Maintenance

9223−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

17/ 22

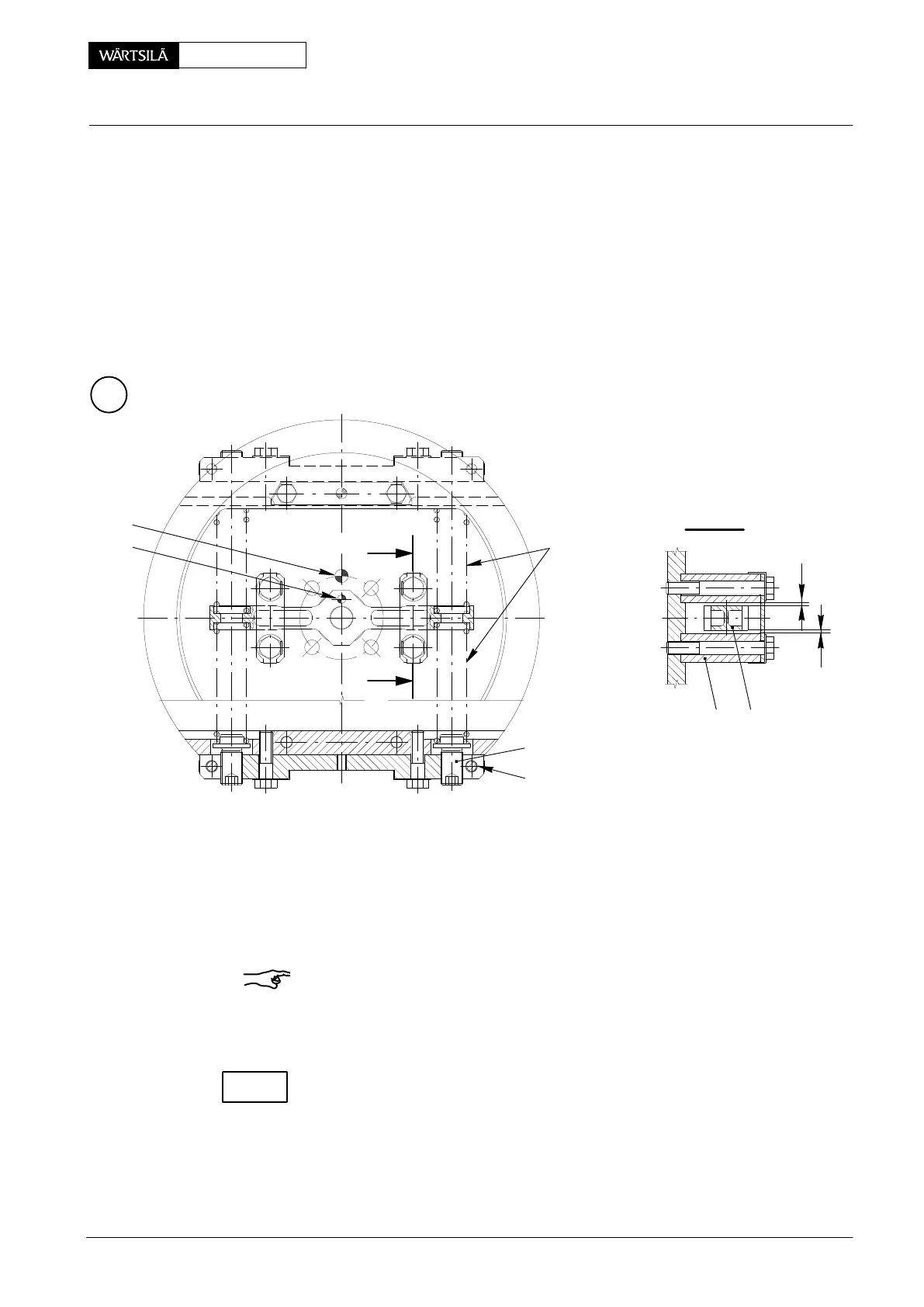

8.5 Adjusting the compression spring

⇒ By means of synchronously adjusting screws 54 (i.e. if one of the adjusting

screws is screwed-in by e.g. ½ turn, the opposite one must be screwed-out by

½ turn) move the relevant compression spring pair 42 until lever 43 shows the

same distance ’x’ between the stops on both sides (centering lever).

For measuring use feeler gauge 94122.

⇒ Tighten all clamp screws 55 with a torque of 35 Nm and lock them.

