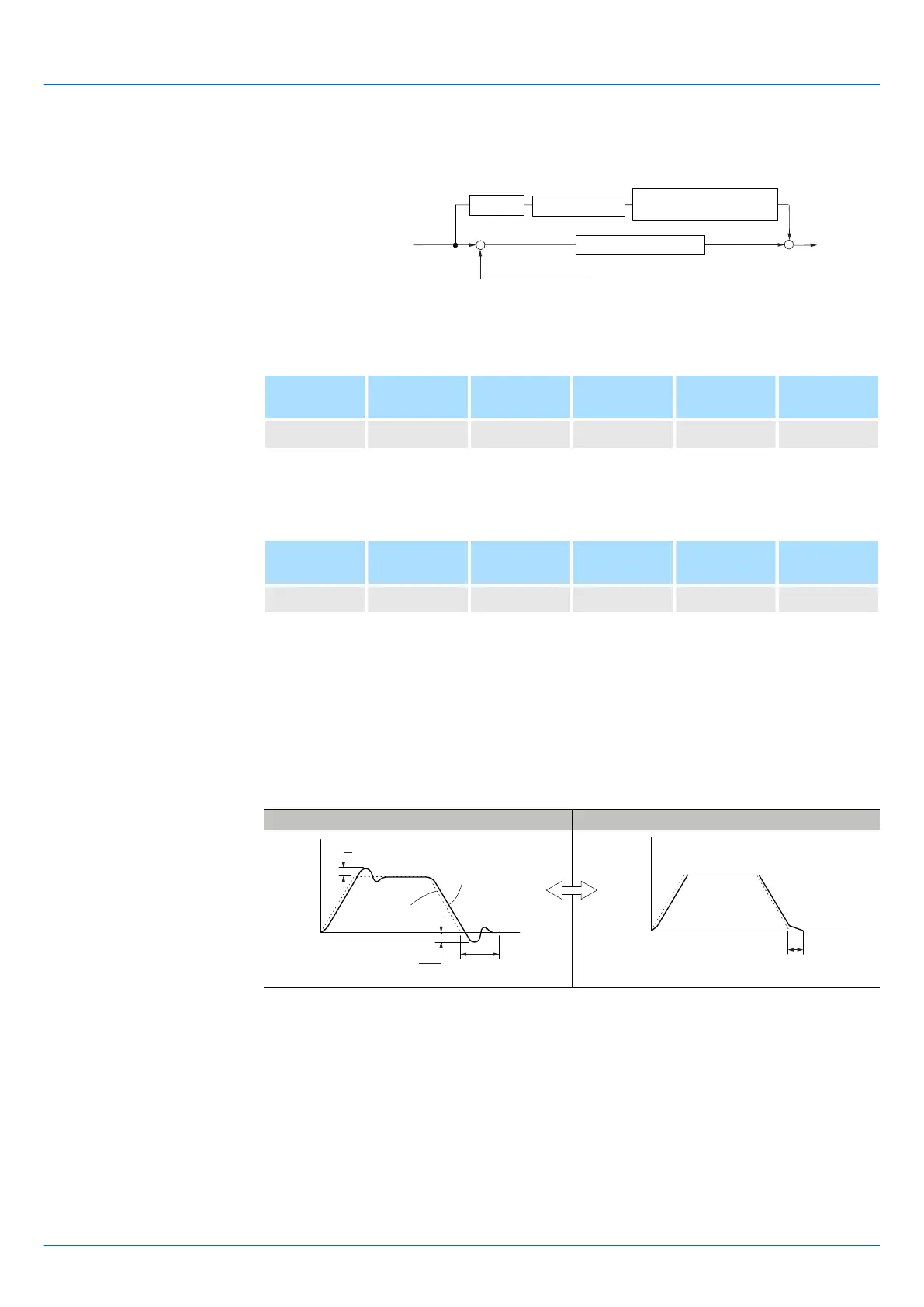

The feedforward function applies feedforward compensation to position control to shorten

the positioning time.

+

+

+

-

Pn109

Pn10A

Position reference pulses

Feedback pulses

Position loop gain (Kp)

Feedforward Filter

Time Constant

FeedforwardDifferential

Fig. 306: Feedforward Function

Feedforward

Setting

Range

Setting Unit Default Set-

ting

When Ena-

bled

Classifica-

tion

Pn109 0 to 100 1% 0 Immediately Tuning

(applies to Position Control)

Feedforward Filter Time Constant

Setting

Range

Setting Unit Default Set-

ting

When Ena-

bled

Classifica-

tion

Pn10A 0 to 6,400 0.01 ms 0 Immediately Tuning

(applies to Position Control)

Note: If you set the feedforward value too high, the machine may vibrate. As a guideline,

use a setting of 80% or less.

