Maintenance

5552−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 3

Key to Illustrations:

1 Servo oil pump 12 Gear wheel

2 Screw 13 Spray nozzle

3 Screw 14 Cover

4 Pump support 15 Screw

5 Shaft 16 Screw

6 Pinion 17 Parallel pin

7 Housing 18 O-ring

8 Snap ring

9 Bearing bush MA Mark

10 Copper rod SB Shearable overload protection

11 Spray nozzle (predetermined breaking point)

Overview

1. General 1/3...............................................

2. Removal of servo oil pump 1/3.............................

3. Spray nozzles 3/3..........................................

4. Fitting 3/3.................................................

1. General

Concerning the maintenance of the servo oil pump observe the instructions from

the manufacturer. The servo oil pump drive must be checked in accordance with

the Maintenance Schedule 0380−1 ’Supply Unit’.

In order to prevent damages in case of the blocking of a servo oil pump, shafts 5 are

provided with shearable overload protection ’SB’ (Fig. ’C’).

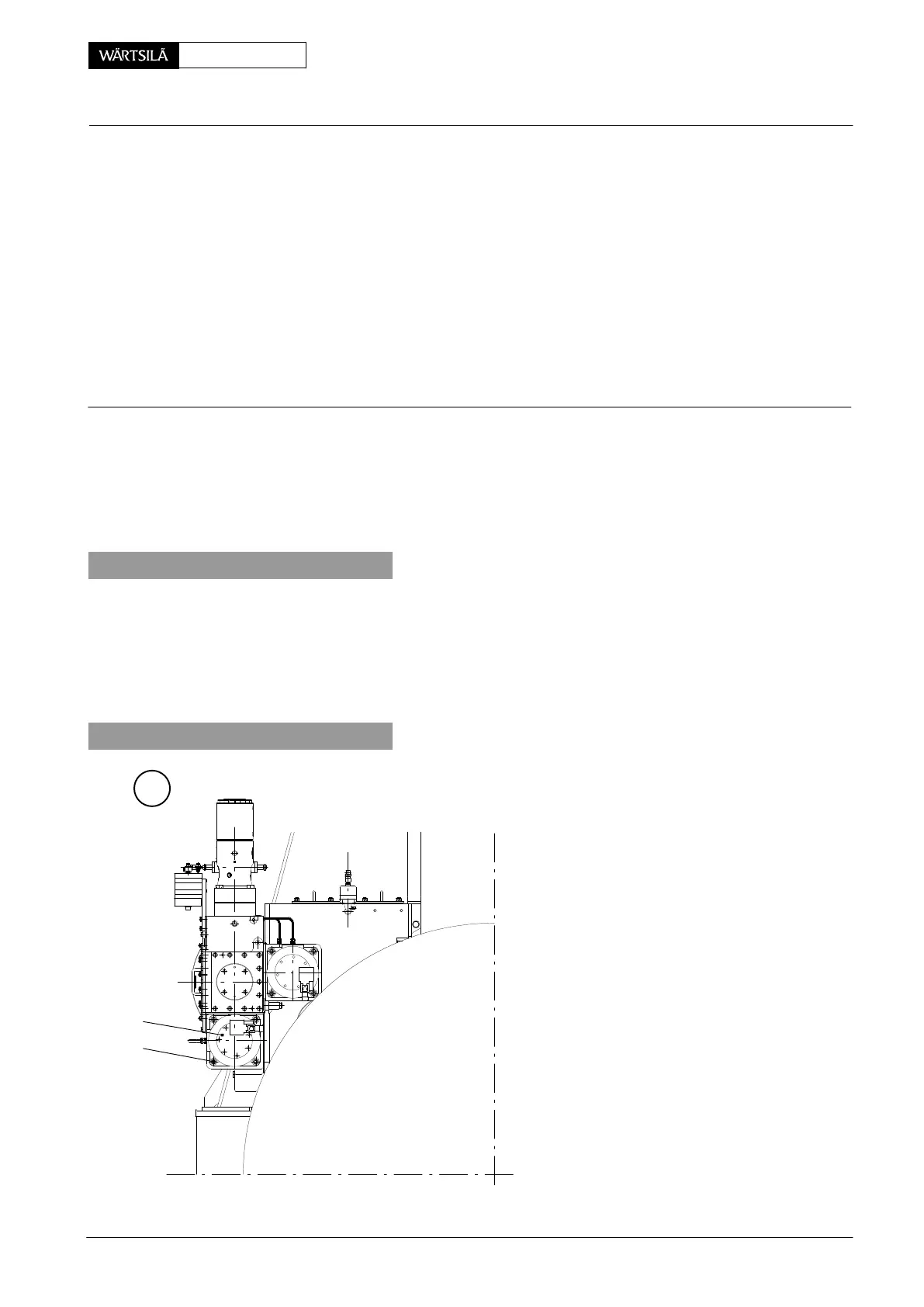

2. Removal of servo oil pump

A

012.976/05

2

1

⇒ Stop the engine.

⇒ Shut the stop valve after automatic filt

(see 5551−1 in the Operating Manua

⇒ Remove electrical connections fro

servo oil pump 1 to be removed.

⇒ Remove the corresponding pipings.

⇒ Loosen screws 2 and remove the serv

oil pump in horizontal direction.

upply Unit

emoval and Fitting of Servo Oil Pump and Servo Oil Pump Drive

2010

Loading...

Loading...