Maintenance

1132−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

3/ 3

4. Tensioning the waisted studs

After fitting the main bearing cover (1132−2), waisted studs 3 are to be tensioned

as follows:

⇒ Set-up double pre-tensioning jacks 94114b as described in section 2.

⇒ Start up hydraulic unit 94942.

⇒ Close vent screws 6 on the jacks as soon as oil flows bubble-free.

⇒ Actuate hydraulic unit, adjust pressure to 1000 bar and keep it constant.

⇒ Tighten all nuts 4 with round bar ’RS’ till firmly seated.

No clearance must be at hand between main bearing girder 1 and main bearing

cover 2 (Fig. ’B’)!

⇒ Mark the position of nuts 4 against bearing cover = 1

st

step.

⇒ Raise pressure to 1500 bar at the hydraulic unit and keep it constant.

⇒ Tighten all nuts 4 with round bar ’RS’ till firmly seated; check through slot ’KO’

using feeler gauge 94122.

⇒ Release pressure to zero at the hydraulic unit and then remove both double

pre-tensioning jacks.

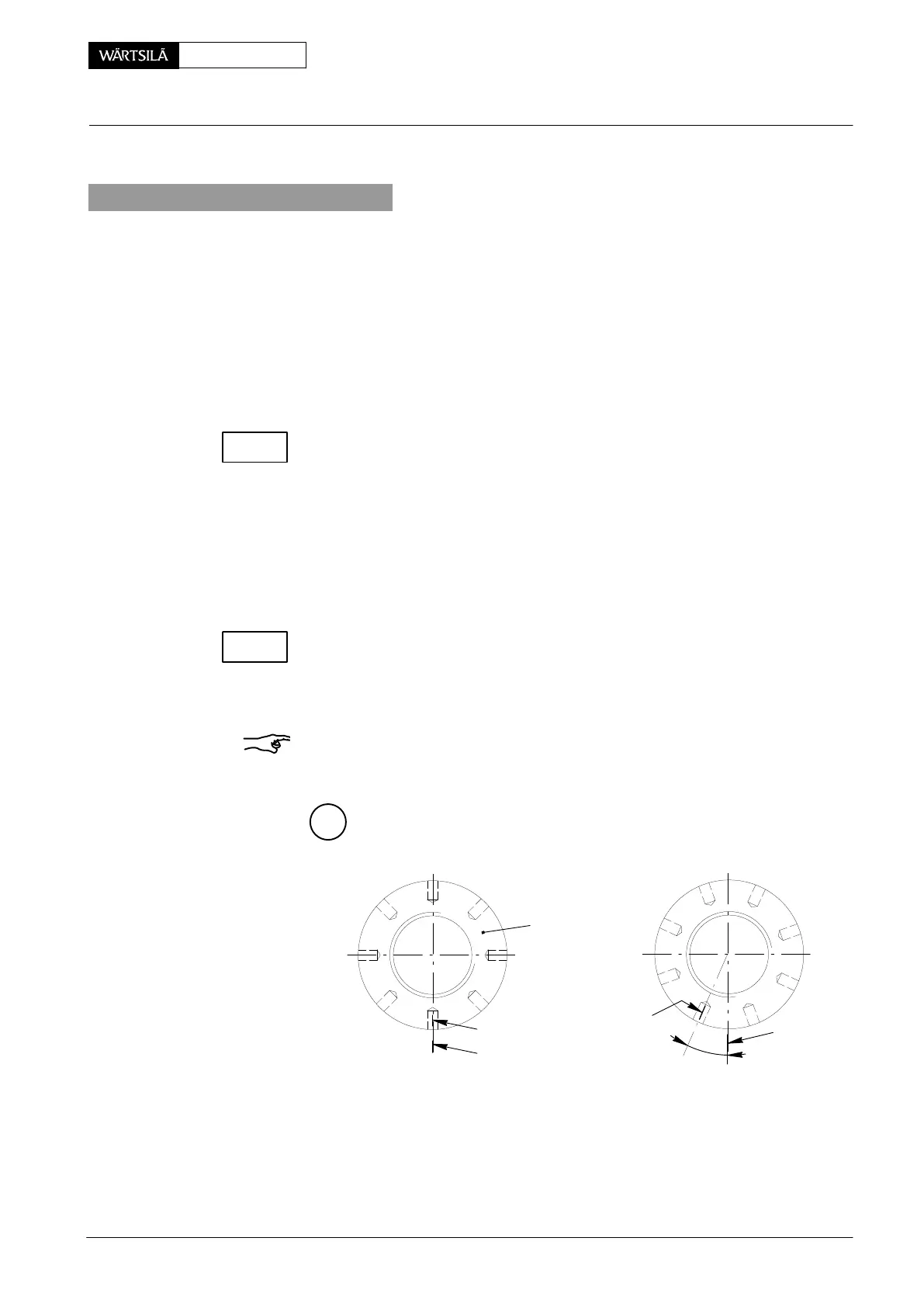

Check if all the nuts have been turned by approx. the same value, i.e. the tigh-

tening angle should be 20_ between the 1

st

and 2

nd

step. If bigger differences

occur the tensioning procedure must be repeated.

