Maintenance1112−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 3

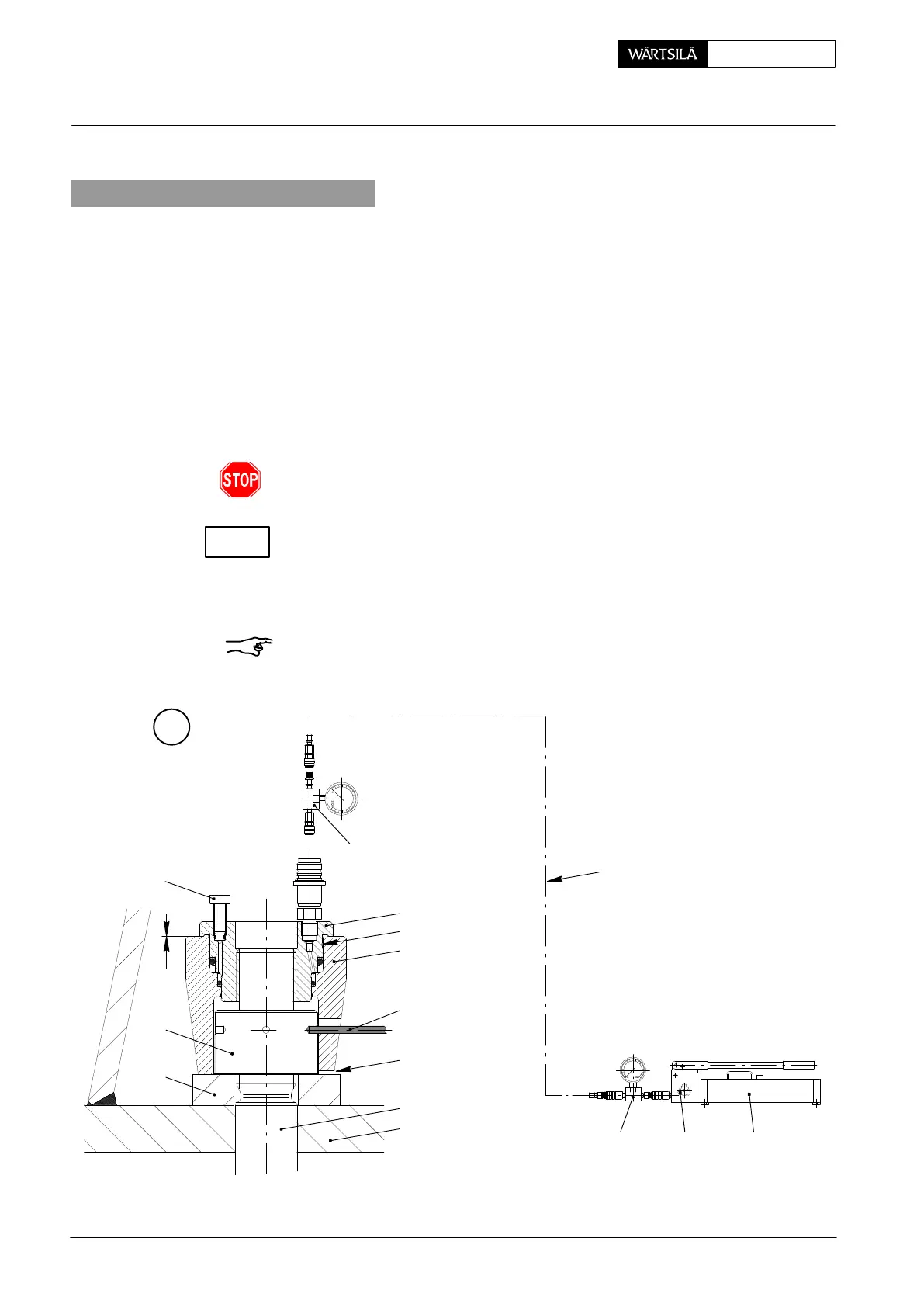

2. Checking the pre-tension

⇒ Clean the threads of the foundation bolts and the seating surfaces. Subse-

quently apply MOLYKOTE G paste to the threads.

⇒ Place pre-tensioning jack 94145 on foundation bolt 6 or fitted stud 7 to be

checked, and screw it completely down with vent screw 1 open until there is

only little or no clearance at ’x’ (Fig. ’D’).

⇒ Connect pre-tensioning jack to HP oil pump 94931 as shown in Fig. ’D’.

⇒ Shut relief valve ’EV’ and actuate HP oil pump till oil flows bubble-free at vent

screw 1.

⇒ Close vent screw, tension foundation bolt with 1500 bar and keep pressure

constant.

Piston 3 of the pre-tensioning jack must never exceed the red limiting groove ’BN’

(Fig. ’D’).

Check with feeler gauge through slot ’KO’ if there is any clearance between nut 4

and bedplate 5.

Should a clearance be found, nut 4 must be tightened down onto its seating with

round bar ’RS’ while the pressure is kept at 1500 bar (check with feeler gauge).

Subsequently lower the pressure to ’0’ and remove the pre-tensioning jack.

Remark: If all foundation bolts have completely loosened and have to be ten-

sioned again, then follow as described in section 4.

RS

KO

6/7

D

94934a

3

x

94931

EV

94934a

012.949/05

2

5

4

13

BN

1

94935

Checking the Foundation Bolts

2010

CHECK

Loading...

Loading...