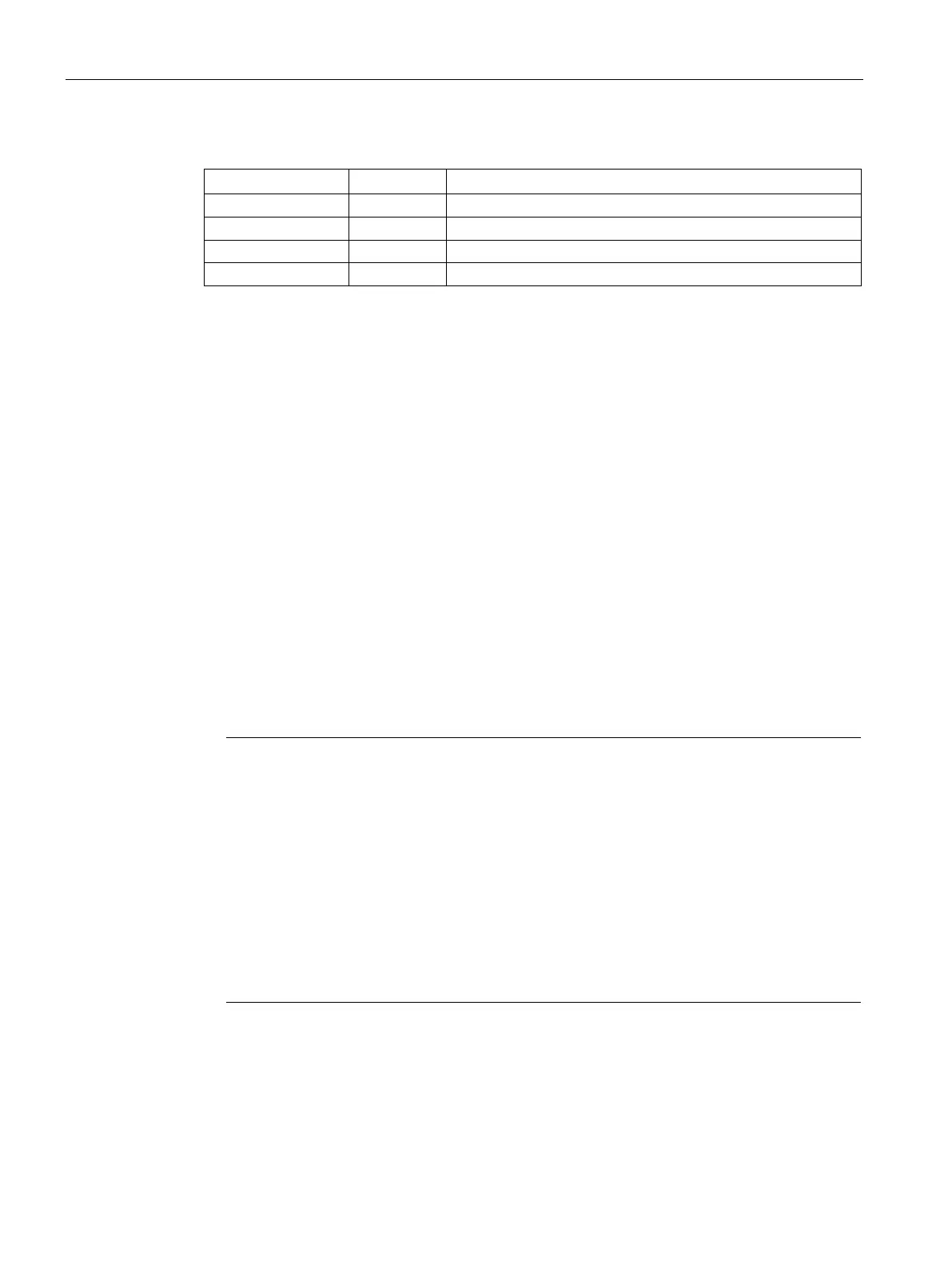

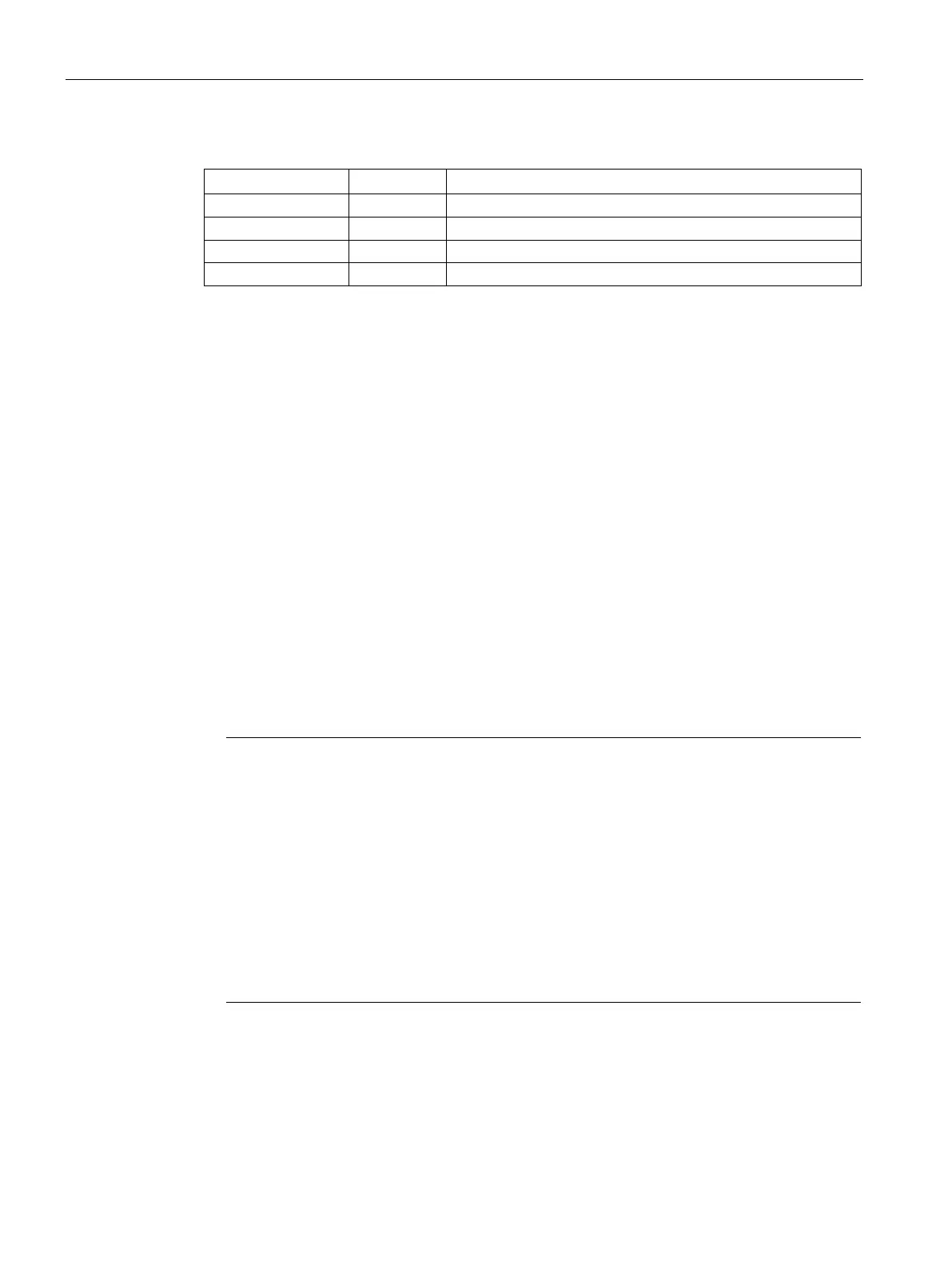

Table 12- 7 Parameters for the AXISx_CTRL subroutine

I, Q, V, M, SM, S, T, C, L, Power Flow

Done, C_Dir BOOL I, Q, V, M, SM, S, T, C, L

IB, QB, VB, MB, SMB, SB, LB, AC, *VD, *AC, *LD

C_Pos, C_Speed DINT, REAL ID, QD, VD, MD, SMD, SD, LD, AC, *VD, *AC, *LD

The MOD_EN parameter must be on to enable the other motion subroutines to send

commands to the Axis of Motion. If the MOD_EN parameter turns off, then the Axis of Motion

aborts any command that is in progress and performs a decelerated stop.

The output parameters of the AXISx_CTRL subroutine provide the current status of the Axis

of Motion.

The Done parameter turns on when the Axis of Motion completes any subroutine.

The Error parameter (Page 545) contains the result of this subroutine.

The C_Pos parameter is the current position of the Axis of Motion. Based upon the units of

measurement, the value is either a number of pulses (DINT) or the number of engineering

units (REAL).

The C_Speed parameter provides the current speed of the Axis of Motion. If you configured

the measurement system for the Axis of Motion for pulses, C_Speed is a DINT value

containing the number of pulses/second. If you configured the measurement system for

engineering units, C_Speed is a REAL value containing the selected engineering

units/second (REAL).

The C_Dir parameter indicates the current direction of the motor:

● Signal state of 0 = positive

● Signal state of 1 = negative

Note

The Axis of Motion reads the configuration/profile table only at power

-up or when

commanded to load the configuration.

If you use the Motion wizard to modify the configuration, then the AXISx_CTRL

subroutine automatically commands the Axis of Motion to load the configuration/profile

table every time the CPU changes to RUN mode.

If you use the Motion control panel to modify the configuration, clicking the Update

Configuration button commands the Axis of Motion to load the new

configuration/profile table.

If you use another method to modify the configuration, then you must also issue an

AXISx_CFG command to the Axis of Motion to load the configuration/profile table.

Otherwise, the Axis of Motion continues to use the old configuration/profile table.

Loading...

Loading...