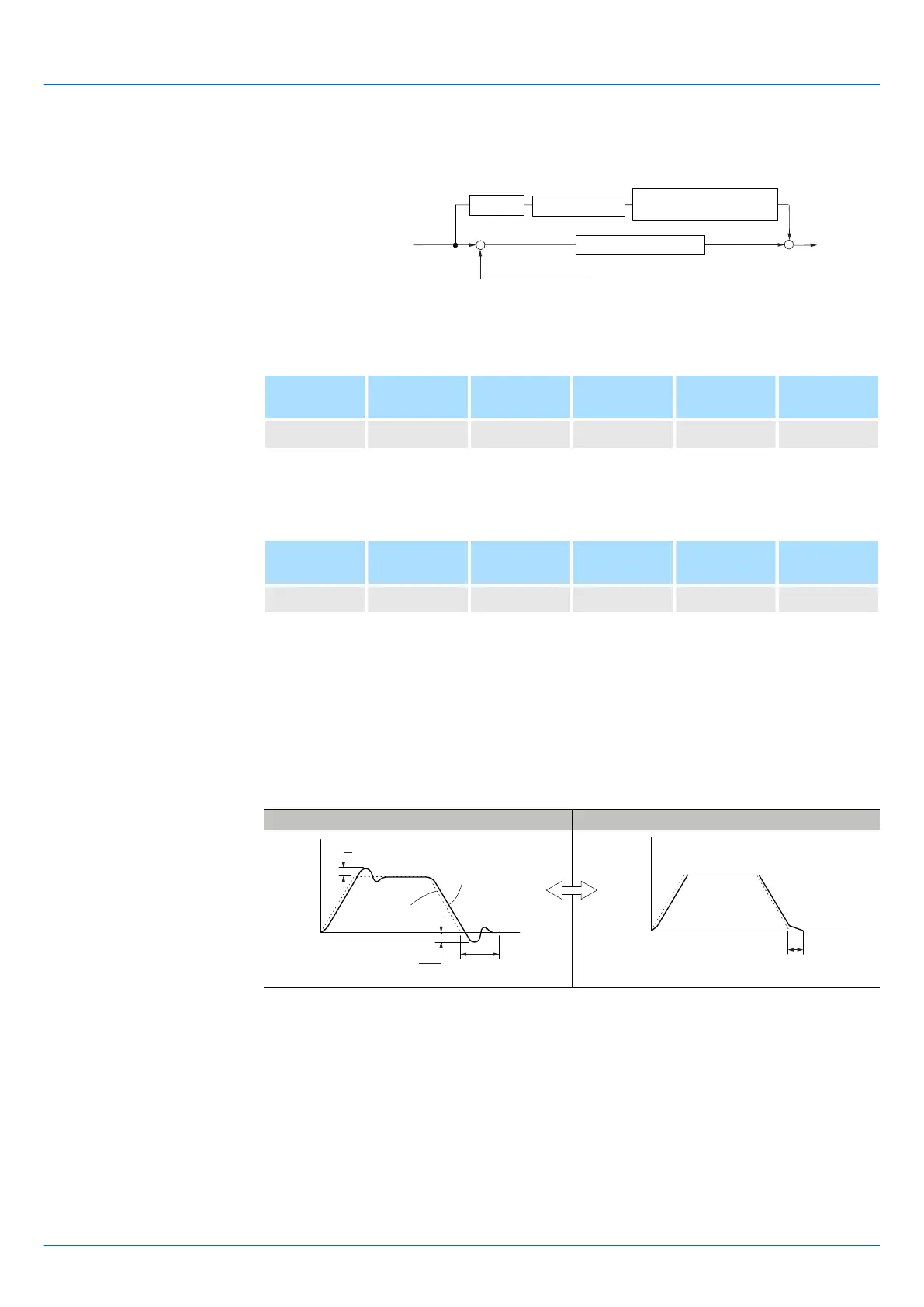

You can use mode switching to automatically change between proportional control and PI

control.

Overshooting caused by acceleration and deceleration can be suppressed and the set-

tling time can be reduced by setting the switching condition and switching levels.

Without Mode Switching With Mode Switching

Motor

speed

Overshooting

Actual Servomotor

operation

Reference

Time

Settling time

Overshooting

Motor

speed

Settling time

Time

Fig. 307: Mode Switching

n Related Parameters

Select the switching condition for mode switching with Pn10B = n.X.

Feedforward

Mode Switching

(Changing between Pro-

portional and PI Control)

Sigma-7 Series SERVOPACKs

Tuning

Manual Tuning > Compatible Adjustment Functions

| | PROFINET Communications - SIEP YEUOC7P 02A Revision 0 | en | 420

Loading...

Loading...