008.752/01

008.749/01

Z

II

II

II - II

42

55

4356

x

x

54

40

50

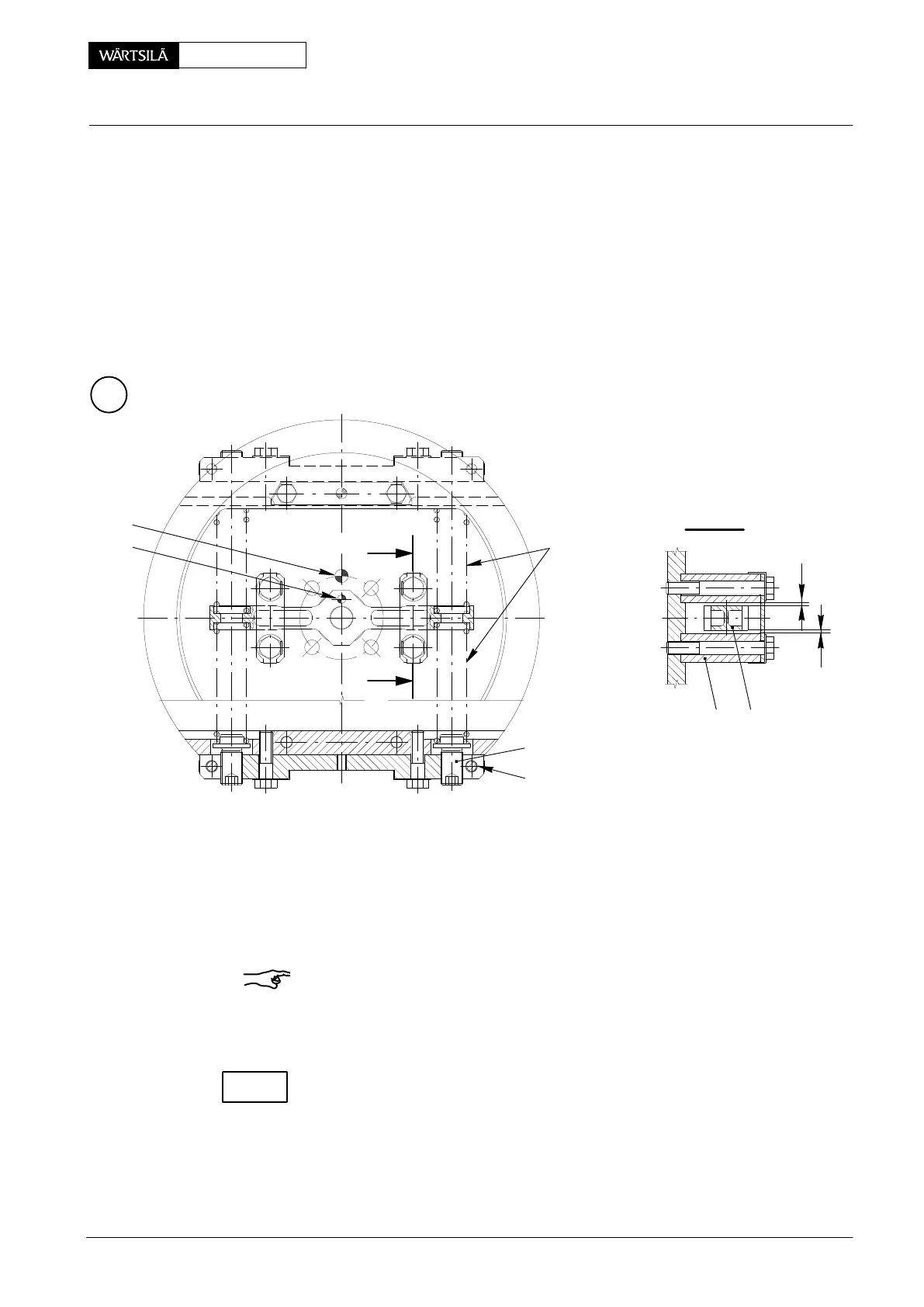

8.6 Fitting the connecting unit (Fig. ’W’)

⇒ Fit waisted screw 20 and screw 44 with new locking plates. Tighten and lock

the latter (Fig. ’U’ view I).

Remark: Screw 44 must not press against waisted screw 20!

⇒ Fit connecting unit 49 and screws 48 together with new locking plates 48a,

applying MOLYKOTE paste G to threads and seating surfaces.

⇒ Tighten screws 48 with a torque of 60 Nm and lock them.

Locating pin 40 and locating pin 50 must point upwards on Cyl. No.1 at T.D.C. ac-

cording to Fig. ’W’ and ’Z’!

2011

rank Angle Sensor Unit: Dismantling, Assembling and Adjusting

CHECK

Loading...

Loading...