Maintenance

0380−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

7/ 7

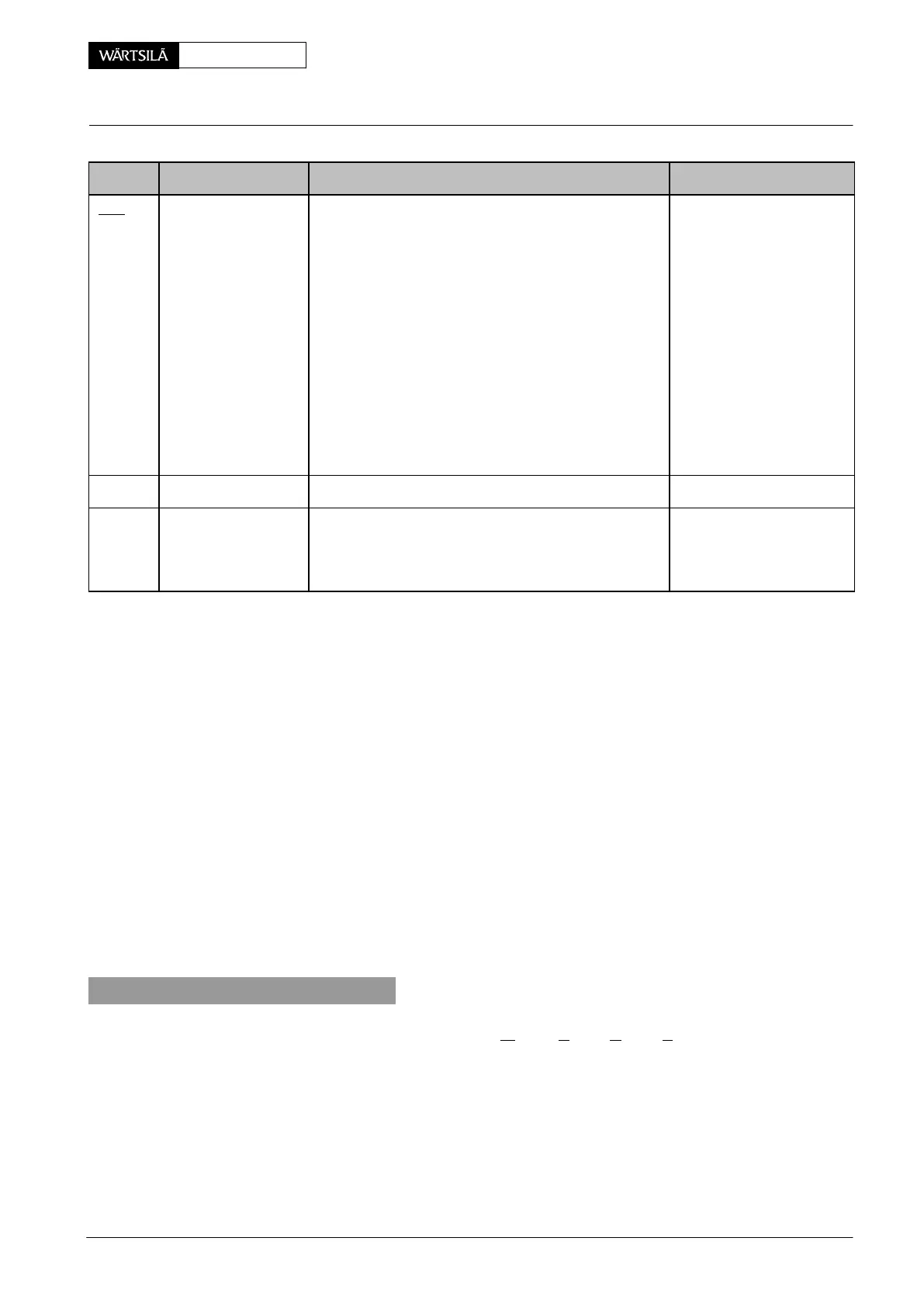

Group Component Work to be carried out Intervals

9

9223−1 Crank angle

sensor unit

− Check tension visually

Check cracks and wear of tooted belt visually

Visual lubricating oil check

3000 Op.h

− Replace toothed belt 24 000 Op.h

− Overhaul drive (ball bearing, sealing ring etc.)

and check shaft eccentricity of CAS drive

48 000 Op.h

− Check shaft eccentricity of CAS drive at every CAS exchange

− Replace crank angle sensor 48 000 Op.h

(only if new soft belt is

applied from beginning)

Oil mist detector − Follow manufacturer’s instructions half yearly

WECS electronic

components

− Replace FCM−20 module

(see Operating Manual 4002−4)

36 000−50 000 Op. h

− Visual cabling check quarterly

The indicated maintenance intervals must be taken as guidance and may vary

depending on the installation. The proper intervals are subject to the points men-

tioned below. Experience will show whether these intervals can be extended or

must be shortened.

− Environmental and operating conditions

− Heavy fuel oil and lubricating oil qualities (see OM 0710−1 and 0750−1)

− Engine load

− Fuel, lubricating oil and cooling water care (see OM 0720−1 and 0760−1)

− Overhaul according to Maintenance Manual

− Genuine spare parts used

− Engine monitoring

− Engines according to specifications of Wärtsilä Switzerland Ltd.

On the engine sectional drawings 0803−1, those parts are marked with group

numbers, as they are found in the Maintenance Manual.

Engine Control System WECS

Control works in the WECS (Wärtsilä Engine Control System) are described in the

following groups of the Operating Manual:

− Regular checks and recommendations 4002−4......................

− Engine control 4003−1............................................

2012-07

nspection and Overhaul Intervals (Guidelines)

Loading...

Loading...