Maintenance

9223−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

5/ 22

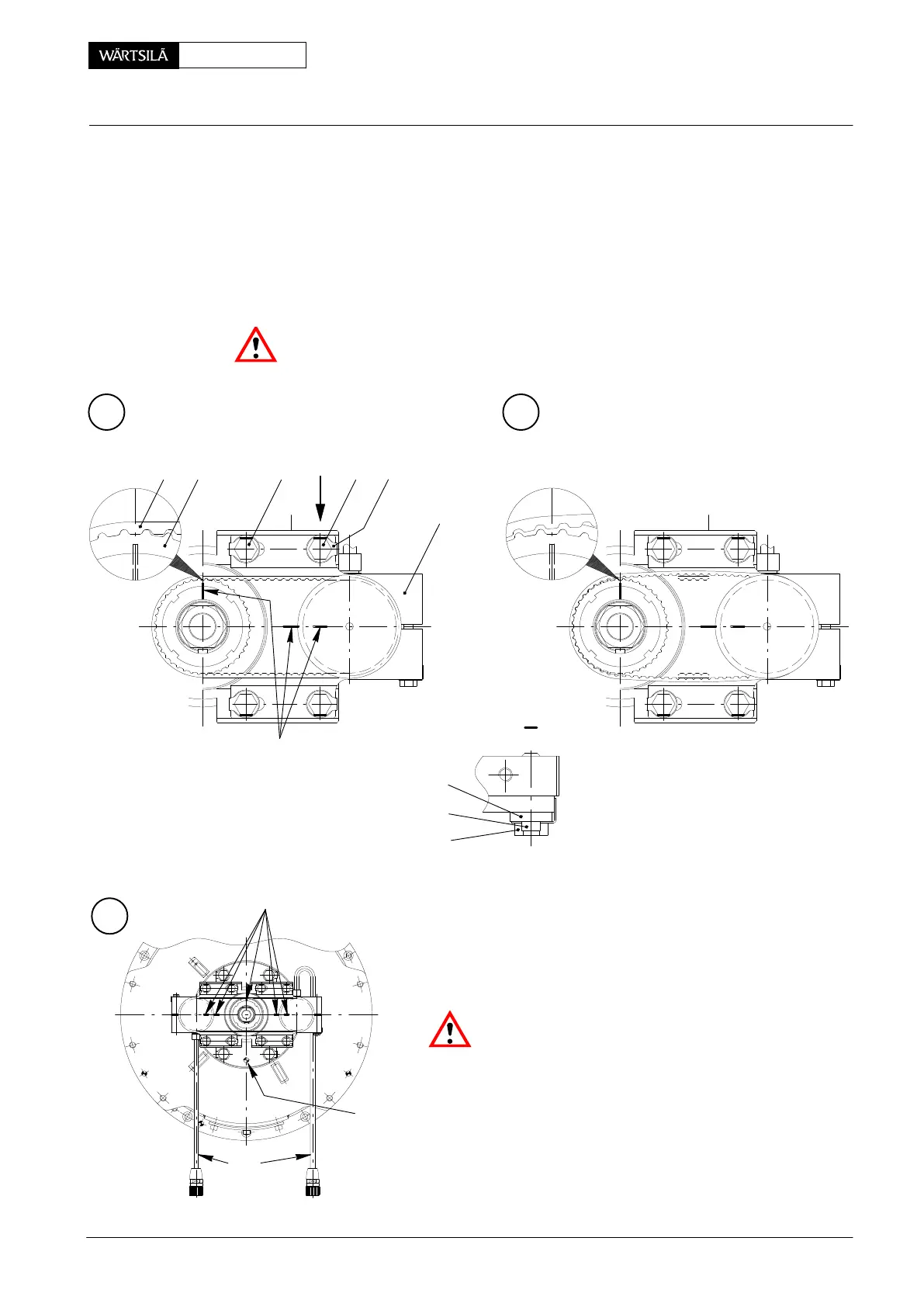

⇒ In order to align toothed belt 9 on its running track, turn the crankshaft one to

two revolutions with the turning gear.

⇒ Recheck belt tension according to Fig. ’G’ and ’H’ as well as marks ’MK’. Re-

peat tensioning procedure if belt slackened after crankshaft has been turned

or if marks ’MK’ are not matching.

⇒ Adjust and bend the long lugs of locking plates 17 according to Fig. ’G’.

⇒ Tighten all screws 15 and 15a with a torque of 16 Nm and lock them.

Attention! Always use new locking plates, bending them once only!

