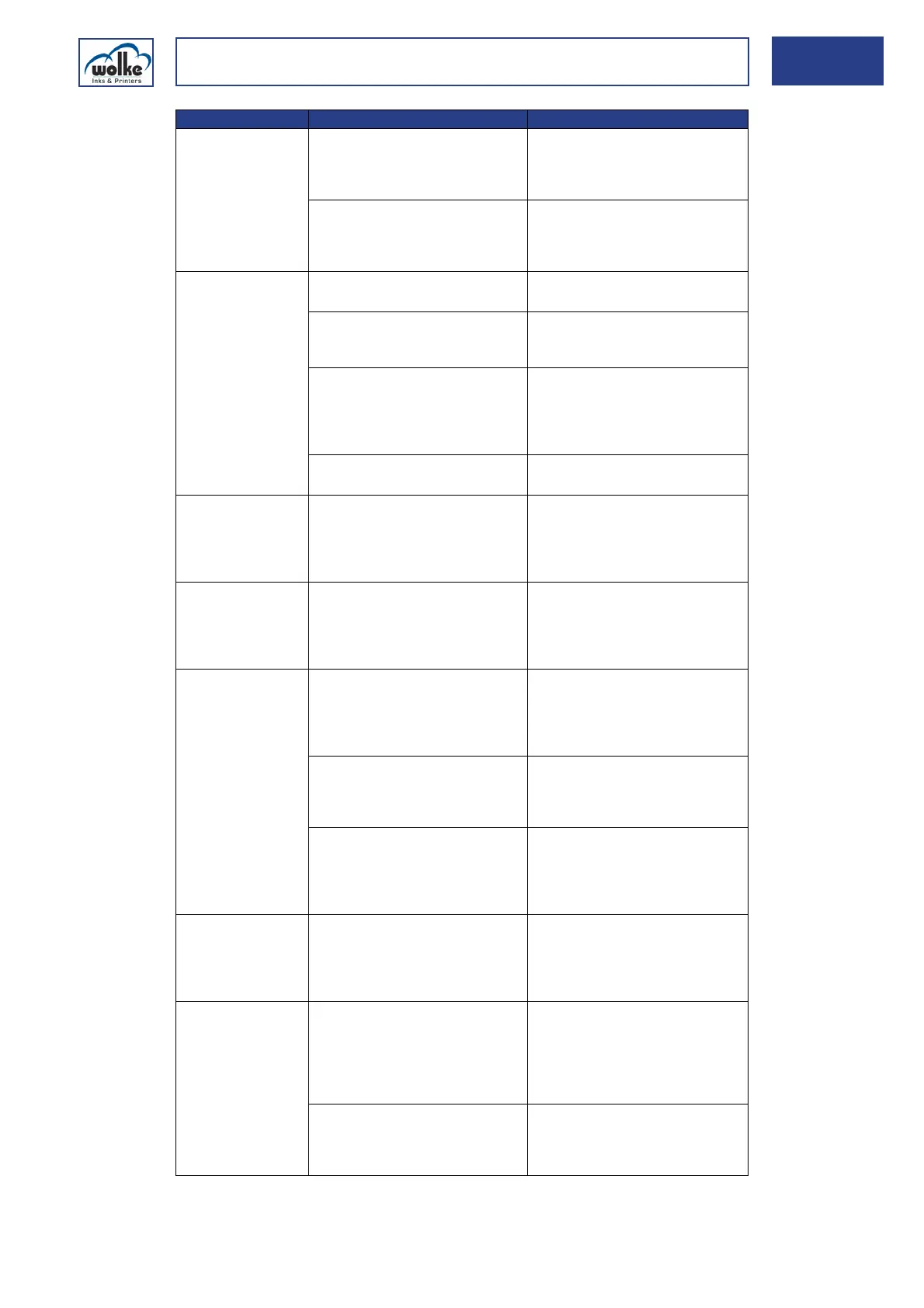

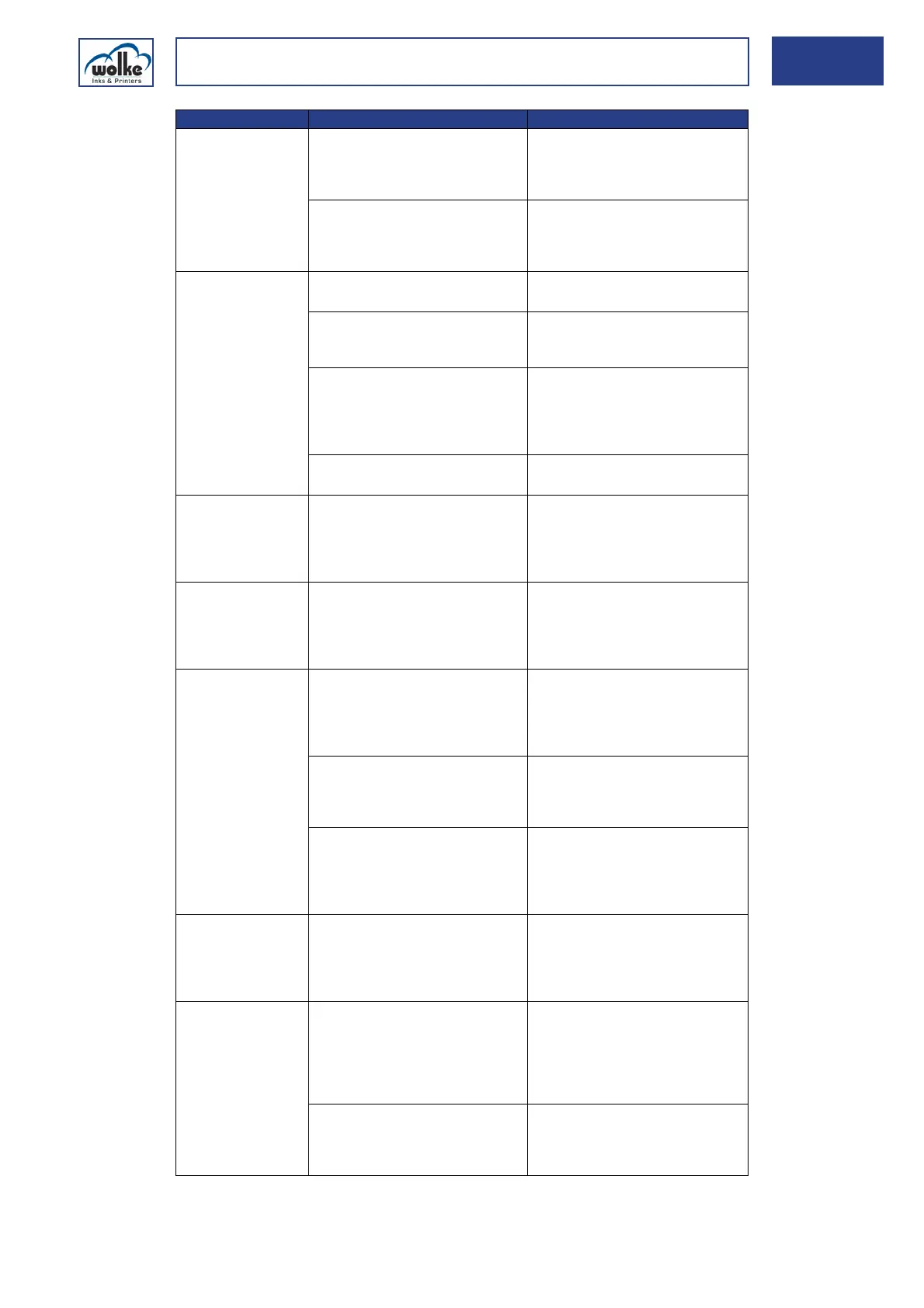

FAQ

Manual m600 basic 2.6_01 183

18

Shadow print The measuring wheel of the shaft

encoder does not run parallel to

the belt. This results in excessive

slippage and a false speed signal.

Set the direction of running of the

measuring wheel to be parallel to

the belt.

Prints are made without the shaft

encoder. The product speed set in

the system settings is different to

the actual product speed.

Please check the actual product

speed and adjust accordingly.

Stretched or

compressed print

image

The pulse count per meter is in-

correct.

Adjust the pulse count per meter.

The shaft encoder measuring

wheel measures the speed on a

curve (e.g. guide roller).

Mount the measuring wheel on a

flat surface as far as possible.

Prints are made without the shaft

encoder. The fixed product speed

set in the system settings is either

too fast (compressed) or too slow

(stretched).

Set the exact speed in the system

settings menu.

The resolution setting referring to

the speed is too high.

Reduce the resolution or the

delivery rate!

The print image is

printed upside

down

The position setting has been

incorrectly set in the plant

settings for the appropriate print

head.

Check the plant settings for the

print head in question and, if

applicable, change them! Please

also observe the specifications in

Chapter 6.2.4.

The print image is

back-to-front

The "mirrored" setting has been

incorrectly set in the plant

settings for the appropriate print

head.

Check the plant settings of the

