Maintenance

2722−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

7/ 8

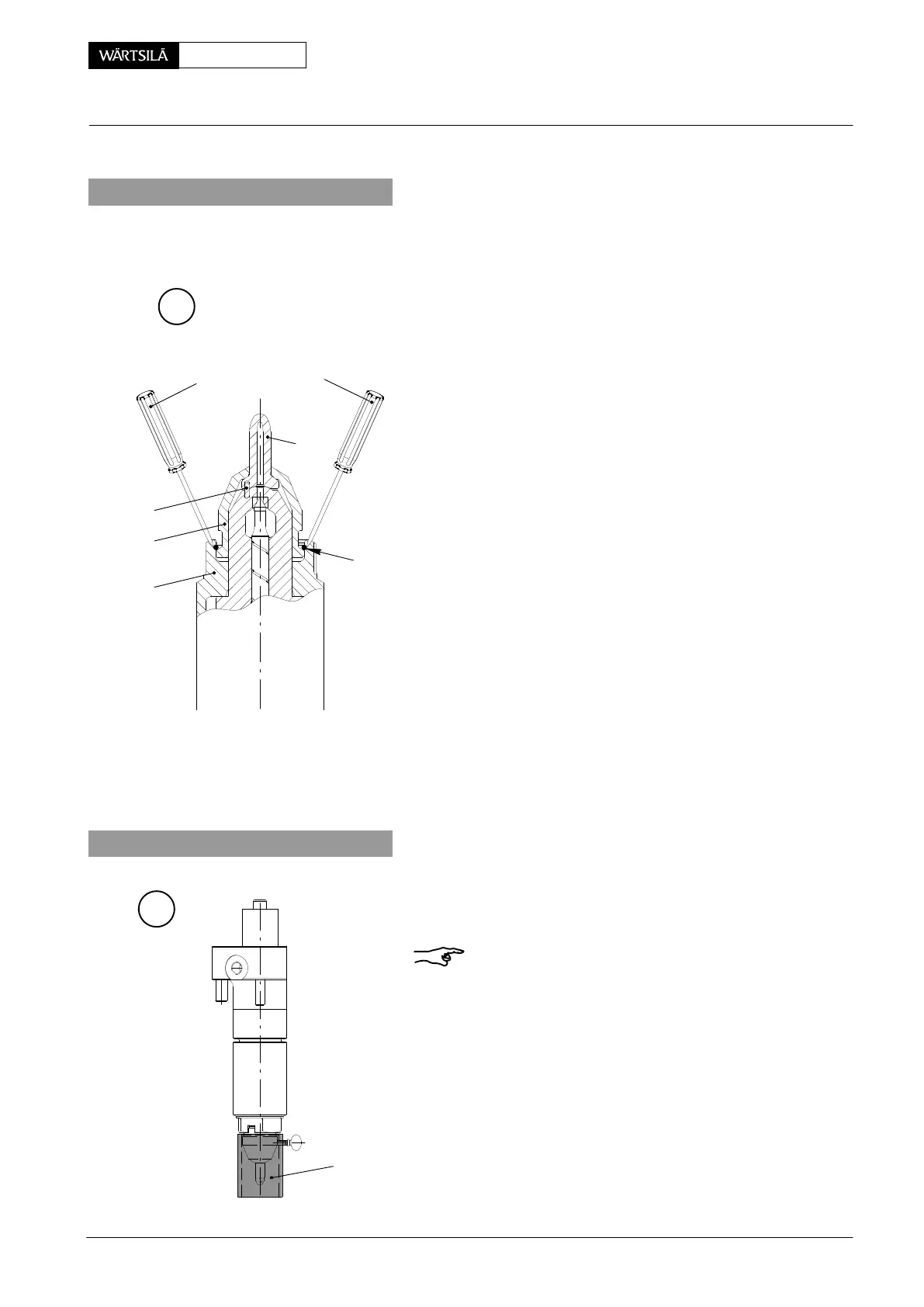

7. Replacing a nozzle tip

If nozzle tip 7 should be dismantled only, it is sufficient t

remove retaining sleeve 14.

7.1 Removal

⇒ Using two screw drivers inserted between both re

cesses in retaining nut 10, press snap ring 15 ou

of the groove in the retaining nut, whereby the re

taining sleeve can be withdrawn (Fig. ’C’).

Watch that the snap ring does not jump off unex

pectedly.

⇒ Remove nozzle tip.

7.2 Fitting

For fitting it is advantageous to clamp the injectio

valve on its flange into a vice (nozzle body 13 pointin

upwards), and then proceed as follows:

⇒ Clean all parts with clean diesel oil or kerosine an

blow them out with compressed air.

