Maintenance2722−1/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 8

2. Checking an injection valve

Before commissioning the instructions and directions of the test bench manufac-

turer must be observed.

Remark: The work station must be clean; welding and grinding should not be done

nearby!

From time to time check the pressure gauges of the test bench with a master pres-

sure gauge and adjust them if necessary.

⇒ Remove combustion residues and clean nozzle tip externally with a brass

wire brush.

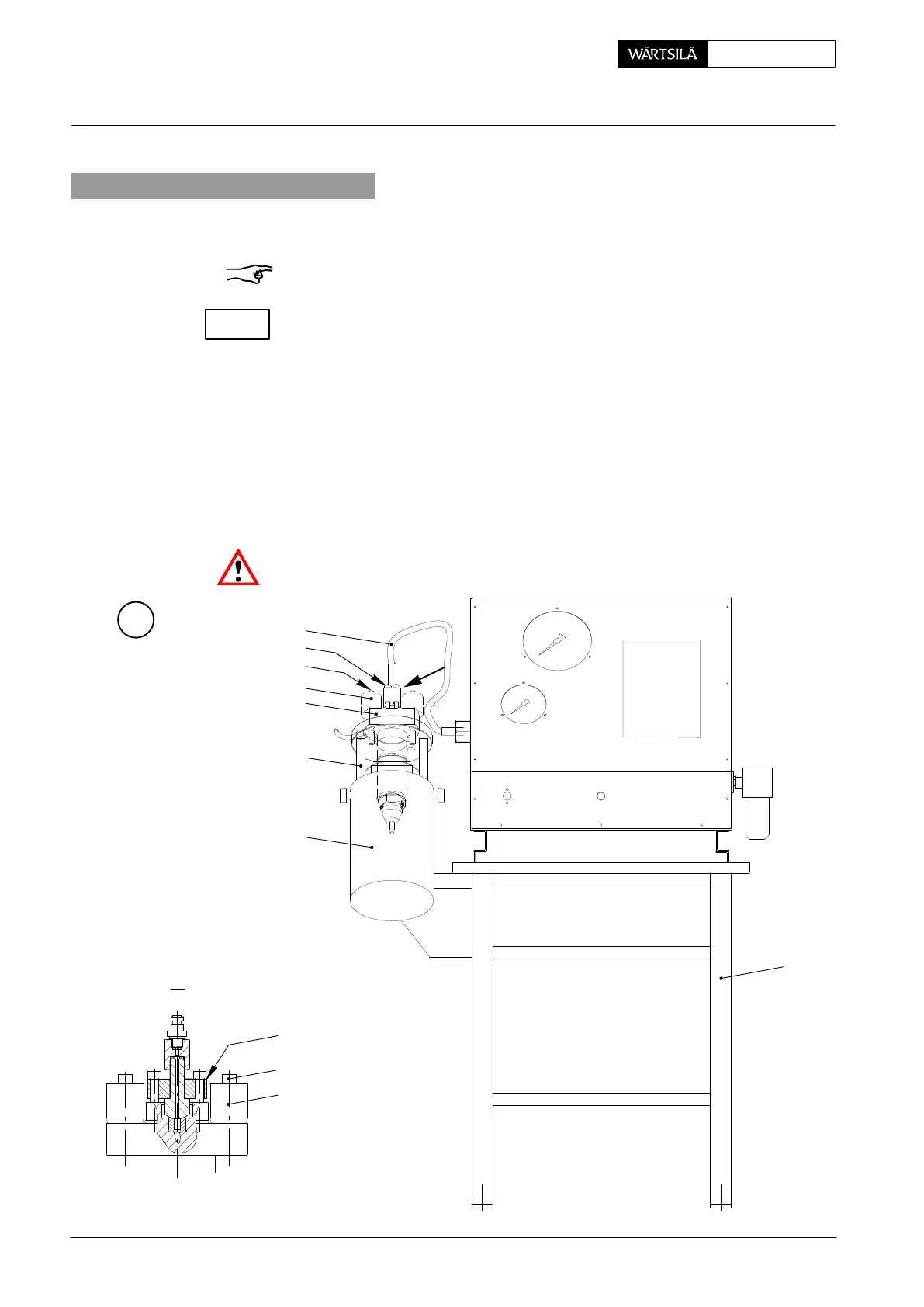

⇒ Place injection valve 1 with nozzle tip pointing downwards into support 19 of

test bench 94272 and fasten it with two Allen screws 2 and spring cages 23.

