Maintenance1132−2/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

12/ 17

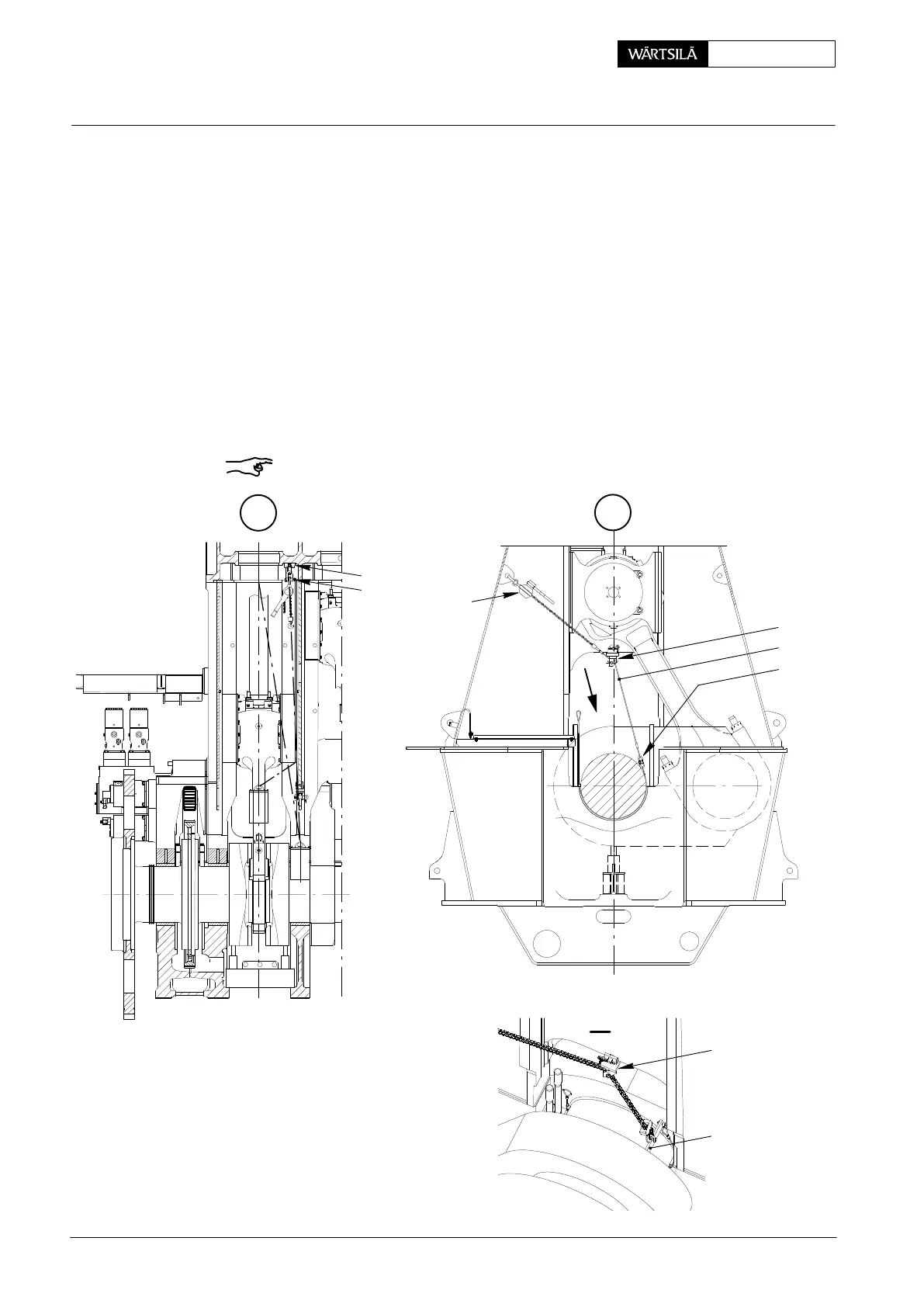

5.4 Turning out lower bearing shell No. 2 and following

D Turn crank to exhaust side approx. 90_ after T.D.C.

D Place working platform.

D Crankshaft lifted up by approx. 0.2 mm (see paragraphs 5.1 and 5.2).

⇒ Remove Allen screw 5 from bearing girder on exhaust side. Fasten turning-

out device 94118a to bearing shell 4a (see detail in Fig. ’J’), lead both ropes

along the lateral edges of the bearing shell to the other side and connect them

with device 94119b.

⇒ Fit assembling and dismantling device 94117 to column by means of its prop-

er pin, which must be secured with a double spring clip.