⇒ Place nozzle tip on the nozzle body whereby th

position is assured by dowel pin 16.

⇒ Put retaining sleeve 14 over the nozzle tip, an

press snap ring 15 into the groove of the retainin

nut by means of the screw drivers.

After replacing a nozzle tip the injection valve must b

checked and judged according to sections 2 and 3.

C

SCREW DRIVER

15

16

14

10

7

013.493/05

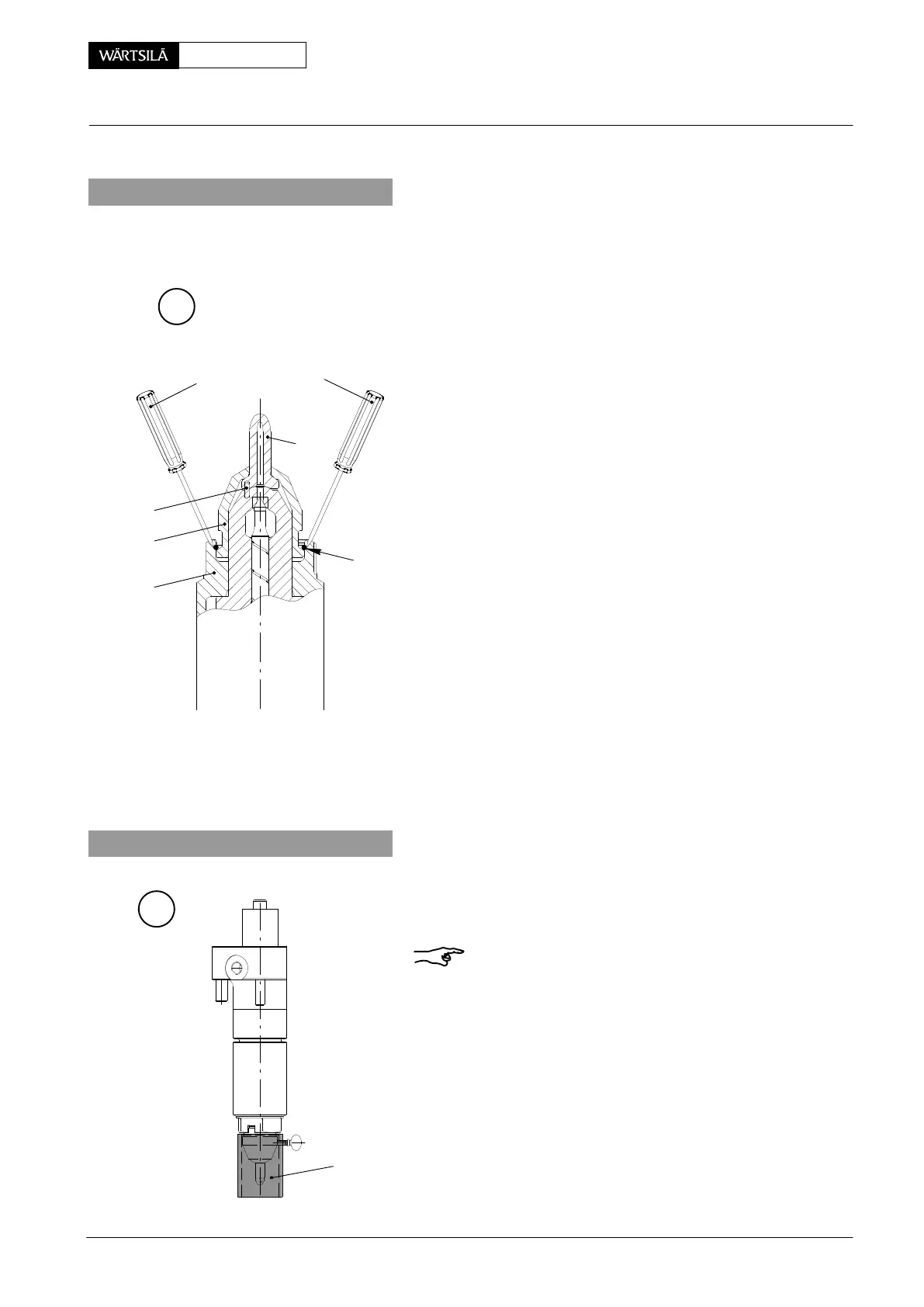

8. Protecting a nozzle tip

D

013.494/05

Remark: To protect the nozzle tip integrated in the in

jection valve against damage, always fit protection ca

94271 for transport, storage, etc.

94271

2010

Injection Valve: Checking, Dismantling, Assembling and Adjusting

Loading...

Loading...