Finally check the vertical clearance by means of special feeler gauge 94123 (see

Clearance Table 0330−1 ’Crankshaft and main bearing’).

Remark: All main bearing clearance values are valid only with tightened tie rods

and waisted studs.

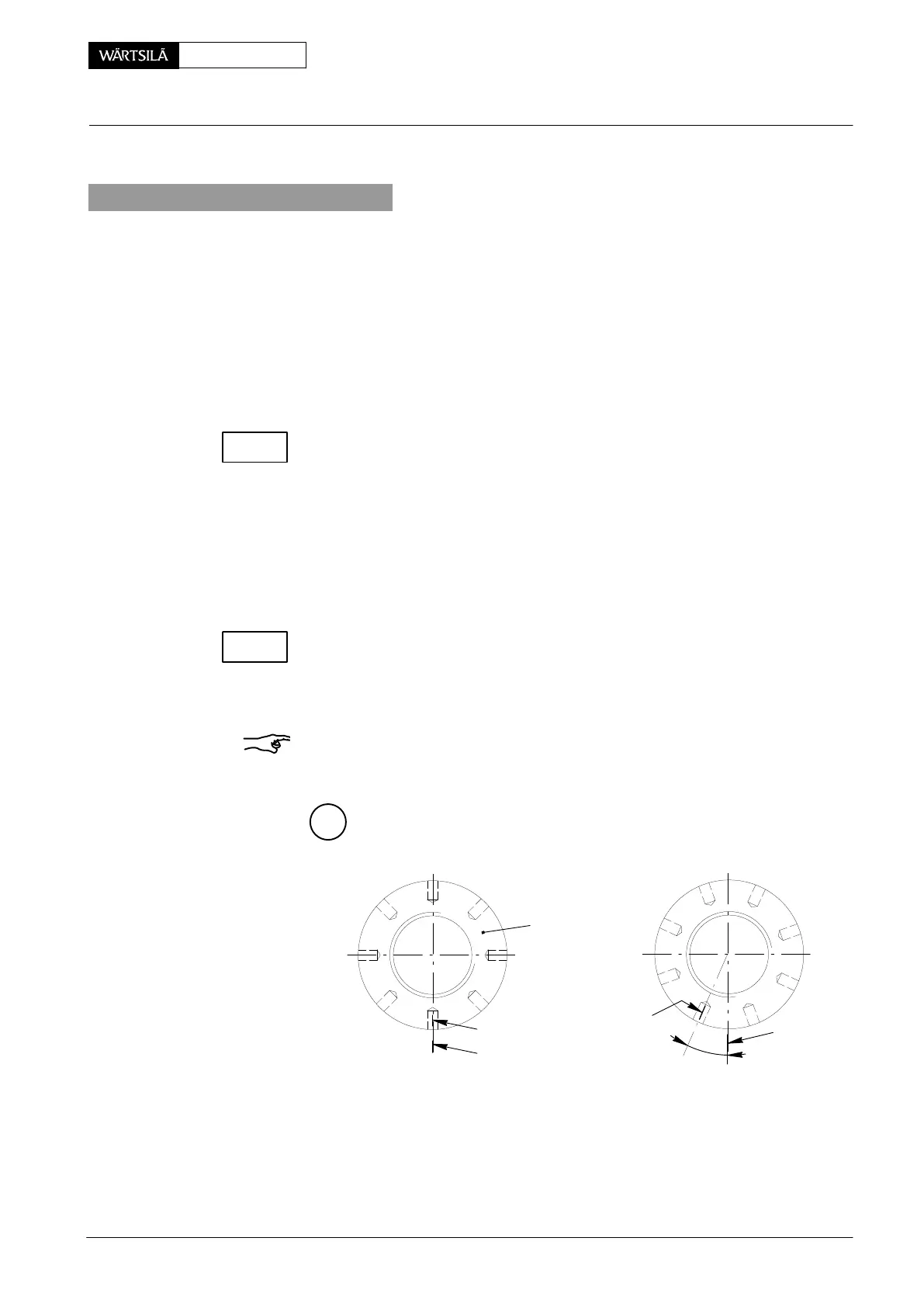

1

ST

STEP

2

ND

STEP

D

y

x

4

013.432/0

009.758/02

y

TIGHTENING

ANGLE

x

50−D / 2010

Main Bearing: Loosening and Tensioning of Waisted Studs

CHECK

CHECK

Loading...

Loading...