Maintenance

1112−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 3

Tools: Key to Illustrations:

1 Feeler gauge 94122 1 Vent screw 11 Nut

1 Pre-tensioning jack 94145 2 Cylinder 12 Conical socket

1 HP oil pump 94931 3 Piston 13 Seating washer

2 Hydr. distributors 94934a 4 Nut

1 HP hose 94935 5 Bedplate

6 Foundation bolt BN Limiting groove

7 Foundation fitted stud EV Relief valve

8 Sleeve KO Slot

9 Chock RS Round bar

10 Ship’s foundation plate SA Gap

1. General

The pre-tension of the foundation bolts (holding down studs) must be checked at

longer intervals e.g. during overhauls (see 0380−1).

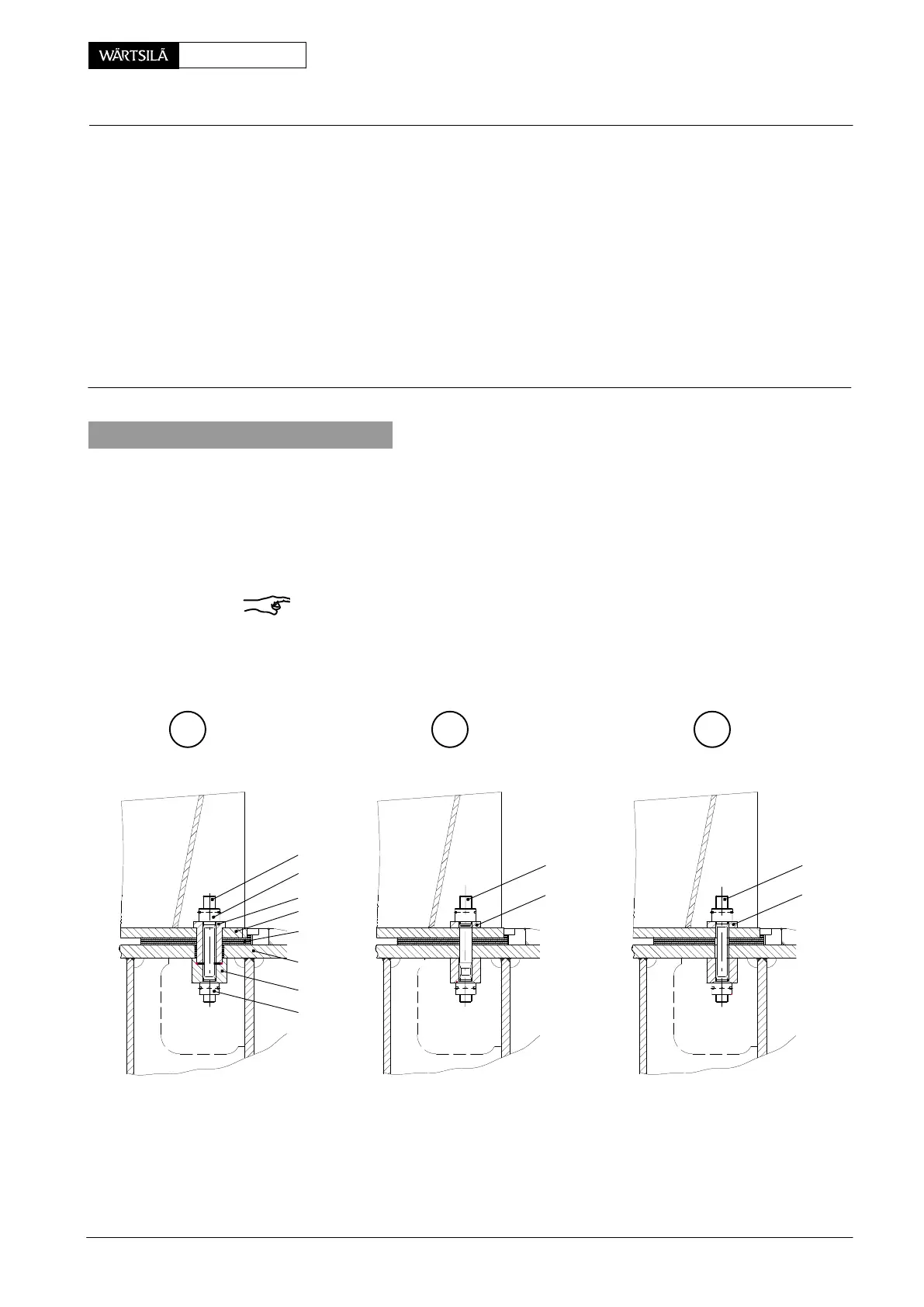

In the area of the thrust bearing the foundation may be fastened with foundation

bolts 6 and sleeves 8 (Fig. ’A’) or with foundation fitted studs 7 (Fig. ’B’).

The remaining area is fastened with foundation bolts 6, however without sleeves 8

(Fig. ’C’).

Remark: Pay attention to the General Application Instructions 9403−4 for the

hydraulic pre-tensioning jacks.

A C

012.948/05

6

13

7

B

10

12

11

8

5

4

9

13

6

edplate and Thrust Bearing

hecking the Foundation Bolts

2010

Loading...

Loading...