Open loop motion control

12.7 Using the AXISx_ABSPOS subroutine to read the absolute position from a SINAMICS servo drive

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

527

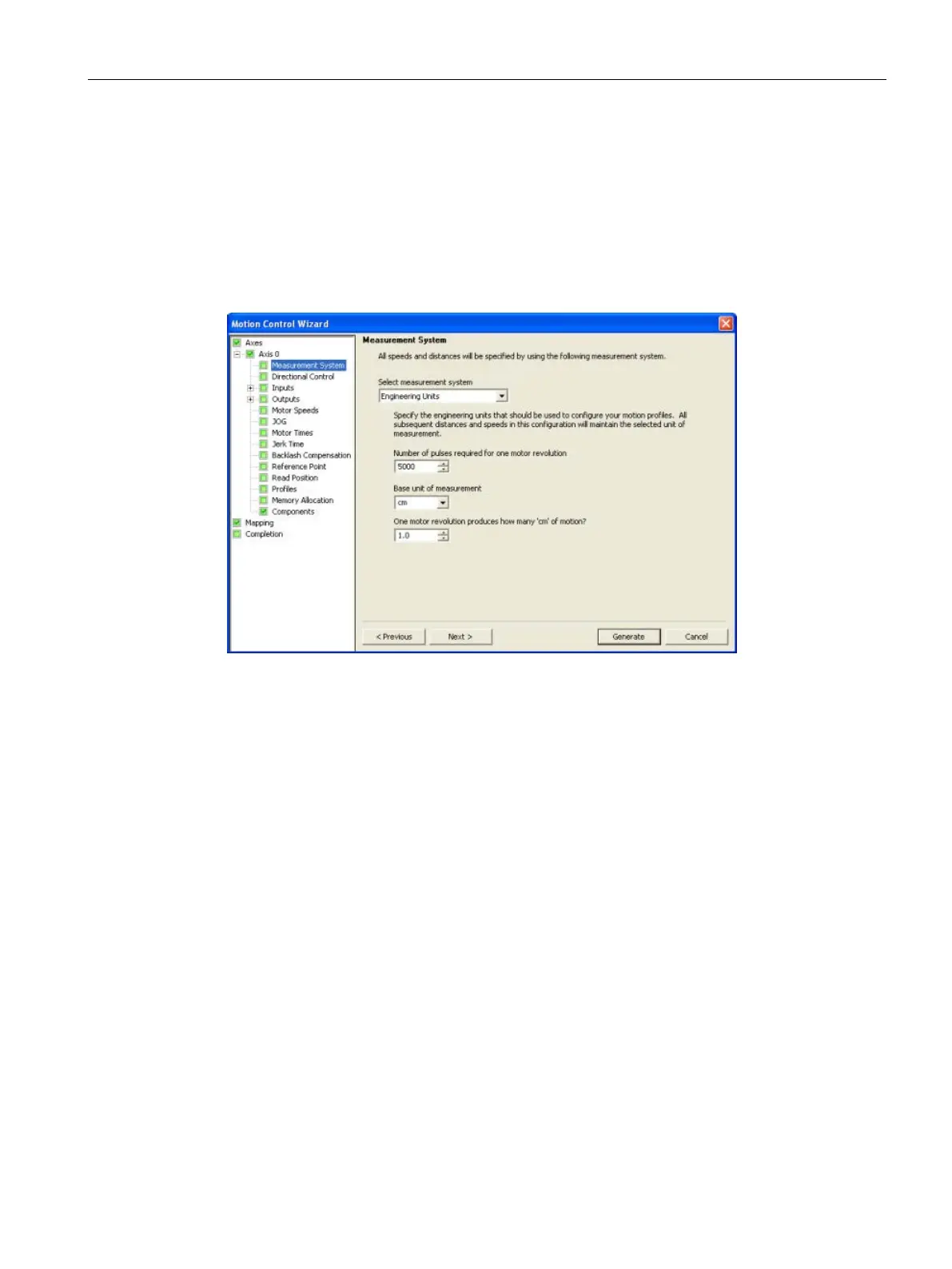

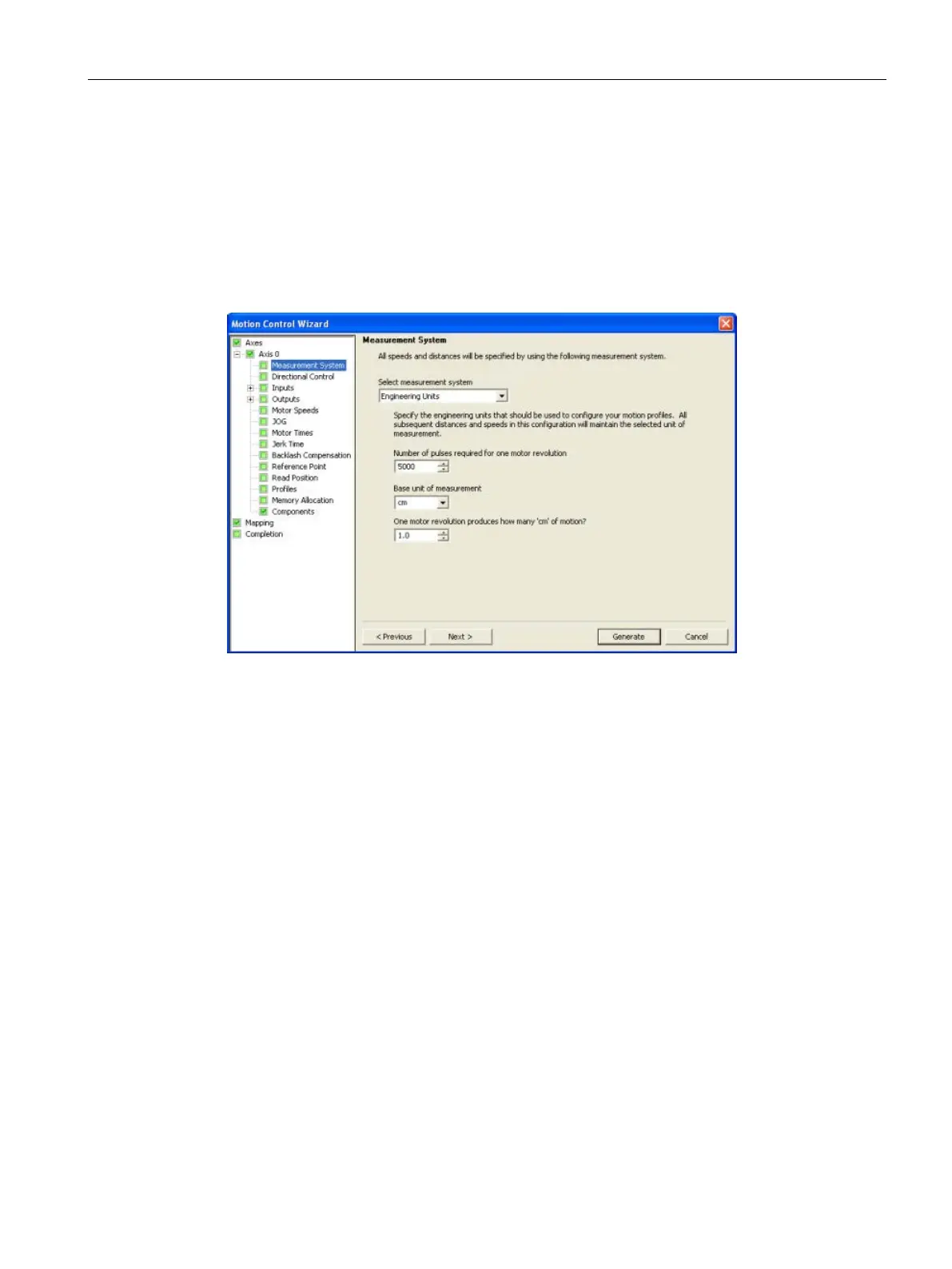

Measurement system settings in the Motion wizard

When using the STEP 7-Micro/WIN SMART Motion wizard to configure the measurement

system for a CPU Axis of Motion, you must assign the three conversion settings:

● First setting: Relates CPU pulses to motor revolutions

● Second setting: Establishes the base engineering unit name

● Third setting: Relates motor revolutions to load movement

Setting 1: "Number of pulses required for one motor revolution"

This setting defines the relationship between CPU pulses and motor revolutions. The

relevant equation that yields the correct value for this setting follows:

(1) Number of pulses required for one motor revolution = r * (b / a)

where, "r" = encoder resolution, expressed as encoder pulses per motor revolution,

"a" and "b" = electronic gearing (E-gear) ratio parameters ("a" = value of V90 parameter

"p29012[0]" and "b" = value of V90 parameter "p29013")

For example, if the desired E-gear ratio is "128:1" and the motor’s absolute encoder

resolution is 2^20 or "1048576", then:

"Number of pulses required for one motor revolution" =

1048576 * (1 / 128) = 8192

Setting 2: "Base unit of measurement"

This setting establishes the base engineering unit name for speed and distance settings

throughout the Motion wizard. To avoid confusion, the selection should match the

engineering unit relevant at the load. For example, if load movement and speed is to be

expressed in "cm" and "cm / second", then the "cm" selection should be chosen for this

setting.

Loading...

Loading...