⇒ Tighten HP hose 20 of test bench with connecting piece 94272b.

⇒ Start the test bench following the proper manufacturer’s instructions.

⇒ Bring the injection valve to spray with a few short pump jerks, and then ob-

serve at what pressure the injection valve opens, applying slow, equal pump

jerks.

Danger of injuries! Never hold fingers or hands directly before the spray holes of

the nozzle tip!

A

20

9427

013.488/05

2

23

1

19

21

I

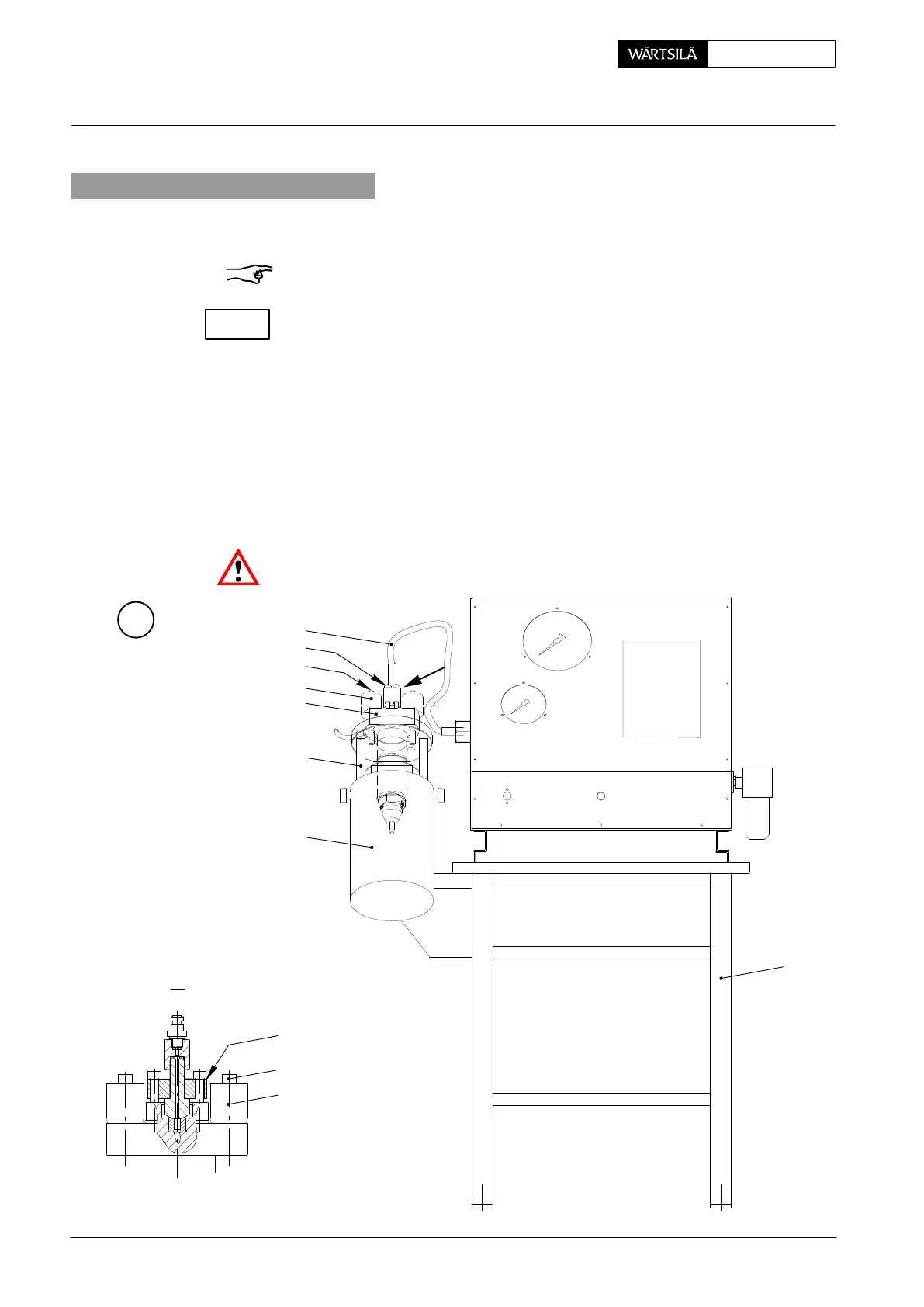

94272b

017.670/08

I

94272b

23

2

2011-12

Injection Valve: Checking, Dismantling, Assembling and Adjusting

CHECK

Loading...

Loading...