print head in question and, if

applicable, change them! Please

also observe the specifications in

Chapter 6.2.4.

The print position

is incorrect

The sensor distance is incorrect. Measure the actual values and

adjust the setting. Please also

observe the specifications in

Chapter 6.2.4 and Chapter

6.2.4.1.

The "Distance before" value in the

label settings is incorrect.

Measure the actual values and

adjust the setting. Please also

observe the specifications in

Chapter 7.5.

The product does not pass the

sensor on the belt with a uniform

alignment. The misalignment of

the product causes the print to

trigger too early or too late.

Ensure that the products are bet-

ter aligned while being conveyed.

Fit or readjust guide rails if neces-

sary.

Print in block

form or "cubic

graphics"

The products are conveyed at too

fast a speed for the set resolution

(DPI).

Please adjust the value for the

"Resolution (DPI)" accordingly.

Please also observe the

appropriate specifications in

Chapter 7.5.2.

White stripes in

the print image

Some of the nozzles in the car-

tridge may be clogged and re-

quire cleaning.

Please remove the cartridge and

clean the nozzles. It is recom-

mended that you use a microfiber

cloth to clean them. For optimum

cleaning results, dampen the

cloth slightly with distilled water.

Some of the nozzles in the car-

tridge may be faulty as a result of

mechanical damage.

Replace the cartridge with a new

one. Please do not forget to reset

the ink level in the "Change car-

tridge" menu to 100 %.

Fault Cause Solution

Loading...

Loading...