Installation

3.4 Wiring guidelines

S7-200 SMART

52 System Manual, 09/2015, A5E03822230-AC

Guidelines for inductive loads

You should equip inductive loads with suppression circuits to limit voltage rise when the

control output turns off. Suppression circuits protect your outputs from premature failure due

to the high voltages associated with turning off inductive loads. In addition, suppression

circuits limit the electrical noise generated when switching inductive loads. Placing an

external suppression circuit so that it is electrically across the load, and physically located

near the load is most effective in reducing electrical noise.

The DC (transistor) outputs include internal suppression circuits that are adequate for the

inductive loads in most applications. Since the relay output contacts can be used to switch

either a DC or an AC load, internal protection is not provided.

effectiveness of a given suppression circuit depends on the application, and you must

verify it for your particular use. Always ensure that all components used in your suppression

circuit are rated for use in the application.

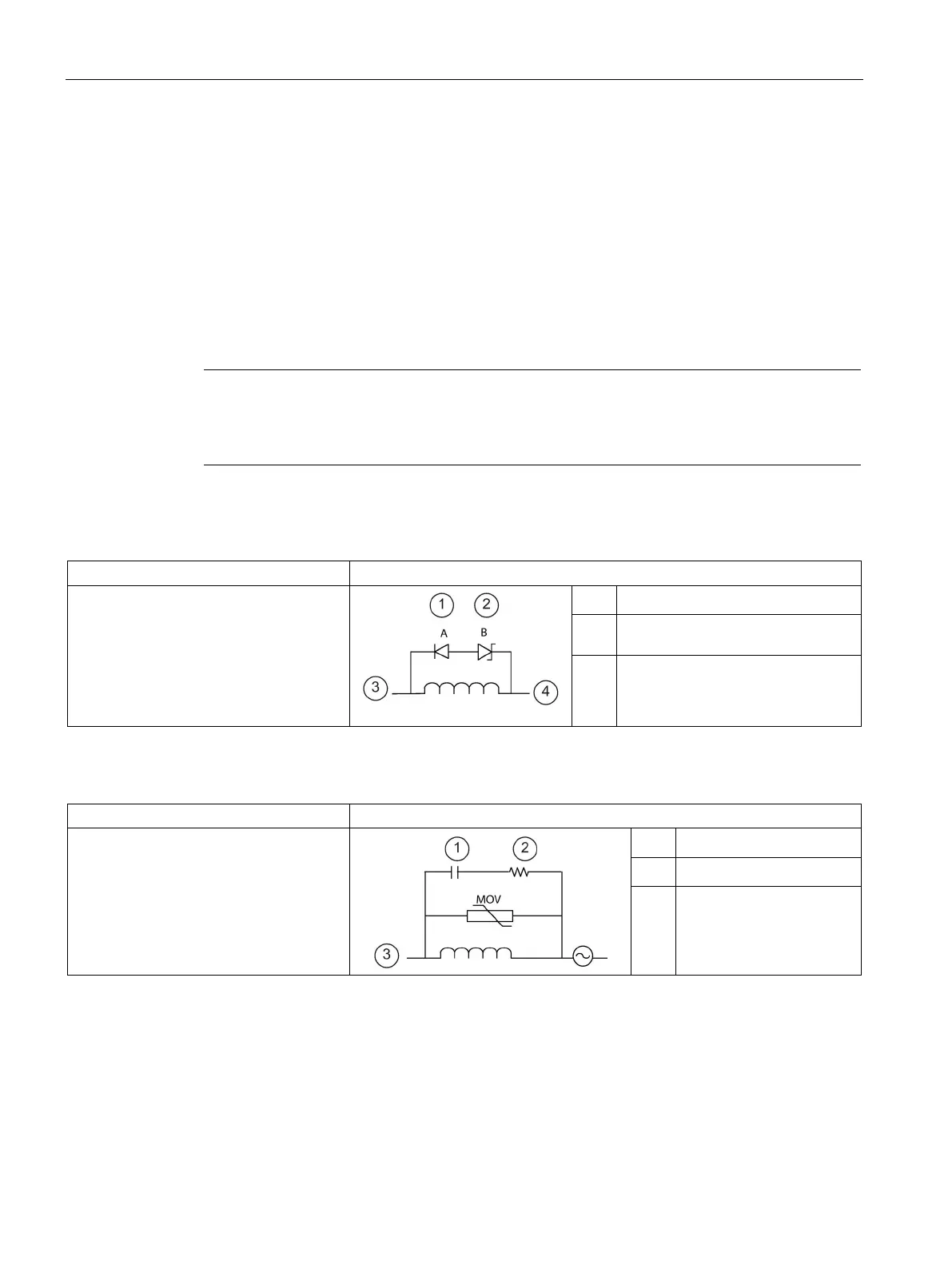

Table 3- 9 Typical suppressor circuit for DC or relay outputs that switch DC inductive loads

In most applications, the addition of a

diode ① across a DC inductive load is

suitable, but if your application requires

faster turn-off times, then the addition of a

Zener diode

② is recommended. Be sure

to size your Zener diode properly for the

amount of current in your output circuit.

