Maintenance4103−3/A1 RT-flex50-D

Wärtsilä Switzerland Ltd

2/ 5

1. General

Usually, the gear wheel on the crankshaft (from now on referred to as gear wheel)

is executed in one part and fitted as such on the crankshaft. If a damaged gear

wheel in the engine is to be replaced, it must be separated into two halves for dis-

mantling. In order to avoid damages, especially to the crankshaft, please ob-

tain the necessary instructions and recommendations for executing such disman-

tling work from the engine supplier or from Wärtsilä Switzerland Ltd.

For dismantling as well as for assembling a new gear wheel, dismount the inter-

mediate wheel of the supply unit.

The spare gear wheel is executed in two parts and must be fitted as described be-

low.

Remark: When ordering a 2-part spare wheel, please indicate the engine type, the

engine No., as well as the engine supplier. This data is necessary because the

centring diameter of the crankshaft is registered for mounting the gear wheel, and

the center hole of the 2-part spare wheel is manufactured according to these di-

mensions.

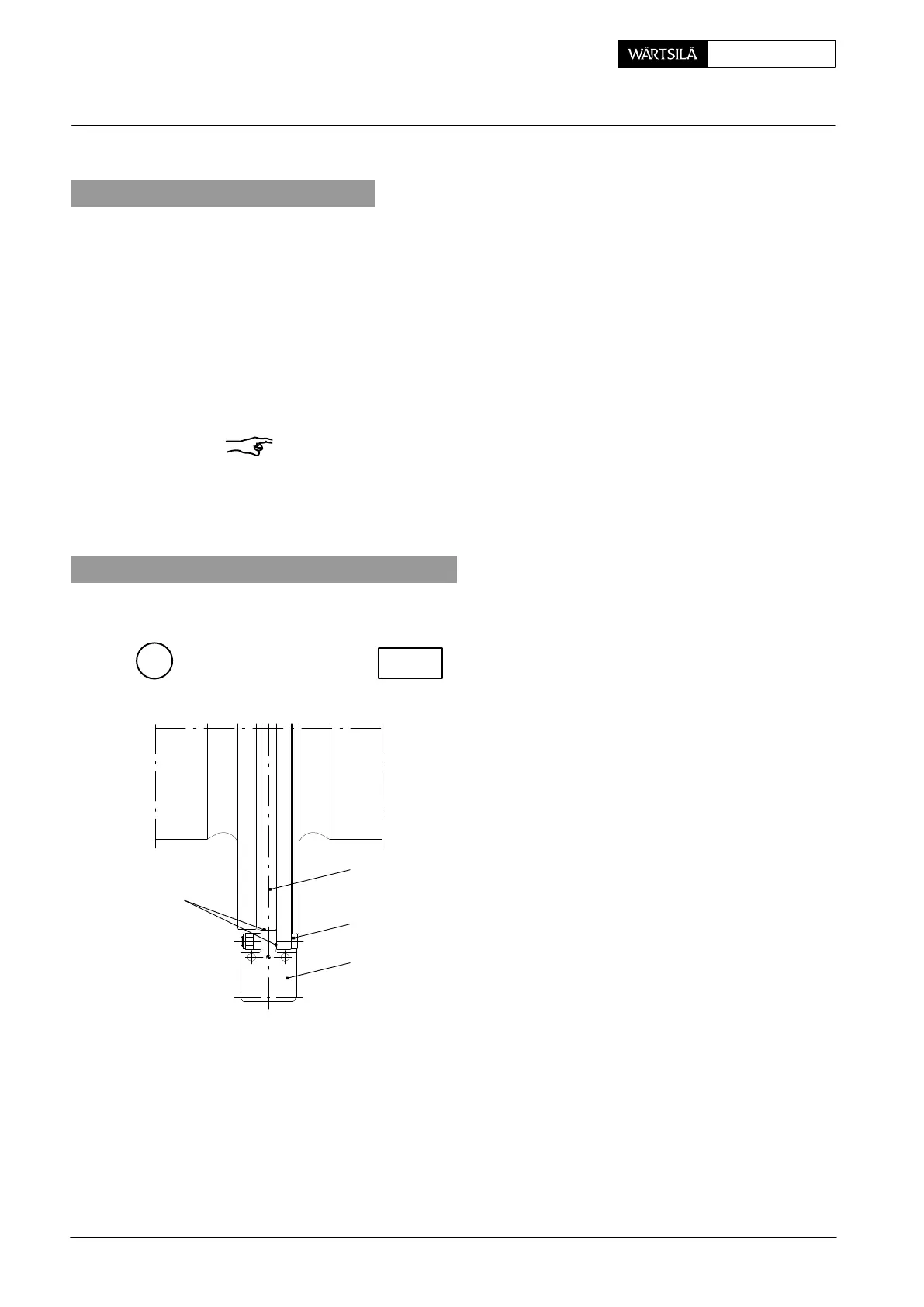

2. Preparing assembly of 2-part gear wheel

The undersize of center hole ‘d’ (Fig. ’A’) on 2-part ge

wheel 1 with regard to the corresponding centring diam

eter of the crankshaft has to be checked and recorde

beforehand. For measuring, the crankshaft, the ge

wheel, and the measuring instrument must have th

same temperature.

The undersize of the center hole with respect to the ce

tring diameter must be 0.05−0.12 mm.

D If the undersize is not within the mentioned tole

ance, the gear wheel must not be assembled, b

the center hole of the gear wheel has to be given a

appropriate aftertreatment (remachine / possib

bore and flame-spray, and machine to obtain th

correct diameter).

D Check whether there is a mark on the cranksha

flange 2 for fitting the gear wheel. For the assemb

the gear wheel partition must coincide with th

mark.

The designation DRIVING END, which is located o

the front of the gear wheel, must be on the side

the flywheel!

B

CHECK

2

001.171/97

1

DRIVING

END

DEGREASE

6

Replacing the Gear Wheel on the Crankshaft

2010

Loading...

Loading...