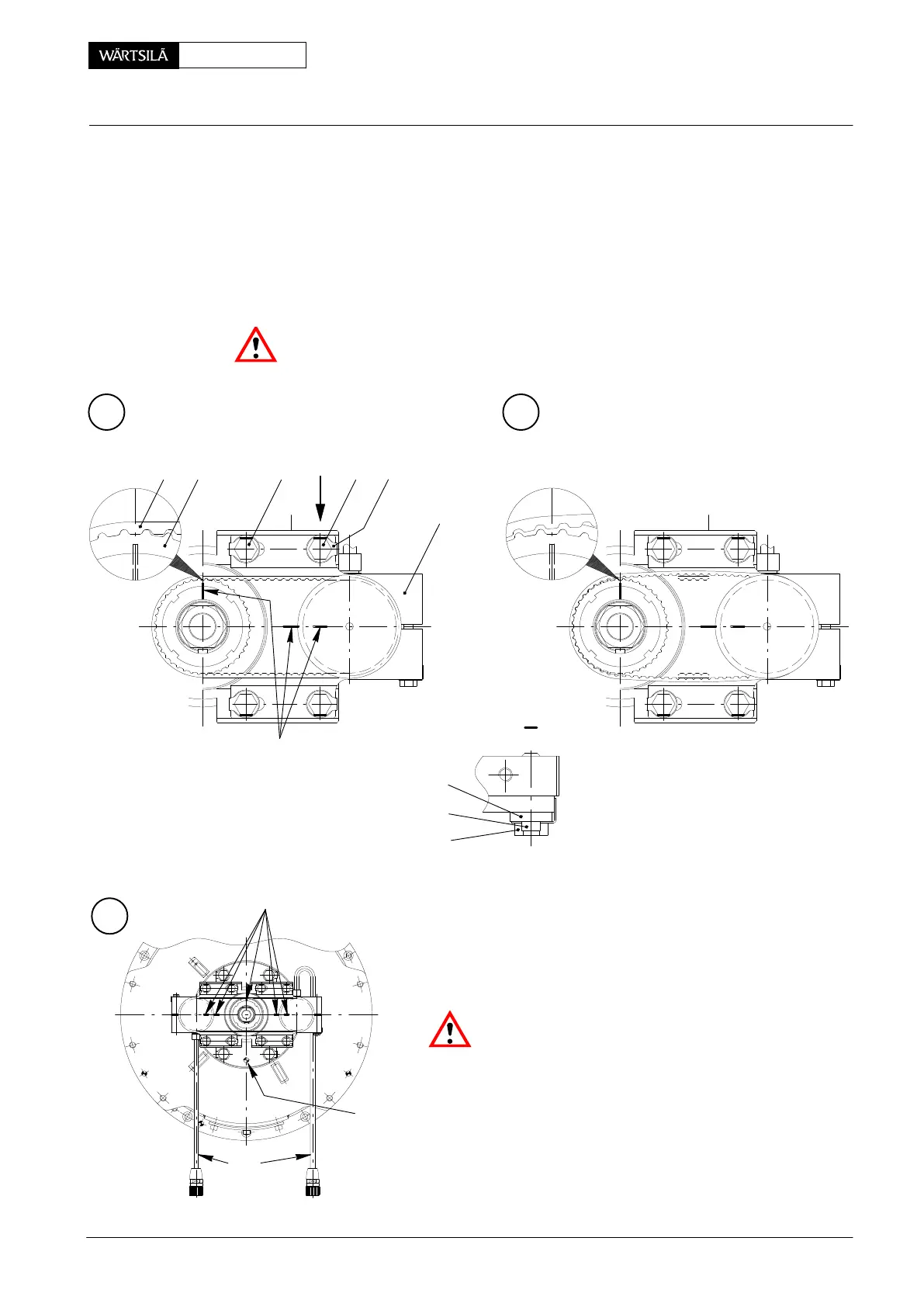

3.3 Outer shaft encoder

Fitting the outer shaft encoder 13 is carried out analo

gously to the inner one.

Attention! When fitting shaft encoders, toothed belt

or crank angle sensor drive (section 7) always pa

attention to the following points:

D Crankshaft at T.D.C. of Cyl. No.1.

D Bore for locating pin 58 of the crank angle senso

drive pointing downwards as shown in Fig. ’I’.

D Mark ’MK’ (T.D.C. 1) of gear wheel 18 pointing up

wards as shown in Fig. ’G’ and all other mark

aligned according to Fig. ’I’.

008.733/01

008.732/00

008.731/00

T.D.C. 1

008.731/00

G

I

9

I

18 15a

19

17

H

TOOTHED BELT

TENSIONED

TOOTHED BELT

LOOSE

MK

15 17

15a

I

MK

58

16

T.D.C. 1

SK

2011

rank Angle Sensor Unit: Dismantling, Assembling and Adjusting

Loading...

Loading...