⇒ Pull rope 94120a through the assembling and dismantling device and hook

the ends in manual ratchet H

1

and the device.

⇒ Turn out bearing shell using manual ratchet H

1

until transportation tool

94116a (WLL 50 kg) can be fitted.

Remark: If necessary, manual ratchet H

1

can be hooked straight into the device

for turning out the last part of the bearing shell.

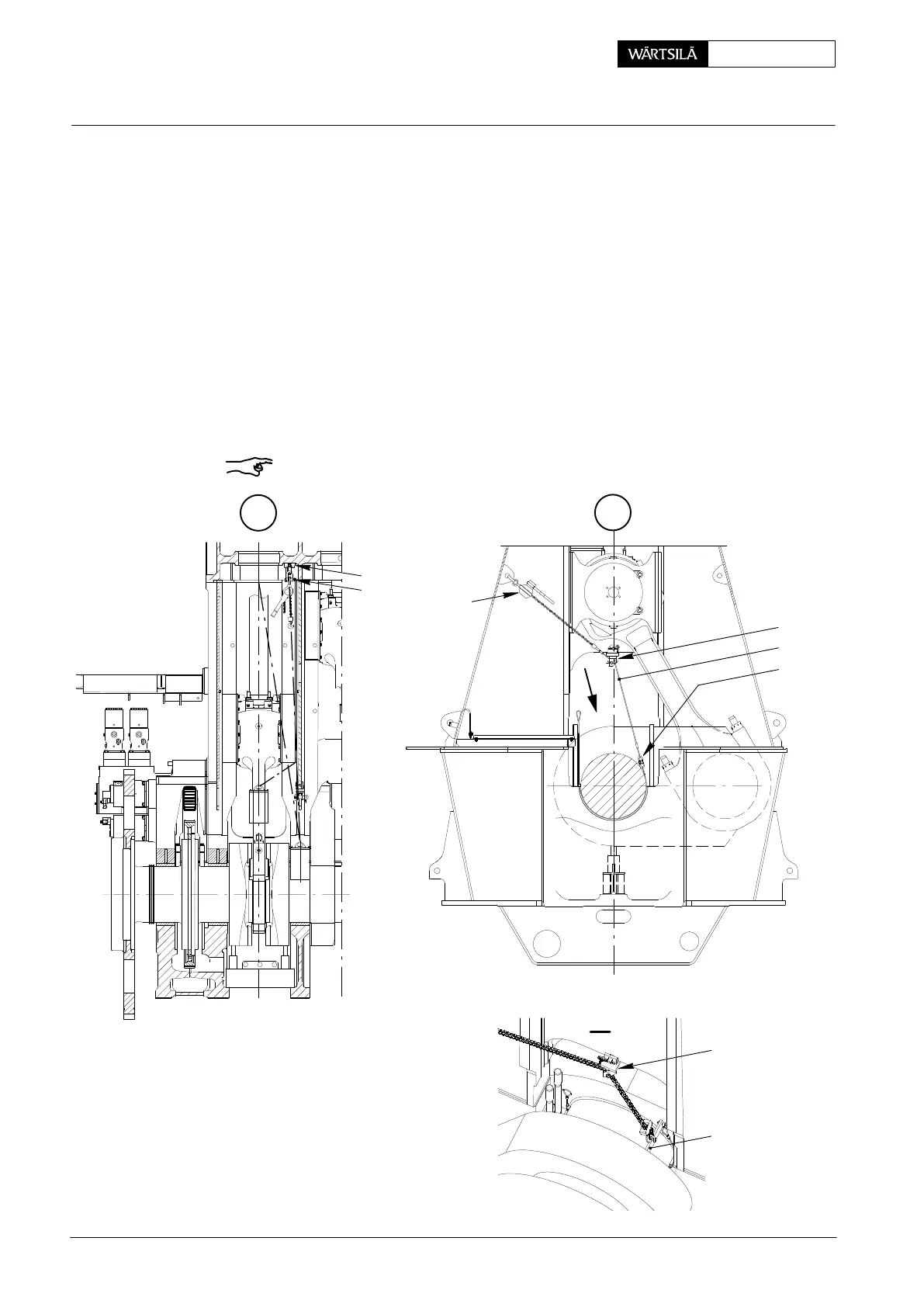

K

018.608/09

L

94120

94119b

94117

94119

I

I

H

1

018.605/09

94332

94332a

94117

2010 / 50−D

Removal and Fitting of a Main Bearing

Loading...

Loading...