Maintenance

1132−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

1/ 3

Tools: Key to Illustrations:

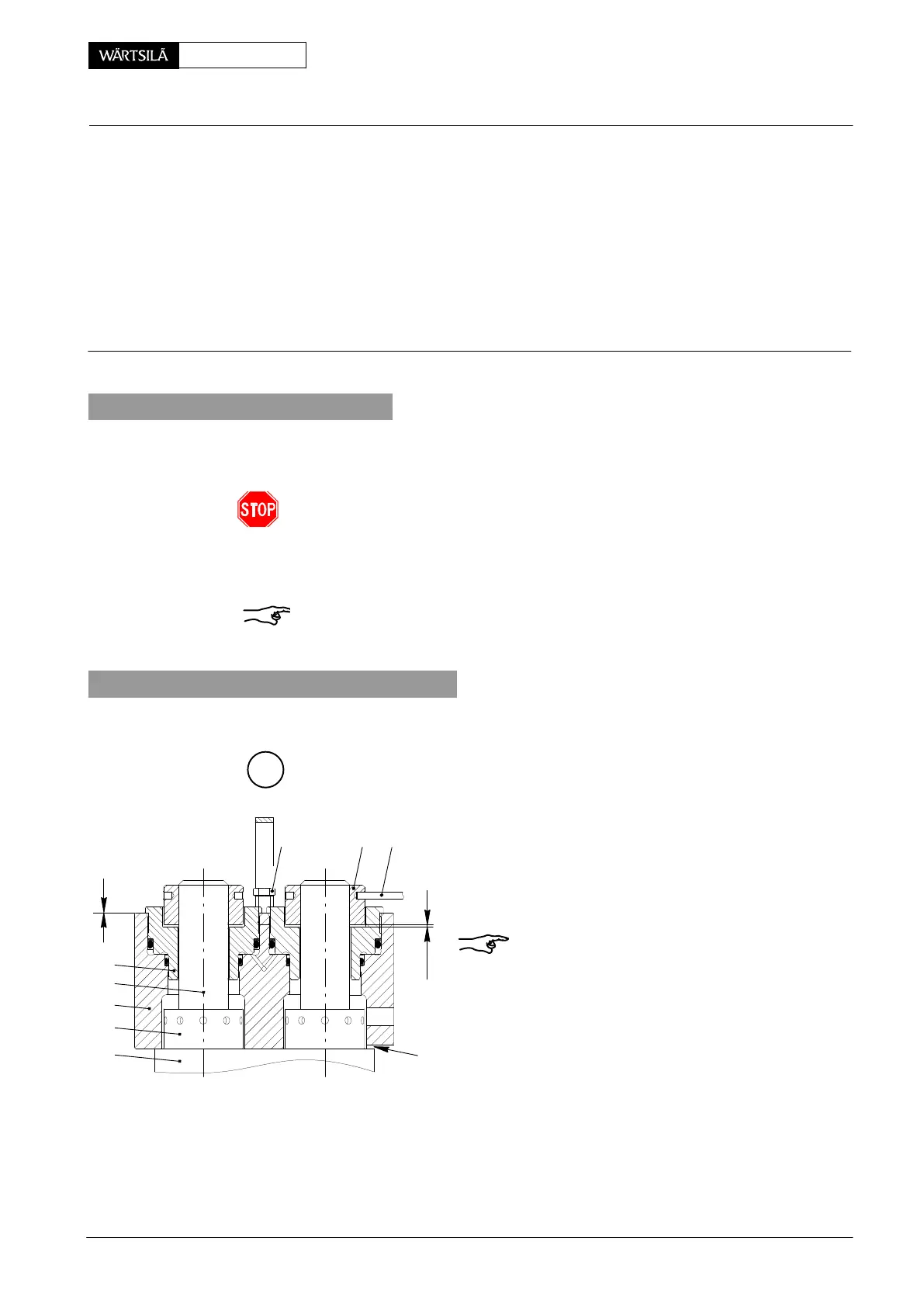

2 Double pre-tensioning jacks 94114b 1 Main bearing girder

1 Feeler gauge 94122 2 Main bearing cover

1 Special feeler gauge 94123 3 Waisted stud

1 Connection block 94934 4 Nut

1 Hydr. distributor 94934a 5 Round nut BN Limiting groove

2 Coupling elements 94934g 6 Vent screw KO Slot

3 HP hoses 94935 7 Double cylinder RS Round bar

1 Hydraulic unit 94942 8 Piston SA Gap

1. General

If provided, the temperature monitoring for piston cooling must be first removed

from the main bearing cover prior to set-up of double pre-tensioning jacks 94114b.

Attention! Thrust device 94110 must not be installed for loosening and tensioning

of the waisted studs!

Prior to screwing the nuts onto the waisted studs, the threads and nut seating sur-

faces must be cleaned. Apply oil to the threads and pay attention to the free move-

ment of the nuts.

Remark: Pay attention to General Application Instructions 9403−4 for hydraulic

pre-tensioning jacks.

2. Set-up of double pre-tensioning jacks

⇒ Set-up double pre-tensioning jacks 94114

onto waisted studs 3.

⇒ Open all vent screws 6.

⇒ Press pistons 8 against double cylinders

with round nuts 5 until there is only little or n

clearance at ’x’.

Remark: For loosening the waisted stud

screw back the round nuts by approx. ¾ tur

(gap ’SA’).

For tensioning the waisted studs, the roun

nuts must lie on the piston.

⇒ Connect both double pre-tensioning jack

94114b with hydraulic unit 94942 as shown

Fig. ’B’.

A

018.685/09

RS

KO

3

SA

8

4

7

1

56

ain Bearing

oosening and Tensioning of Waisted Studs

50−D / 2010

Loading...

Loading...