Program instructions

7.9 PID

S7-200 SMART

System Manual, 09/2015, A5E03822230-AC

281

The default state of the PID history bits is "set" and that state is established at startup and on

every STOP-to-RUN mode transition of the controller. If power flows to the PID box the first

time that it is executed after entering RUN mode, then no power-flow transition is detected

and the bumpless mode change actions are not performed.

Alarm checking and special operations

The PID instruction is a simple but powerful instruction that performs the PID calculation. If

other processing is required such as alarm checking or special calculations on loop

variables, these must be implemented using the basic instructions supported by the CPU.

When it is time to compile, the CPU will generate a compile error (range error) and the

compilation will fail if the loop table start address or PID loop number operands specified in

the instruction are out of range.

Certain loop table input values are not range checked by the PID instruction. You must take

care to ensure that the process variable and setpoint (as well as the bias and previous

process variable if used as inputs) are real numbers between 0.0 and 1.0.

If any error is encountered while performing the mathematical operations of the PID

calculation, then SM1.1 (overflow or illegal value) is set and execution of the PID instruction

is terminated. (Update of the output values in the loop table could be incomplete, so you

should disregard these values and correct the input value causing the mathematical error

before the next execution of the loop's PID instruction.)

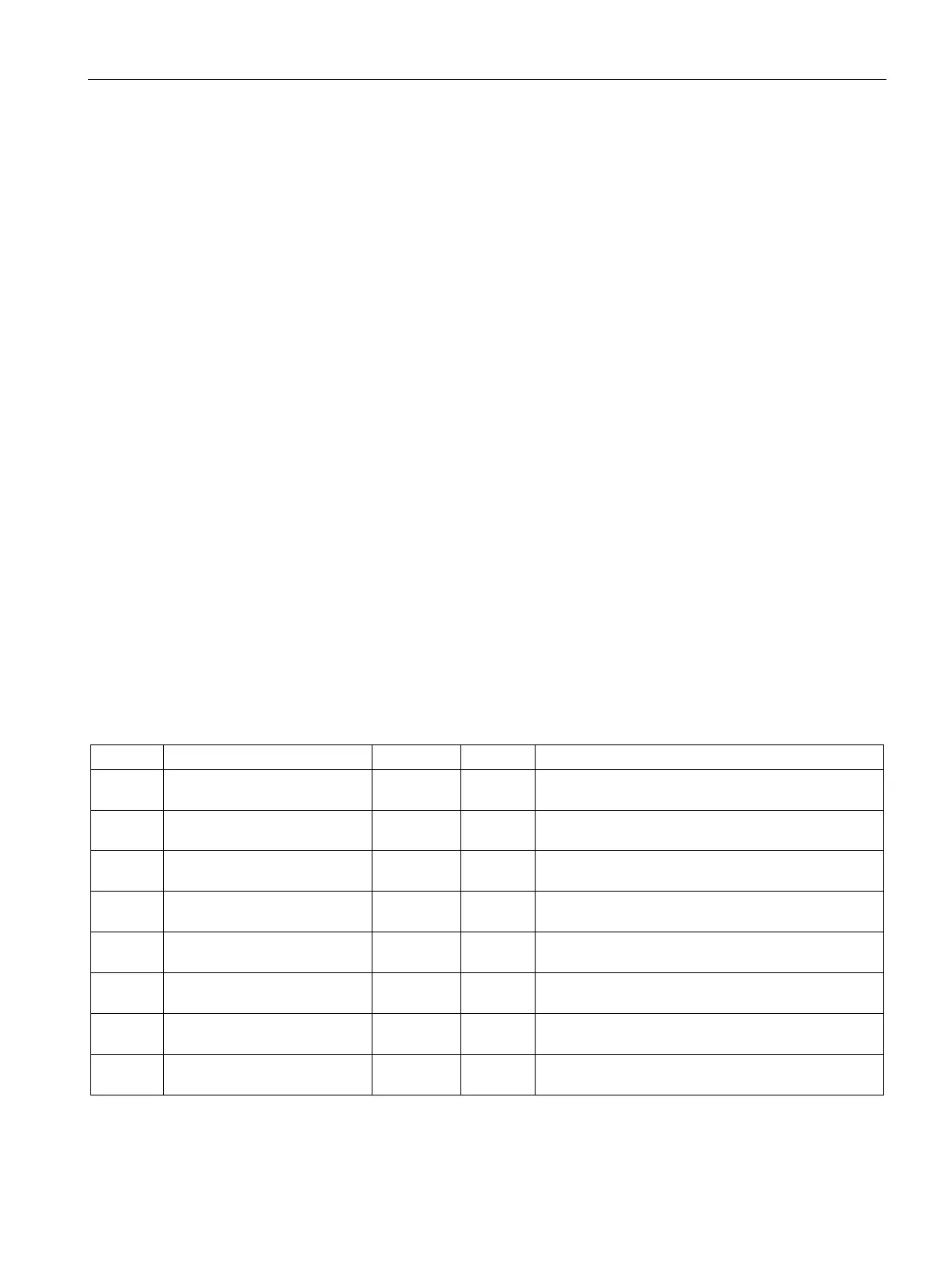

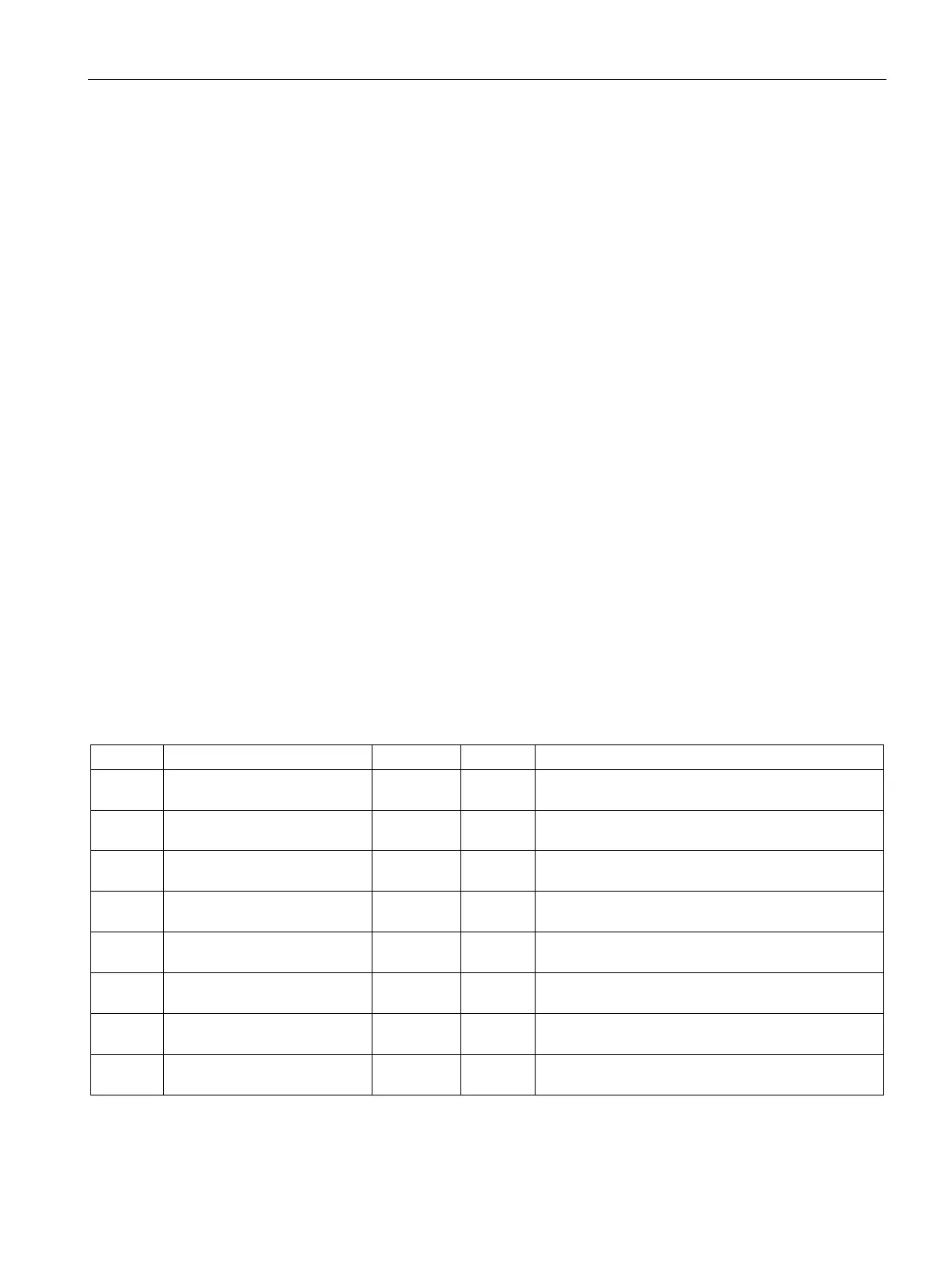

The loop table is 80 bytes long and has the format shown in the following table.

0 Process variable (PV

n

) REAL In Contains the process variable, which must be scaled

4 Setpoint (SP

n

) REAL In Contains the setpoint, which must be scaled be-

tween 0.0 and 1.0.

8 Output (M

n

) REAL In/Out Contains the calculated output, scaled between 0.0

12 Gain (K

C

) REAL In Contains the gain, which is a proportional constant.

Can be a positive or negative number.

16 Sample time (T

S

) REAL In Contains the sample time, in seconds. Must be a

20 Integral time or reset (T

I

) REAL In Contains the integral time or reset, in minutes. Must

24 Derivative time or rate (T

D

) REAL In Contains the derivative time or rate, in minutes. Must

28 Bias (MX) REAL In/Out Contains the bias or integral sum value between 0.0

Loading...

Loading...