1N4001 diode or equivalent

8.2 V Zener (DC outputs),

36 V Zener (Relay outputs)

③

Output point

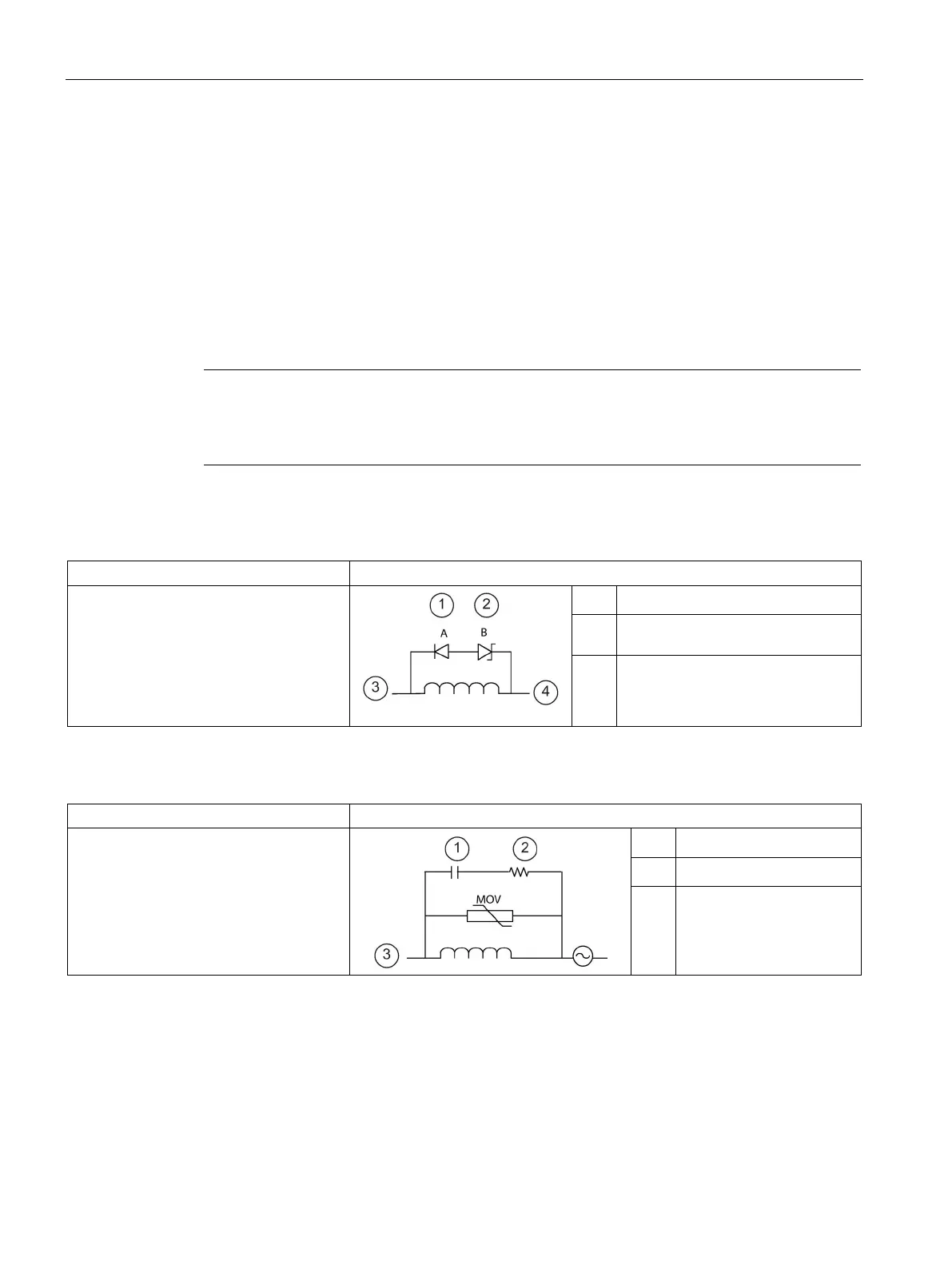

Table 3- 10 Typical suppressor circuit for relay outputs that switch AC inductive loads

When you use a relay output to switch

115 V/230 V AC loads, place the appro-

priately rated resistor-capacitor-metal

oxide varistor (MOV) circuit across the AC

load. Ensure that the working voltage of

the MOV is at least 20% greater than the

nominal line voltage.

0.1 μ F

100 to 120 Ω

③

Output point

Loading...

Loading...