Maintenance

3403−1/A1

RT-flex50-D

Wärtsilä Switzerland Ltd

7/ 8

5. Fitting the piston

Prior to fitting the piston, the following works must be carried out:

⇒ Remove piston rings with tensioning device 94338 (see 3425−1) and clean

piston exterior thoroughly (do not use any tools that might damage the sur-

face!).

Establish the height of the piston ring grooves (see Clearance Table 0330−1

’Piston and piston rings’).

⇒ Clean piston rings and measure them.

Remark: For refitting of used and new piston rings, follow strictly the instructions in

3425−1.

D When refitting used piston rings be sure to fit them in the same grooves

as before.

D Fit the piston rings in such a manner that their marking TOP is on top.

Check the piston top surface (see 3403−4).

Measure bore of cylinder liner (see 2124−1) and carry out any needed recondition-

ing to lobricating grooves and scavenge ports (see 2124−3).

⇒ Actuate the cylinder lubrication until oil flows from all the lubricating points.

D Piston rod gland and both distance holders 94345 must be mounted on the

piston rod (see 2303−1).

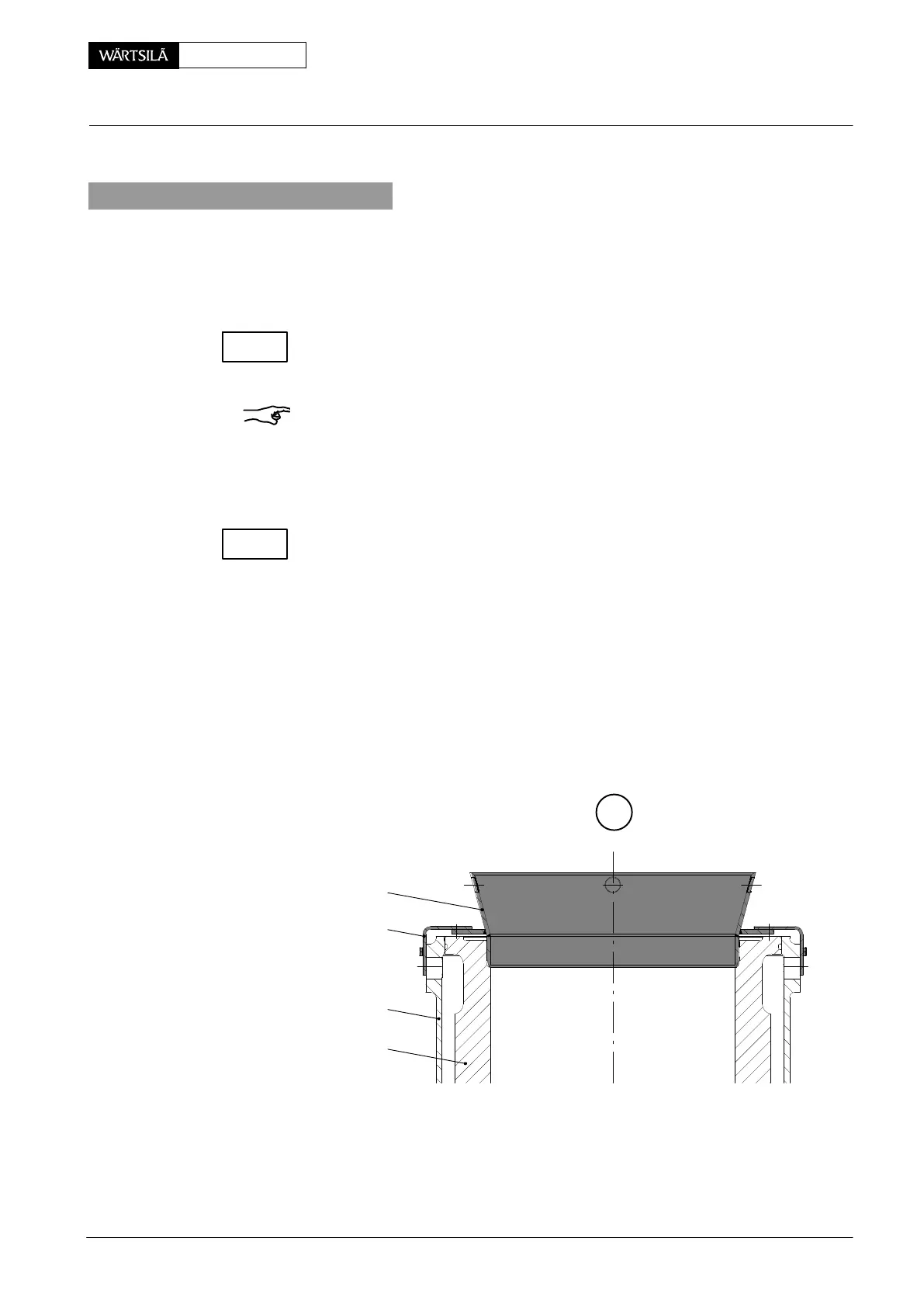

⇒ Place insertion funnel 94342 for piston rings on the water guide jacket 20.

D Suspension device 94341 must be fastened to the top of the piston crown.

⇒ Smear piston rings, piston skirt, piston rod and running surface in cylinder lin-

er lavishly with bearing oil.

H

94342

17

20

18

013.260/05

2010

Piston: Removal and Fitting

CHECK

CHECK

Loading...

Loading...